Polyflute® has launched plastic pallet divider sheets for the glass bottled product industry. This product replaces the existing cardboard layer pads on the market. Plastic separator sheets can also be used directly with corrugated plastic packaging boxes to provide complete packaging for various industries. These reusable layer pad pallet sheets can be customized to meet your exact requirements and are available in a variety of standard and FDA compliant colors. Custom printing can also be used to add logos or product specifications.

– Polyflute plastic pallet divider sheets will not absorb moisture that could breed bacteria and other contaminants. It is waterproof and does not soften like cardboard when wet.

– It will not rust, rot, mold or corrode like metal or wood. Plastic separator sheets can be cleaned and disinfected to provide product protection.

– These sustainable layer pad pallet sheets are made from 100% recyclable proprietary copolymer polypropylene. It’s a great way to protect your products and ecosystem.

– Provides a protective layer that reduces the risk of items being damaged in transit. They also protect the item when a cutter is used to open the package.

– Corrugated Plastic Pallet Dividers are extremely lightweight and durable. And the processing is also very simple, just need to directly cut a large piece of corrugated plastic board according to the required size.

– you can choose any color you like. But commonly used colors like blue, black, white and green are cheaper. Custom colors will be more expensive. Among them, Blue Corrugated Plastic Cardboard Layer Pads are our most produced.

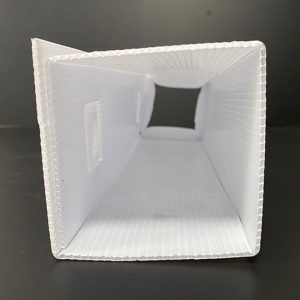

– Edge sealed plastic pallet divider sheets are more hygienic. It prevents bacteria from growing in crevices. If you have high hygiene requirements, you must choose plastic separator sheets for edge sealing.

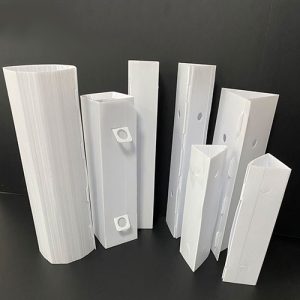

– For valuable or fragile items, in order to make the product more secure during transportation, general brands will choose layer pad pallet sheets with holes. It is also very easy to operate, simply snap the product into the hole of the right size.

– We usually refer to these tier sheets as corrugated plastic trays. This design is generally based on folding, which is convenient for export and saves freight. When not in use, it can be unfolded into a flat panel for easy storage. It also prevents the product from falling and accidentally injuring those around you.

– it prevents sewage from flowing into the laminate through the lattice holes, where bacteria can easily grow and attract cockroaches. So the edge-sealed tier sheets are more hygienic. Especially suitable for use in the beverage industry.

– If you are on a budget or your product is not food related, you can choose to use these unsealed layer pads for packaging. This kind of layer pads has the lowest cost. You can directly cut PP corrugated sheets according to customer requirements.

– Rounded corners are softer and protect flexible packaged products, so they don’t break them and prevent sharp corners from hurting movers. However, it is more labor-intensive than right-angle plastic separator sheets.

We believe that only high quality products and excellent service can bring us a lasting business. After more than ten years of development, we have formed a mature quality control system from raw materials to finished products.

All of our raw materials come from fixed suppliers, and we check the materials provided to us by our suppliers every time. In addition, all our products are certified by SGS and ISO9001, you can rest assured of the quality of our products.

If you need plastic pallet divider sheets or other customized plastic corrugated products, please feel free to contact us. You can fill out the form below, or email us and we will get back to you as soon as possible!