Description

Introduction of the PP fluteboard

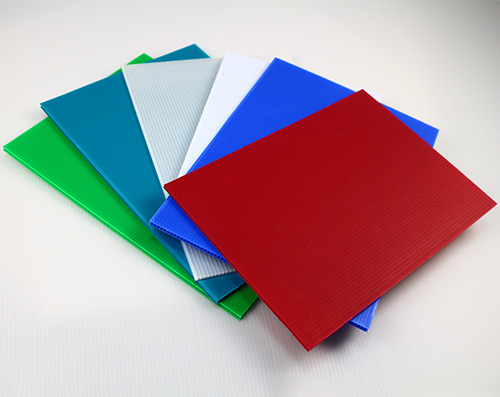

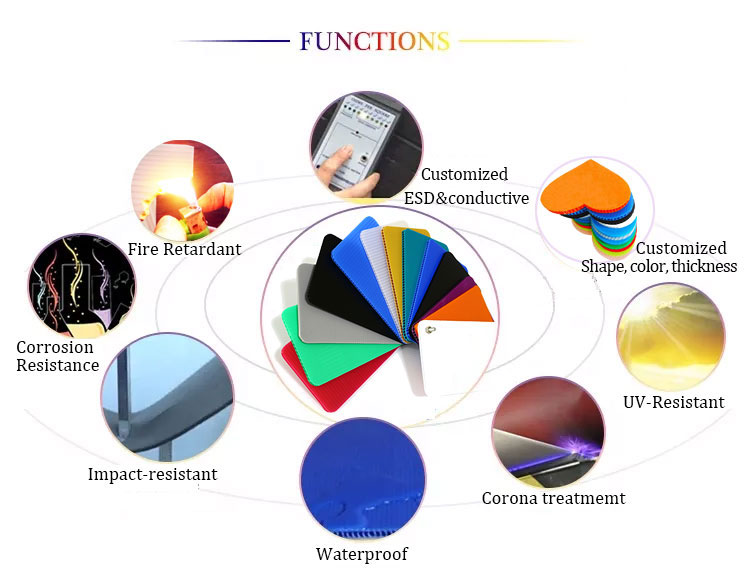

PP Fluteboard– also known under the trade names of Coroplast, Corflute, Correx, Corex, CartonPlast, Corrugated plastic sheet, Impraboard, Corriboard, IntePro, Proplex, Polyflute, Danpla, Twinplast or Corriflute – refers to a wide range of extruded twin wall plastic-sheet products produced from high-impact polypropylene resin specifically for use in the screen printing, display and packaging markets. Special products that require additives include: corona treatment, ultraviolet protection, anti-static, conductive, flame retardant, custom colors, corrosive inhibitors, among others.

Parameters:

|

Product Name

|

pp Fluteboard/Fluted Plastic Sheets |

|

Size

|

Customized

|

|

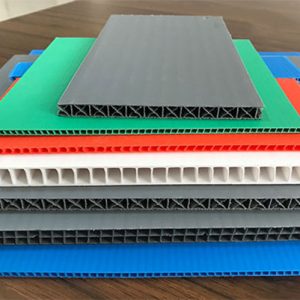

Thickness

|

2mm-12mm, or customized

|

|

Color

|

White, black, blue, grey, red, yellow, green, orange, customized

|

| Options | Common sheets, corona-treated sheets, anti-static/ESD sheets, fire-rated sheets, UV-resistant boards, etc |

|

Advantages

|

Strong and durable, lightweight, reusable, recyclable, cost-effective, customizable, etc

|

|

Application

|

Coroplast signs, floor protection, tree guards, tier sheets, fruits&vegetables packaging boxes, sneeze guards, wardrobe box, etc

|

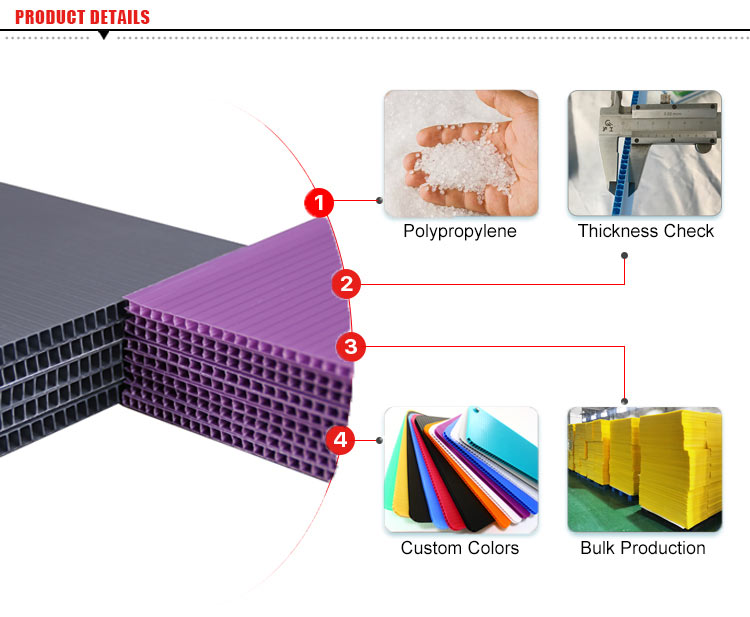

Fluted plastic sheets details:

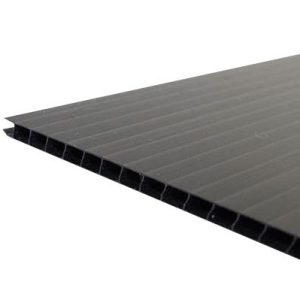

- Material: HDPP(100% new high density polypropylene raw materials)

- Technology: HDPP material(raw material +desiccant+ color master batch)→blender→extruding machine(Raw material melt pluralization)→mould(Forming extrusion)→Finalize the design→The first traction→Oven→cooler→The second traction→Shears→Stacked platform.

- Structure:

– Top and bottom plane board,

– The middle vertical stripes,

- Maximum width:2600mm

- Max length: According to customer’s request

- Thickness and weight:

| Thickness | 1.8mm | 2mm | 3mm | 4mm | 5mm | 6mm | 7mm | 8mm | 9mm | 10mm | 11mm | 12mm |

| weight | 350g | 400g | 450g | 650g | 850g | 1000g | 1400g | 1800g | 2000g | 2400g | 2600g | 2800g |

| The weight of PP fluteboard can accord customer’s requirement. | ||||||||||||

- Inspection equipment:

– Alcohol lamp, gauge, anti-statictester

– ECT/FCT has grown strength tester

– Tensile tester

– Hollow board special fixture fusion peel strength.

– Special fixture material 3 point bending

– High precision analytical balance

– The melt index tester

Advantages of the pp fluteboard:

- Light weight.

- Strong and durable.

- Impact resistant. Hygienic.

- Water-resistant.

- Non-toxic and resistant to chemicals.

- Cost-effective.

- Easy to convert.

- 100% Recyclable.

- Available in recycle grade.

- Available in flame retardant version.

- Contact us now!