Description

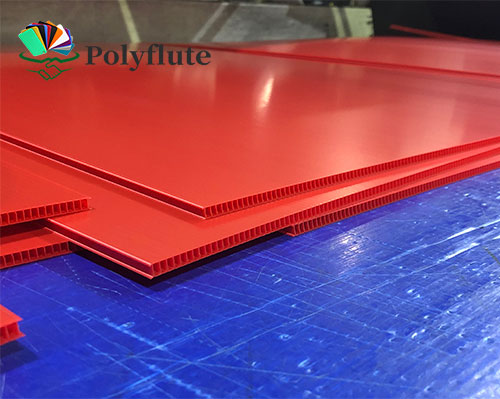

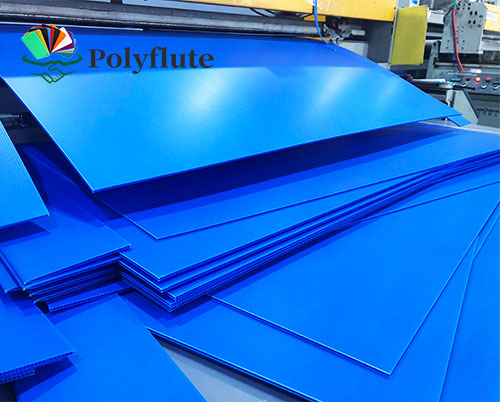

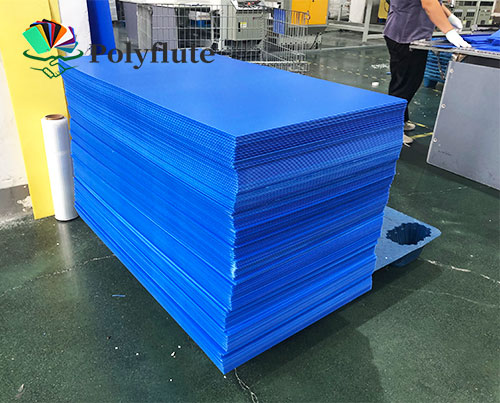

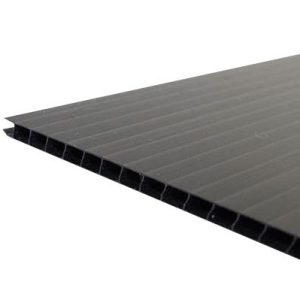

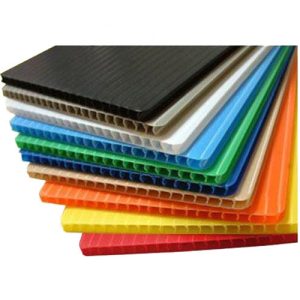

4×8 coroplast sheets are hollow lattice sheets made of polypropylene, which are lightweight, non-toxic, non-polluting, waterproof, shockproof, anti-aging, corrosion-resistant, and rich in color. Compared with cardboard structural products, coroplast boards have the advantages of moisture resistance and corrosion resistance. corrugated plastic sheet 4×8 is a common size, measuring 4 feet by 8 feet. 4×8 coroplast sheets are widely used in electronics, packaging, machinery, light industry, food, home appliances, and other industries.

Coroplast is also known as Corrugated Plastic, Corflute, Correx, PP Hollow, Polyflute, Danpla, etc.

Parameters of Polyflute PP flute sheet:

|

Product Name

|

Corrugated plastic sheets/Coroplast panels/Correx boards |

|

Size

|

Customized

|

|

Thickness

|

2mm-12mm, or customized

|

|

Color

|

White, blue, grey, black, red, yellow, green, orange, customized

|

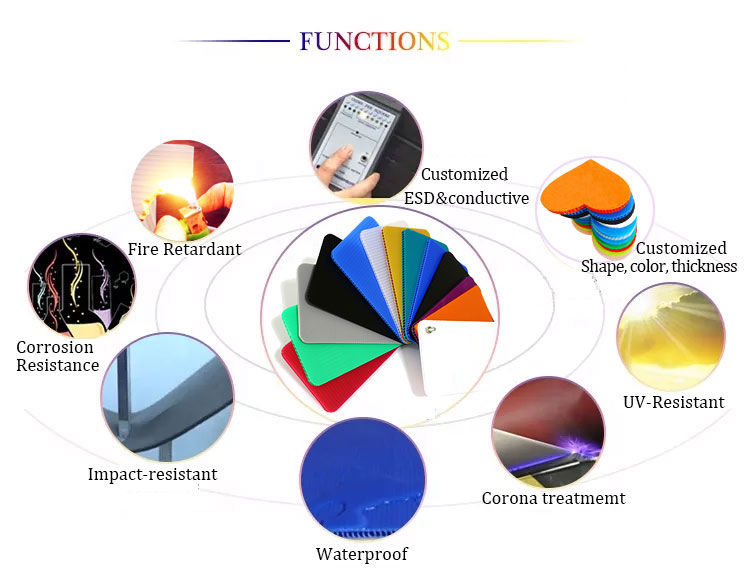

| Options | Common sheets, corona-treated sheets, anti-static sheets, fire-rated sheets, UV-resistant sheets, etc |

|

Advantages

|

Customizable, strong and durable, lightweight, reusable, recyclable, cost-effective, etc

|

|

Application

|

Coroplast signs, floor covering, tree protectors, tier sheets, fruits&vegetables packaging boxes, wardrobe box, etc

|

Our coroplast board has the following advantages:

- Waterproof and moisture-proof: It is made of high molecular polymer, which can effectively block moisture, ensure that the pp hollow board remains dry in a humid environment, and reduce the risk of moisture damage to the cargo.

- Anti-static: The special anti-static design can resist electromagnetic interference, protect sensitive electronic components, and avoid product quality problems caused by static electricity.

- Flame retardant: correx white sheets are made of flame retardant materials, even if they encounter a fire source, they can be extinguished automatically, improving the fire protection level of safe storage and transportation of goods.

- Lightweight and durable: Polyflute sheets are lightweight, have a long service life, are hard and not easy to deform, and are durable.

- Customer customization: We support customers’ personalized customization needs, such as size, color, etc., to optimize customer experience.

How to ensure the quality and durability of 4×8 coroplast sheets?

The quality of Corrugated plastic sheets depends on the manufacturer’s standards and raw material quality standards. Polyflute Corrugated Plastic Supplier can formulate corresponding quality requirements according to PP corrugated sheets with different characteristics. We will require the production department to strictly comply with this standard for production and manufacturing. In addition, when selecting materials, the intended use of the final product and environmental conditions need to be taken into consideration to ensure that the materials have sufficient strength and durability.