Description

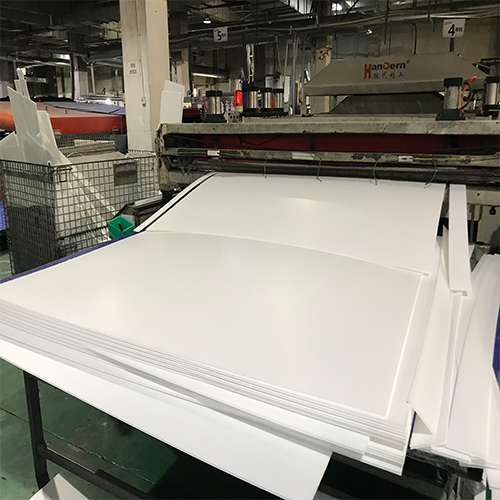

White corrugated plastic sheet

Corrugated plastic sheets have wide application in a variety of industries due to its various advantages. It is often used to make coroplast signs, pp floor protection sheets, pp layer pads, corrugated plastic boxes.

The raw material of corrugated plastic sheets is eco-friendly pp. Polypropylene is widely used in various fields, such as food packaging, billboards, etc., due to its high strength, good stiffness, and low cost. Polycarbonate is commonly used in electronic product casings, optical guides, etc. due to its good transparency, high strength, and flame retardancy.

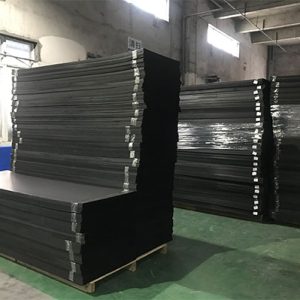

The size and thickness of the hollow board can be customized according to specific needs. Common sizes include 1220mm2440mm, 1250mm3050mm, 1500mm3050mm, 2000mm3050mm, etc.

Hollow panels with different thicknesses have different weight ranges, for example, the conventional weight of 4mm plastic hollow panels is 700 grams per square meter,These parameters will affect the load-bearing capacity and usage scenarios of hollow panels.

The production process of hollow boards includes steps such as melt mixing, extrusion molding, and post-treatment. Melting mixing is the process of adding the mixed raw materials to an extruder for heating and melting;

The produced hollow board needs to undergo physical performance testing and quality sampling testing to ensure that it meets relevant standards and customer requirements. Physical performance testing includes tensile strength, bending strength, impact toughness, etc.

Parameters of Polyflute PP flute sheet:

|

Product Name

|

Corrugated plastic sheets/Coroplast panels/Correx boards |

|

Size

|

Customized

|

|

Thickness

|

2mm-12mm, or customized

|

|

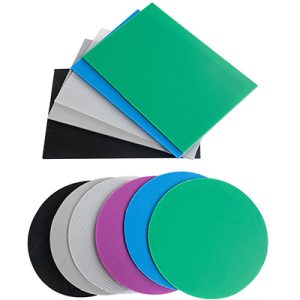

Color

|

White, blue, grey, black, red, yellow, green, orange, customized

|

| Options | Common sheets, corona-treated sheets, anti-static sheets, fire-rated sheets, UV-resistant sheets, etc |

|

Advantages

|

Customizable, strong and durable, lightweight, reusable, recyclable, cost-effective, etc

|

|

Application

|

Coroplast signs, floor covering, tree protectors, tier sheets, fruits&vegetables packaging boxes, wardrobe box, etc

|

If you need it, please contact us. We welcome your inquiry and will reply to you within 2 hours.