Description

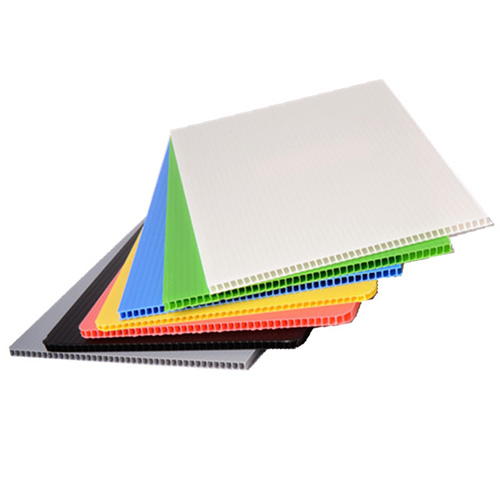

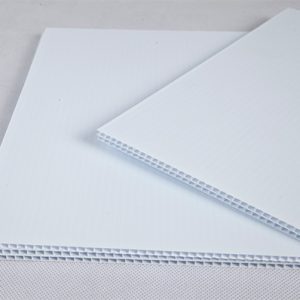

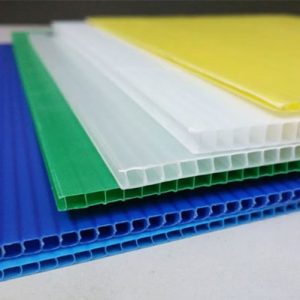

Anti-UV corex sheeting is also can be called UV-resistant PP corrugated/corflute/coroplast sheet. “UV” is the abbreviation for ultraviolet rays, and anti-UV means resisting the sun’s ultraviolet rays. The most significant feature of the UV-resistant pp hollow board is that it can effectively resist the damage of ultraviolet rays to the board itself. Its raw material is polypropylene. Adding an appropriate proportion of anti-UV particles in the production process can have the function of anti-ultraviolet rays. It is popular. On the one hand, it has the characteristics of light weight, moisture-proof, waterproof, corrosion-resistant and abrasion-resistant. On the other hand, it can be used outdoors and will not deform, break, or fade after long-term use.

Parameters:

|

Product Name

|

Anti-UV Corex Sheeting

|

|

Size

|

Standard: 1220mmx2440mm Or Customize(Width< 2600mm)

|

|

Thickness

|

2 mm-12 mm

|

|

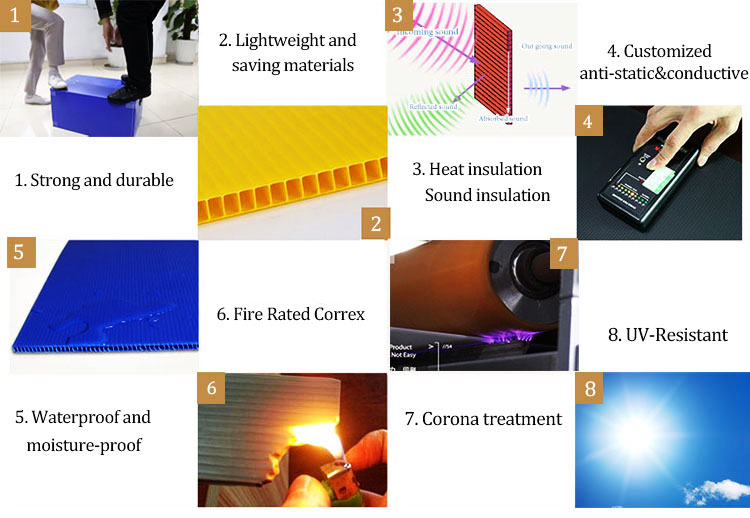

Advantages

|

Anti-UV, Eco-friendly, lightweight, strong and durable, waterproof, shockproof, cost-effective, customizable, etc

|

|

Applications

|

Electronics, integrated circuit packaging, electromagnetic wave shielding and other fields

|

|

Sample

|

Free

|

|

Packing

|

Film ordinary packing or as your request

|

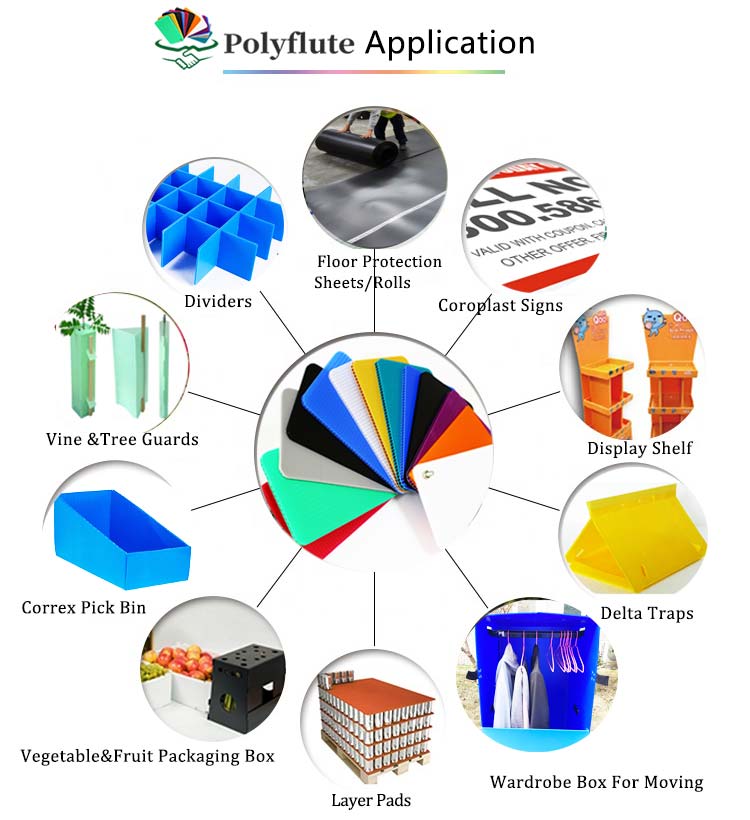

Applications of corex sheeting:

- Hardware industry – Due to the irregular shape and size of hardware parts, people can use the corex sheeting to customize hardware packaging boxes.

- Medical industry – We often see hospitals use trays made of correx sheets to classify and place different medicines to facilitate dispensing of medicines to patients.

- Maternal and infant industry – The most common is the baby stroller. The corrugated plastic sheet is used as the back board, which is safe and light. Of course, some children’s toys often use hollow boards as accessories.

- Express industry – This industry needs to frequently turn over different products. The characteristics of the corrugated plastic panel, such as durability, lightness and recycling, just meet the needs of the industry, and gradually replace the traditional carton. So the correx logistics box came out.

- Household industry – Correx boards can be used to make household storage boxes and wardrobes, which solves the problem of rationally arranging space for families.

- Food industry – In the food industry, the most difficult to transport is brittle glass canned food. The coroplast panel can be directly used for the layer pad, which successfully prevents the collision between the products.

- Other industries.