Malaysia’s industrial ecosystem is rapidly evolving, driven by urban expansion, manufacturing growth, and sustainability goals. Within this landscape, plastic materials are playing an increasingly important role. Corrugated plastic sheets—lightweight, waterproof, and reusable—have found utility in nearly every major sector. These include agriculture, logistics, advertising, construction, and even healthcare. The search for a dependable corrugated plastic sheets supplier in Malaysia is no longer lim…

In addition, Malaysia’s regional trade agreements and export infrastructure make it a strategic hub for supply and distribution. The growing preference for corrugated plastic sheets over traditional paperboard or metal options also reflects changing consumer and business priorities. Durability, recyclability, and long-term cost-efficiency are now major decision factors.

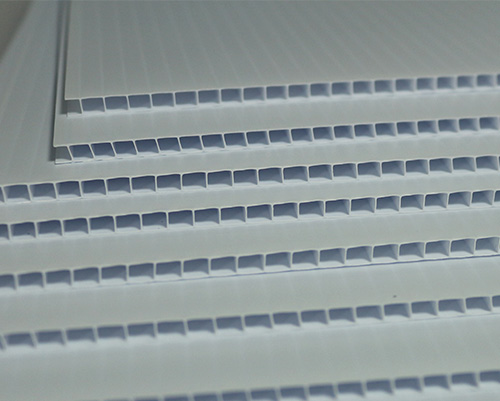

Corrugated plastic sheets are often made from polypropylene (PP) and feature a fluted structure sandwiched between two flat plastic layers. This unique design offers remarkable strength-to-weight ratio, allowing it to outperform many other materials in similar applications.

Key physical and chemical properties:

The production of these sheets involves extrusion, where molten PP resin is shaped into a fluted sheet. Advanced machinery ensures uniform thickness, density, and dimensional stability. Leading PP corrugated sheet manufacturers in Malaysia use either virgin or recycled PP, depending on client needs.

Key Applications:

Because Malaysia is exposed to high humidity and tropical rain, the waterproof and rot-proof characteristics of plastic sheets offer clear advantages over traditional materials like paper or cardboard.

Choosing the right corrugated plastic sheets supplier in Malaysia requires consideration of several critical factors. Not all suppliers provide the same level of quality, service, or customization.

Suppliers offering virgin PP materials often have higher-quality sheets with better performance. However, if cost is a major concern and the application is short-term, recycled PP is acceptable.

Advanced PP corrugated sheet manufacturers in Malaysia typically have high-end extrusion and die-cutting machines, which ensure dimensional accuracy, consistent thickness, and smooth finishes.

Whether you need custom color-matched sheets, anti-static versions for electronics, or UV-stabilized sheets for outdoor use, flexibility in production is a hallmark of a good supplier.

A reliable supplier will have a well-organized inventory system and logistics network. Look for those offering secure packaging, efficient loading processes, and reliable lead times. Some even provide urgent delivery or consignment inventory for large clients.

Responsiveness, willingness to offer samples, and transparent communication can make a big difference, especially for long-term partnerships.

Choosing a local corrugated plastic sheets supplier in Malaysia also means easier factory visits and faster sample evaluation, giving your procurement team better control over product quality.

Malaysia’s domestic demand for corrugated plastic sheets is witnessing strong growth. Several macroeconomic and sector-specific factors are contributing to this trend.

As cities like Kuala Lumpur and Johor Bahru expand, the need for floor protection boards, signage boards, and wall shields in construction has surged. Contractors prefer plastic sheets over wood due to cost-efficiency and resistance to mold and water.

Malaysia’s focus on modernizing agriculture, particularly in regions like Perak and Sabah, has created a new market for corrugated plastic dividers, nursery trays, and plant bed linings.

Plastic crates and reusable boxes are replacing traditional cardboard in many warehouses and delivery centers. This shift is also driven by sustainability policies that reward reusable materials.

Event organizers require temporary and lightweight signage solutions. Corrugated plastic signs offer affordable, vibrant, and waterproof options that can be quickly installed and dismantled.

Educational institutions and municipal bodies are increasing procurement of corrugated plastic sheets for partitioning, signage, storage, and waste separation.

Local buyers value Malaysian suppliers for their quick turnaround, adherence to regional safety standards, and lower cost-to-performance ratios.

Not all suppliers are manufacturers. When choosing a PP corrugated sheet manufacturer in Malaysia, you’re better positioned to negotiate pricing, customize orders, and ensure quality.

Key features of a top-tier manufacturer:

Many Malaysian manufacturers export across Southeast Asia, Australia, and the Middle East. This is due to Malaysia’s strong plastic industry infrastructure and reliable labor force.

A notable name in this space is **Polyflute**, a professional corrugated plastic sheets manufacturer known for consistent quality, competitive pricing, and prompt support. Though we avoid brand-heavy discussions, it’s worth noting how companies like these set benchmarks for reliability and service.

For OEM clients, Malaysian manufacturers also offer white-labeling and barcode printing directly on the sheets. If you’re sourcing for resale or redistribution, this flexibility is invaluable.

When selecting materials for packaging, signage, construction, or industrial purposes, decision-makers in Malaysia often compare corrugated plastic sheets with other alternatives such as cardboard, plywood, and solid polypropylene boards. Understanding how corrugated plastic sheets supplier in Malaysia offerings compare against these materials can help businesses make informed decisions tailored to their specific use cases.

1. Water and Chemical Resistance

One of the key advantages of corrugated plastic is its resistance to water and chemical damage. Unlike cardboard, which quickly degrades when exposed to moisture, corrugated plastic remains structurally intact even in wet environments. This property alone makes it ideal for outdoor applications and for use in sectors such as agriculture, logistics, and marine packaging.

2. Lightweight Yet Durable

In terms of weight, corrugated plastic is significantly lighter than plywood while maintaining impressive durability. For instance, signage companies that previously relied on wooden boards are now shifting to corrugated plastic for easier transport, longer lifespan, and better printing adhesion. Additionally, it is 100% recyclable, which provides a distinct environmental advantage in a world increasingly focused on sustainable solutions.

3. Versatility and Customization

Another point of comparison is versatility. PP corrugated sheet manufacturer Malaysia suppliers often offer sheets in various thicknesses, densities, and colors, allowing users to fully customize products according to their design, safety, and branding requirements. Cardboard and plywood lack this level of customization and tend to degrade faster under stress or repeated use.

4. Comparative Table of Materials

| Property | Corrugated Plastic Sheets | Cardboard | Plywood | Solid PP Board |

|---|---|---|---|---|

| Water Resistance | Excellent | Poor | Moderate | Excellent |

| Weight | Very Light | Light | Heavy | Medium |

| Durability | High | Low | High | Very High |

| Customizability | High | Low | Low | Moderate |

| Environmental Friendliness | Recyclable & Reusable | Recyclable | Not Easily | Recyclable |

| Printability for Signage | Excellent | Good | Poor | Moderate |

| Cost Efficiency Over Time | High | Low | Moderate | Moderate |

| Ideal Use Cases | Signage, packaging, dividers | Boxes, crafts | Flooring, heavy-duty use | Engineering applications |

5. Market Trends and Supplier Advantages

This comparative analysis shows why many companies now prefer to work with a corrugated plastic sheets supplier in Malaysia who can provide reliable quality and diverse product options. While cardboard may still dominate low-cost, single-use packaging, industries requiring long-term durability and exposure resistance increasingly choose corrugated plastic.

Furthermore, when sourced from a specialized PP corrugated sheet manufacturer Malaysia, these sheets can even be tailored with anti-UV, flame retardant, or conductive properties, pushing their utility far beyond that of any traditional material.

The advantages of sourcing from a corrugated plastic sheets supplier in Malaysia go far beyond price. Here are the broader benefits:

Sourcing locally avoids expensive import duties, customs delays, and container shipping fees. For Southeast Asian buyers, it also means faster fulfillment.

More Malaysian manufacturers are adopting closed-loop production, where off-cuts and returned products are recycled back into new sheets. Some suppliers also use solar power and water recycling systems.

Need 500 blue, 3mm thick, anti-UV sheets with specific dimensions? A local PP corrugated sheet manufacturer in Malaysia can typically fulfill that within days instead of weeks.

As your business grows, working with a local supplier allows you to scale orders up or down easily. This is particularly useful for startups, SMEs, and fast-moving industries like logistics or event management.

Choosing local doesn’t just make economic sense—it also supports the growth of Malaysia’s manufacturing sector, encourages innovation, and helps meet national sustainability goals.

Ultimately, local sourcing from a Malaysian corrugated plastic sheets supplier offers agility, affordability, and accountability—all of which are invaluable in today’s unpredictable global markets.

Malaysia is rapidly establishing itself as a regional hub for high-quality corrugated plastic materials. With reliable infrastructure, skilled labor, and increasing attention to environmental responsibility, the country is well-positioned to meet the growing demand for corrugated plastic sheets.

For businesses looking to source from a dependable corrugated plastic sheets supplier in Malaysia, the opportunities are vast. From agriculture to construction and packaging to advertising, corrugated plastic is the smart material choice.

Whether you need bulk PP corrugated sheets or custom die-cut boxes, engaging with a trusted Malaysian supplier will save you time, reduce risk, and enhance your product offerings. Just as importantly, it will align your business with sustainable and cost-efficient practices that are defining the future of global trade.

In the long run, partnering with an experienced PP corrugated sheet manufacturer in Malaysia could be one of the best decisions for your supply chain strategy and product quality.