Description

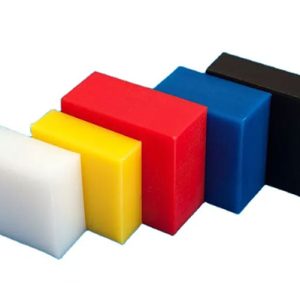

What are HDPE Plastic Sheets?

HDPE Plastic Sheets are almost completely waterproof, though it will allow oxygen, carbon dioxide and flavorings to pass through it. It can be clear (transparent), translucent or opaque, which makes it useful for a variety of functions. PE sheet is usually sold in rolls (though it sometimes comes in boxes of cut sheets) and different additives can be added to vary its functionality, for example making it fire retardant, UV inhibiting (if it’s to be used outdoors), anti-static (good for use on printed circuit boards), high strength and high or low slip. It can also be made from virgin grade, BRC approved food grade or recycled polythene, or can even contain a volatile corrosive inhibitor to minimize the formation of rust on the item it is covering.

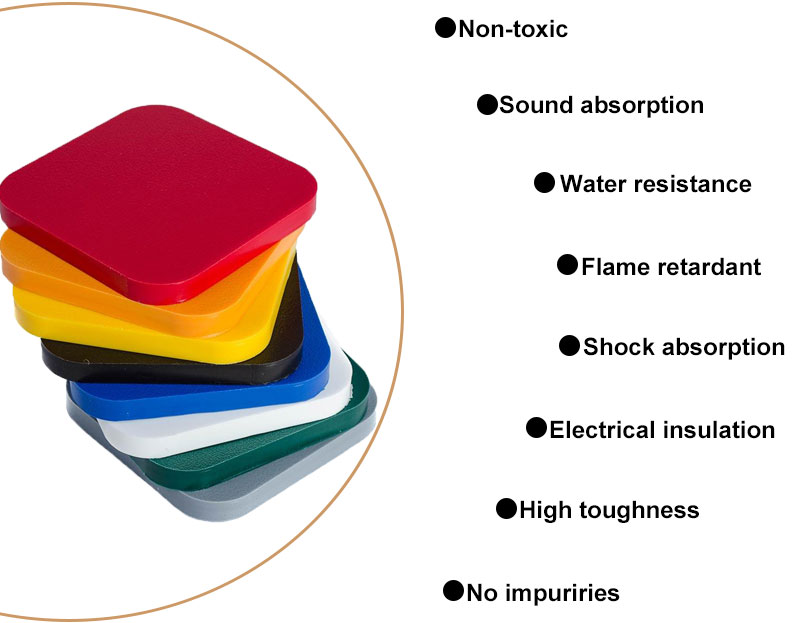

Features of HDPE Plastic Sheet

- Chemically Stable: HDPE plastic sheets have the properties of acid and alkali resistance, it is resistant to most chemicals for daily use and industrial.

- Low Temp Resistance: Unlike most plastics, polyethylene sheet has the characteristics of low temperature resistance, even at minus 40 degrees, it can maintain toughness without brittleness.

- Recycling: HDPE board is 100% recyclable. After the used polyethylene material is fragmented and heated to the melting point, it can be recycled, sorted and reused.

- Anti-abrasive: HDPE panel can resist impact and friction well, and is also widely used in industrial applications, such as rails and guides in manufacturing facilities.

- Highly Processable: Due to its high machinability, HDPE plastic board can be processed using a variety of machining methods, such as cutting, welding, deep drawing, routing, riveting, milling, and hot and cold forming.