How to connect corrugated plastic sheets is a problem that troubles many friends. Many friends try to use glue to connect pp corrugated sheets, but it is easy to separate them by hand. Because the corrugated plastic sheets are difficult to stick, they don’t soak at all and don’t allow the glue to get a good grip. If you want to know how to connect corrugated plastic sheets, be patient and read this article!

This corrugated plastic is used in many industries such as automotive, construction, displays, point of sale, railways, pharmaceutical packaging and is also widely used in the recyclable food plastic packaging industry. Its raw material is mainly polypropylene, an environmentally friendly and recyclable material. People also call corrugated plastic as coroplast, correx, corflute, danpla, polyflute, impraboard, infraboard, etc. This kind of hollow plastic board has a smooth surface. If you want to connect more than two boards together, you can’t bond them with ordinary glue.

It is a mechanical fastener. The rivet is used to permanently fix the workpiece. After the workpiece is fixed, it is necessary to destroy the rivet or the workpiece to separate the fixed workpiece. This is different from fasteners such as nails and screws. The method of fixing or joining workpieces with rivets is called “riveting”. This connection method is very traditional and very low cost.

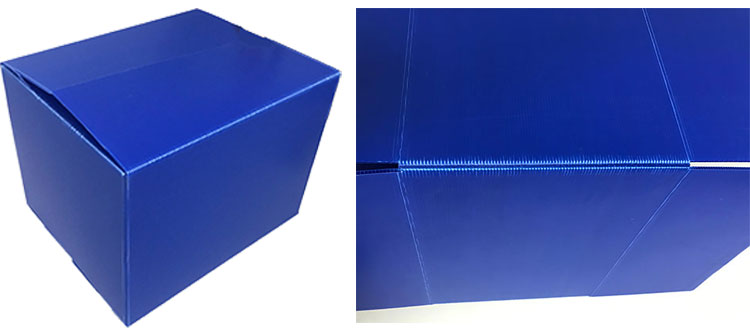

When the ultrasonic wave acts on the thermoplastic contact surface, it will generate tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area through the upper weldment. Since the welding area is two, The acoustic resistance at the welding interface is high, so local high temperature will be generated. And because of the poor thermal conductivity of the plastic, it cannot be dissipated in time for a while, and it gathers in the welding area, causing the contact surface of the two plastics to melt rapidly, and after a certain pressure is added, it is fused into one. When the ultrasonic wave stops working, let the pressure continue for a few seconds to make it solidify and form, thus forming a strong molecular chain to achieve the purpose of welding. It is characterized by firmness and good stability. Polyflute fluted polypropylene sheet manufacturers have 8 sets of ultrasonic welding equipment.

The characteristic is that there is no trace on the surface, and the conjoined body is firm. Corrugated plastic products made with seamless welding technology have a smoother appearance and are suitable for boutique production. It is conceivable that the cost is relatively high! At present, very few companies in the world have this technology. The one with this technology is Polyflute pp corrugated sheet supplier from China.

Ordinary glue will not work at all. Be sure to use special polypropylene glue, which is a one-component synthetic resin composite glue with strong adhesion and stable performance. It is mainly used for PP corrugated bonding and large-area bonding of PP and other materials. The glue has a moderate viscosity, can be cured at room temperature, is easy to use, and can be glued, dispensed, or manually glued. After the glue is fully cured, it is transparent and soft, and plays the roles of bonding, positioning, sealing, and waterproofing. Recommend 2 models for everyone:

1) Tecbond 267 high performance adhesive specially formulated for polyolefin plastics such as polypropylene and polyethylene. This adhesive has good resistance to high heat and low temperature.

2) Ad Tech 189-800 hot melt adhesive is the first choice for corrugated plastics such as PP and PE. With an open time of 25 seconds and a cure time of 5 seconds, it is ideal for plastic applications. It is also not dependent on moisture or humidity and has excellent pot life.

As one of the top 5 correx box suppliers in China, Polyflute has developed rapidly in recent years. Custom corrugated plastic sheets, pp corrugated boxes, coroplast signs are popular in Europe, America, Middle East, Australia, etc. Polyflute provides one-stop customized coroplast manufacturing service, customers can fully customize the specifications, sizes, colors and other details of coroplast sheets according to their specific needs.

For more information, please click: https://polyflute.com/

WhatsApp: +86-150-62936841

Email: Sophia@polyflute.com