Corrugated plastic sheets have become a staple material across a broad spectrum of industries, thanks to their lightweight, durable, and versatile nature. From packaging and signage to agriculture and construction, these sheets offer an affordable and adaptable solution for both everyday and specialized applications. In this in-depth article, we explore what is corrugated plastic sheet used for, covering their primary functions, niche uses, and the reasons behind their widespread adoption.

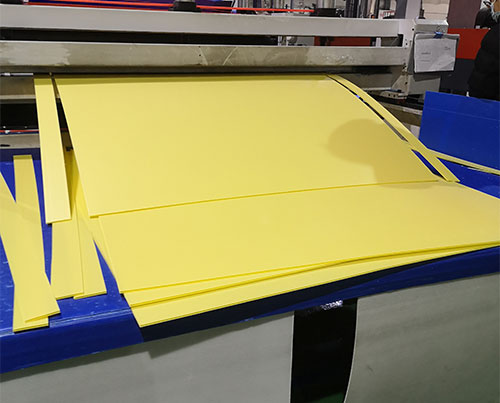

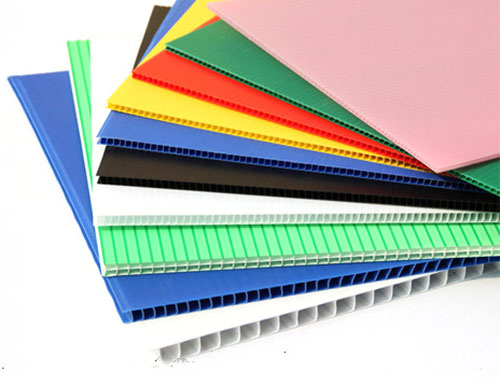

Before delving into specific applications, it’s essential to understand what corrugated plastic sheets are. Sometimes referred to by brand names like Corflute, Coroplast, or Twinwall plastic, these sheets are made from polypropylene or polyethylene. They consist of a twin-wall structure, which gives them strength and rigidity while keeping them lightweight.

Key properties of corrugated plastic sheets include:

These characteristics make them suitable for a wide range of uses across industries like packaging, advertising, agriculture, construction, logistics, and more.

Corrugated plastic sheets are widely used to create reusable shipping and storage boxes. Unlike cardboard, corrugated plastic boxes are water-resistant, making them ideal for damp, humid, or industrial environments where moisture exposure could damage traditional packaging materials. This water resistance helps ensure the integrity of the contents during transportation and storage, even in challenging conditions.

Benefits:

Additionally, corrugated plastic boxes are lightweight, which reduces shipping costs, and their rigid structure provides excellent stacking strength, allowing for efficient use of warehouse space.

In warehouse operations, corrugated plastic is often used to fabricate picking bins, stacking trays, and shelf dividers, playing a vital role in inventory management and order fulfillment.

Use cases:

These bins are especially common in automotive, electronics, and distribution centers where clear organization and easy visibility of components are critical to maintaining productivity and reducing errors during the picking process. Their durability allows them to withstand repeated use without degrading, supporting long-term operational efficiency.

Corrugated plastic sheets are a popular choice for indoor and outdoor signage due to their printable surface and weather-resistant properties.

Realtors frequently use corrugated plastic signs to advertise properties. The signs are lightweight, easy to install on stakes, and cost-effective.

Temporary signage for marathons, festivals, trade shows, and community events often use corrugated plastic because:

Retailers use corrugated plastic sheets for point-of-purchase (POP) displays, window signs, and product promotions. Their low cost and easy customization make them ideal for short-term marketing campaigns.

During construction or renovation, floors can be shielded using corrugated plastic floor protection sheets. They protect against:

Contractors favor corrugated plastic over cardboard because it resists moisture and doesn’t tear easily.

Corrugated plastic sheets can be taped to walls, doors, and windows to prevent dust, debris, and scratches during remodeling.

In some applications, corrugated plastic sheets serve as a lightweight form for pouring small concrete structures, especially where reusability is important.

In farming and landscaping, corrugated plastic is often used to create tree guards and plant protectors that shield young plants from animals, wind, and sun.

Their moisture resistance and ability to diffuse light make corrugated plastic sheets suitable for greenhouse walls, seedling trays, and partitions.

Corrugated plastic trays can be used for hydroponic setups and seed germination due to their ease of cleaning and inert nature.

In logistics and manufacturing, corrugated plastic sheets are cut into layer pads or dividers to separate and protect products during transit. These are especially useful in:

Using die-cutting or CNC methods, manufacturers create custom inserts from corrugated plastic to fit inside cases, crates, or cartons, providing tailored protection.

Students and teachers use corrugated plastic boards for science fairs, craft projects, and visual displays. They offer a sturdier alternative to poster board and are easy to decorate.

Makers and hobbyists love corrugated plastic for:

Lightweight, solid-colored sheets are sometimes used as backdrops in photography studios or video production for cost-effective set design.

In automotive and aerospace industries, corrugated plastic sheets are used for:

These sheets are often used because they are chemically inert and resistant to oils and industrial solvents.

Retail stores use corrugated plastic as shelf liners, product display platforms, and temporary spacers. The sheets can be custom printed or die-cut to suit various formats.

During the pandemic, corrugated plastic sheets were quickly repurposed into sneeze guards, partition walls, and temporary barriers in public spaces.

Campers use corrugated plastic sheets for ground mats, tent flooring, or even makeshift wind barriers. Their durability and water resistance are perfect for outdoor conditions.

Corrugated plastic is commonly used in the construction of hobbyist remote-control airplanes due to its light weight and high strength-to-weight ratio.

Though made from plastic, corrugated sheets offer sustainability advantages:

They also reduce waste in packaging and signage by lasting longer and being more resilient than paper-based alternatives.

When selecting corrugated plastic sheets, consider the following:

Corrugated plastic sheets can be easily customized using:

This makes them ideal for branding, labeling, and tailored fit within packaging systems.

To better visualize the versatility of corrugated plastic sheets, here is a comprehensive summary of the key applications across different industries, along with the specific benefits they offer in each scenario. This table provides a snapshot of how these multifunctional sheets meet the practical demands of professionals from construction workers to creative artists.

| Industry/Application | Use Cases | Key Benefits |

|---|---|---|

| Packaging & Logistics | Reusable boxes, layer pads, tote bins | Durable, moisture-resistant, cost-effective |

| Signage & Advertising | Real estate signs, event boards, retail promotions | Printable, weatherproof, lightweight |

| Construction | Floor protection, surface shielding, concrete formwork | Impact-resistant, easy to install, reusable |

| Agriculture & Horticulture | Plant guards, greenhouse partitions, hydroponic trays | UV-resistant, water-resistant, customizable |

| Education & DIY | School displays, model building, robotics competitions | Safe, easy to cut, excellent for prototyping |

| Retail & Commercial | Shelf liners, temporary displays, COVID barriers | Clean look, easy to replace, hygienic |

| Automotive & Industrial | Part dividers, in-process material trays, assembly line barriers | Oil/chemical resistant, strong yet lightweight |

| Recreational & Outdoor | Tent flooring, RC aircraft frames, camping mats | Portable, waterproof, high strength-to-weight ratio |

As the table shows, corrugated plastic sheets are not limited to one function or sector. Their lightweight structure paired with strength and environmental resistance makes them adaptable for temporary or long-term usage. Moreover, the ability to customize these sheets through cutting, printing, and forming allows businesses and individuals to meet unique requirements efficiently. Whether for protective purposes, promotional needs, or structural support, corrugated plastic continues to prove itself as an essential modern material.

To summarize, corrugated plastic sheets are incredibly versatile and are used in numerous sectors including packaging, signage, construction, agriculture, education, and industry. Their strength, adaptability, and resistance to water and chemicals make them a smart choice for both short-term and long-term applications.

Whether you’re running a warehouse, managing a construction site, or creating a school display, corrugated plastic sheets offer the durability and customization you need—without compromising on cost-efficiency.

As industries continue to seek sustainable, lightweight, and adaptable materials, the use of corrugated plastic sheets is only expected to grow.

If you’re looking for durable, versatile, and high-quality corrugated plastic sheets, PolyFlute is your trusted partner. With a wide range of customizable solutions ideal for packaging, signage, construction, and more, PolyFlute helps businesses optimize operations and reduce costs.

Don’t wait—contact PolyFlute today to discuss your specific needs, request samples, or get a personalized quote. Let PolyFlute provide you with the perfect corrugated plastic products tailored to your industry. Reach out now and experience the difference!