This article mainly gives you five methods of “how to join corrugated plastic sheets”. Everyone can collect it!

High performance adhesive specially formulated for polyolefin plastics such as polypropylene and polyethylene. This adhesive has good high and low temperature resistance. It is also not dependent on moisture or humidity and has excellent pot life. Ordinary glue doesn’t work at all. Be sure to use special polypropylene glue, which is a one-component synthetic resin composite glue with strong adhesion and stable performance. It is mainly used for PP corrugated bonding and large-area bonding of PP and other materials. The glue has moderate viscosity, can be cured at room temperature, is easy to use, and can be glued, dispensed, or hand-applied. After the glue is fully cured, it is transparent and soft, and plays the roles of bonding, positioning, sealing, and waterproofing.

The characteristic is that there is no trace on the surface, and the conjoined body is firm. Corrugated plastic products made of seamless welding technology have a smoother appearance and are suitable for high-quality production. It is conceivable that the cost is relatively high! Currently, very few companies in the world have this technology. Owning this technology is Polyflute coroplast manufacturer from China.

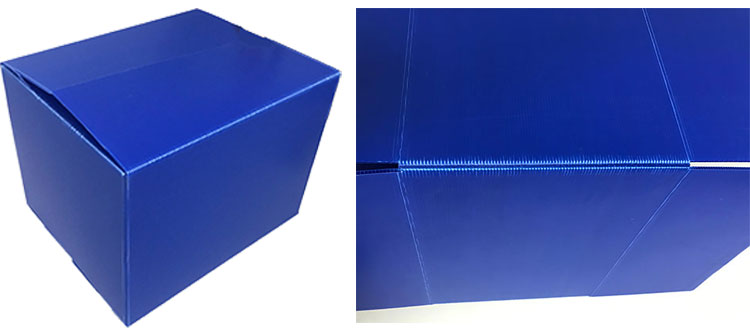

The ultrasonic vibration is transmitted to the corrugated plastic sheets along with the welding head. Due to the large acoustic resistance at the two weldments, local high temperature is generated, which melts the interface of the PP hollow sheets. Under a certain pressure, the two weldments can achieve a beautiful, fast and strong welding effect.

Nuts or other metals to be inserted into PP corrugated sheets workpieces. Firstly, place nuts or metal strips in the equipment, vibrate at high speed to embed the metal directly into the coroplast boards, melt the plastic at the same time, and complete the embedding after solidification.

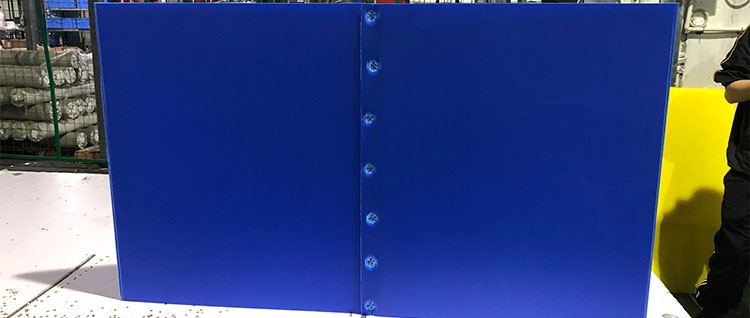

It is a mechanical fastener. Rivets are used to permanently secure workpieces. After the workpiece is fixed, it is necessary to destroy the rivet or the workpiece to separate the fixed workpiece. This is different from fasteners such as nails and screws. The method of fixing or connecting workpieces with rivets is called “riveting”. This connection method is very traditional, and the cost is very low.

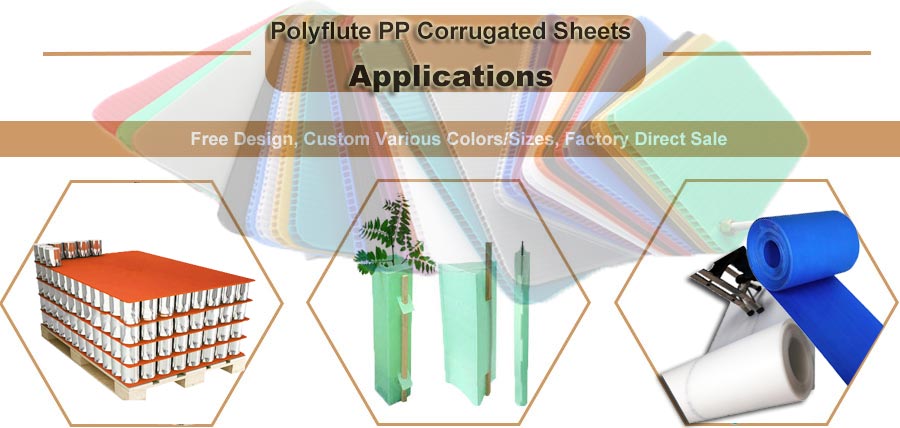

Corrugated plastic sheets are essentially polypropylene plastic made from three thin layers of polypropylene plastic substrate. The product consists of zigzag plastic layers sandwiched between two smooth plastic films – also known as PP hollow sheets. The layered structure of PP corrugated sheet makes corrugated plastic incredibly lightweight and shock-absorbing. It is also known as corflute panels, correx sheets, corex sheets, danpla sheets, fluted plastic sheets, coroplast boards, etc. Among them, Coroplast is the trade name of the world’s largest producer of corrugated plastics.

Correx plastic is a unique combination of durable, affordable, lightweight and flexible. This combination makes it very versatile and can be used for a variety of projects and displays.

Our company has been relying on technological progress, equipment updates and continuous training of employees to ensure the company’s position in the plastics industry. The company will continue to uphold the spirit of quality service and integrity management as the foundation of business operations, and sincerely cooperate with customers and help each other. We will stick to our credibility and promises, and serve our customers wholeheartedly.

This is the end of the introduction on how to join corrugated plastic sheets, thank you for watching!