In the fast-paced world of warehousing and logistics, efficiency is king. To meet the demands of rapid order fulfillment and inventory management, businesses must optimize every aspect of their warehouse operations. One essential tool that has gained widespread adoption is large warehouse picking bins. These bins are specially designed to streamline the picking process, improve space utilization, and reduce handling errors. Unlike traditional cardboard boxes or improvised containers, large warehouse picking bins are durable, reusable, and customizable to suit a wide variety of products and environments.

From small parts in e-commerce fulfillment centers to bulky items in industrial warehouses, these bins help workers quickly locate and transport items, boosting productivity and accuracy. Moreover, with the rise of automated warehouses and smart inventory systems, these bins are increasingly integrated into high-tech workflows, supporting barcode scanning, RFID tagging, and robotic picking. This comprehensive guide explores the many benefits, types, applications, and best practices for using large warehouse picking bins to elevate your warehouse operations to the next level.

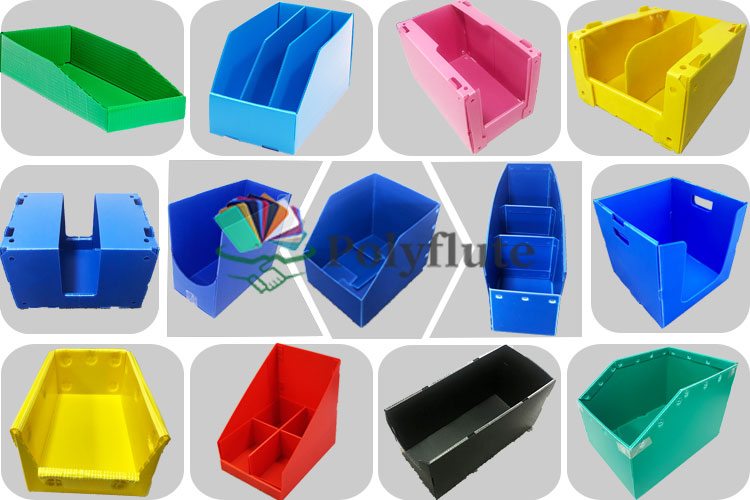

Large warehouse picking bins are containers designed specifically for storing and organizing inventory in warehouses, making the picking process faster and more efficient. They come in a variety of materials, sizes, and configurations to accommodate different product types and operational needs. Typically made from durable plastics, these bins resist wear and tear, moisture, and chemical exposure, which are common in warehouse environments. Their robust construction ensures they can be stacked securely and handled repeatedly without damage.

Many bins feature ergonomic designs with built-in handles, reinforced edges, and lids to protect contents from dust or spills. In addition, some models come with color coding or labeling areas to enhance inventory identification. By standardizing storage with picking bins, warehouses can reduce clutter, minimize product damage, and speed up picking accuracy. These bins serve as the backbone for organized inventory flow, ensuring that workers spend less time searching for items and more time fulfilling orders efficiently. Whether in manual picking or automated systems, large warehouse picking bins enable smooth material handling and contribute to overall operational excellence.

There are several types of large warehouse picking bins, each designed for specific functions or product categories. The most common types include:

Each type serves unique purposes and can be selected based on product dimensions, fragility, picking method, and storage conditions. For example, electronics manufacturers may prefer lidded bins to avoid dust, while food distribution centers might use open front bins for rapid access. Understanding these differences helps warehouses tailor their bin inventory to optimize workflow and protect stored goods.

| Bin Type | Features | Ideal Use Case |

|---|---|---|

| Stackable | Secure stacking, space-saving | General storage, bulk items |

| Lidded | Dust protection, secure closure | Electronics, pharmaceuticals |

| Open Front | Easy access, visibility | Fast picking, retail fulfillment |

| Divided | Compartments for small items | Small parts, hardware |

| Wire Mesh | Ventilation, visibility | Produce, large bulky items |

Material choice significantly impacts the durability and suitability of large warehouse picking bins. The most common materials include:

Plastic bins outperform cardboard or metal alternatives in terms of moisture resistance, reusability, and ease of cleaning. Polypropylene and HDPE bins are especially popular due to their balance of strength and cost-effectiveness. When selecting materials, warehouses consider the type of goods stored, environmental conditions, and handling frequency. For example, outdoor warehouses or cold storage facilities often opt for bins made of UV-resistant materials that won’t crack or warp under extreme temperatures.

Choosing the right colors for large warehouse picking bins is more than just an aesthetic decision—it plays a crucial role in improving warehouse organization, efficiency, and safety. Color coding has become a widely adopted practice in warehouses worldwide because it provides a simple yet powerful visual cue to help workers quickly identify bin contents, streamline workflows, and reduce picking errors.

In busy warehouse environments, speed and accuracy are vital. Color-coded bins allow warehouse staff to instantly recognize categories of goods or specific processes without needing to read detailed labels every time. For example, red bins might designate urgent orders or high-priority items, while blue bins could be reserved for finished goods ready for shipment. Green bins might be used for raw materials or returned products. This visual differentiation minimizes the risk of confusion and mistakes, ultimately boosting picking accuracy and order fulfillment rates.

Color coding also supports better inventory management and stock rotation. By assigning different colors to batches based on arrival dates or expiration dates (especially important in food and pharmaceutical industries), warehouses can ensure that products are used in the correct sequence, reducing waste and spoilage.

The most common colors available for large warehouse picking bins include:

Many manufacturers also offer custom colors to match company branding or specific organizational needs, enabling warehouses to design an intuitive, easy-to-follow system tailored to their operations.

Color coding in picking bins not only enhances productivity but also improves safety. For instance, using bright or fluorescent colors for bins containing hazardous materials helps workers quickly recognize and handle those items with caution. Similarly, color-coded bins can guide staff in sorting and segregating items that require different storage conditions, such as refrigerated versus room temperature goods.

In large warehouses where multiple shifts work around the clock, consistent use of color-coded bins helps maintain operational continuity and reduces training time for new employees by simplifying the learning process.

While colors provide immediate visual guidance, combining color coding with clear labels and barcodes offers the most robust solution. This layered approach ensures that even in complex warehouse environments, workers have multiple ways to confirm the correct bin and its contents, minimizing errors and enhancing traceability.

Large warehouse picking bins offer multiple advantages that help improve warehouse efficiency and reduce operational costs:

By investing in the right picking bins, warehouses not only streamline workflows but also create a safer, more ergonomic environment for workers.

Large warehouse picking bins come in a wide range of sizes to fit diverse inventory needs. Standard sizes often start from small bins approximately 12x8x6 inches to large bins measuring up to 48x40x18 inches or more. The size chosen depends on the volume, shape, and weight of the products being stored.

| Size (inches) | Typical Use |

|---|---|

| 12 x 8 x 6 | Small parts, hardware, fasteners |

| 16 x 12 x 10 | Medium-sized items, packaged goods |

| 24 x 16 x 12 | Bulkier products, automotive parts |

| 36 x 24 x 18 | Heavy or large items |

| 48 x 40 x 18 | Palletized large goods, bulk storage |

Bins can also be configured with features such as:

Choosing the right size and configuration ensures bins are ergonomically manageable and optimize warehouse space utilization.

Large warehouse picking bins are used across multiple industries due to their versatility:

| Industry | Application Example |

|---|---|

| Food and Beverage | Storing packaged foods, beverage bottles, and fresh produce with airflow bins |

| Pharmaceuticals | Transporting and storing medicines with hygienic, lidded bins |

| Electronics | Organizing fragile components in anti-static bins |

| Manufacturing | Holding raw materials and finished goods for assembly lines |

| Retail and E-commerce | Fast order picking and packing with color-coded bins |

These bins enable safe, efficient handling of goods, protect product integrity, and facilitate faster order fulfillment cycles.

To maximize the benefits of large warehouse picking bins, warehouses should adopt the following best practices:

Following these practices ensures picking bins contribute effectively to warehouse productivity and product safety.

Q1: Can large warehouse picking bins be customized?

Yes, many manufacturers offer custom sizes, colors, and features such as lids or dividers to suit your specific inventory needs.

Q2: Are plastic picking bins recyclable?

Most bins are made from recyclable plastics like polypropylene and HDPE, allowing them to be recycled at the end of their lifespan.

Q3: How do large picking bins improve warehouse safety?

By organizing inventory and reducing clutter, they minimize trip hazards and ensure ergonomic handling, which reduces workplace injuries.

Q4: Can these bins be used with automated picking systems?

Absolutely. Many large warehouse picking bins are designed to integrate with conveyors, robotic arms, and scanning devices, facilitating automation.

Q5: What is the typical lifespan of plastic picking bins?

With proper use and maintenance, plastic picking bins can last several years, often outperforming cardboard or metal alternatives in durability.

Efficient warehouse operations depend heavily on smart storage and picking solutions. Large warehouse picking bins are an indispensable asset for organizing inventory, speeding up order fulfillment, and protecting goods from damage. Their versatility, durability, and adaptability to modern warehouse technologies make them a must-have for businesses seeking to optimize their supply chain processes. Whether you operate in food distribution, manufacturing, pharmaceuticals, or e-commerce, choosing the right picking bins tailored to your specific needs will deliver tangible benefits.

For high-quality large warehouse picking bins and durable corrugated plastic sheets, trust Polyflute, a leading manufacturer committed to providing innovative and reliable storage solutions tailored for modern warehouses. Contact us today to explore how we can help improve your warehouse efficiency with our products.