Corflute sheets, known for being lightweight, weather-resistant, and versatile, are widely used in construction, signage, and packaging industries. Made from polypropylene plastic, these corrugated plastic sheets provide an economical solution for temporary fencing, advertising displays, and protective packaging. While corflute sheets are affordable compared to many other materials, their price can vary significantly depending on several factors.

For buyers and procurement professionals, understanding what drives the price of corflute sheets is crucial to making cost-effective purchasing decisions. As a reliable supplier, Polyflute has extensive experience in manufacturing and delivering high-quality corflute sheets globally. In this article, we’ll explore the key factors that affect corflute sheet prices and provide practical insights to help you evaluate offers, optimize orders, and reduce your material costs without compromising on quality.

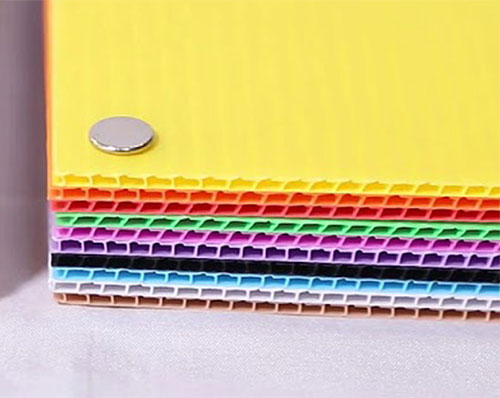

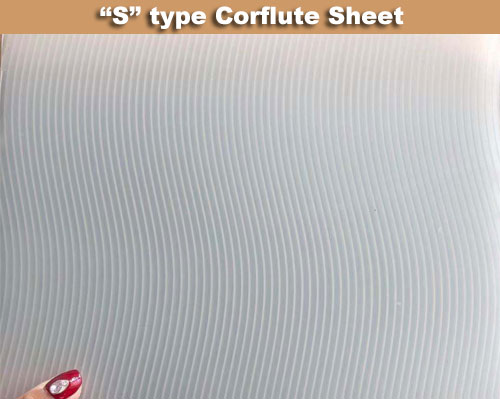

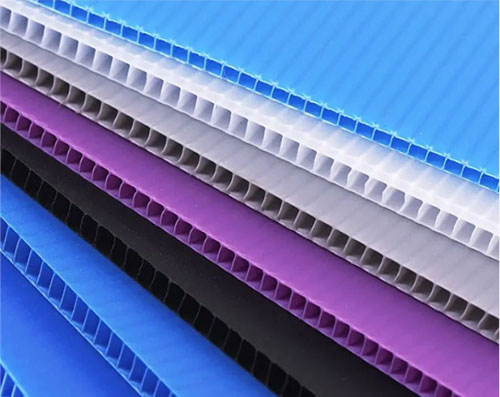

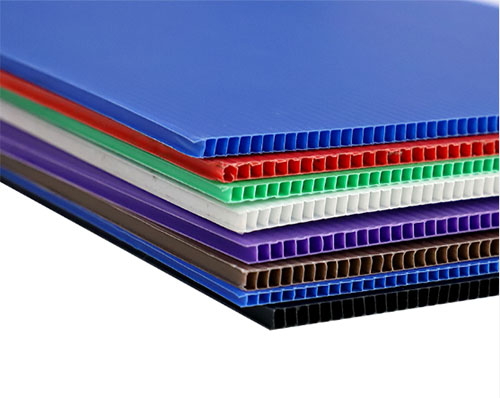

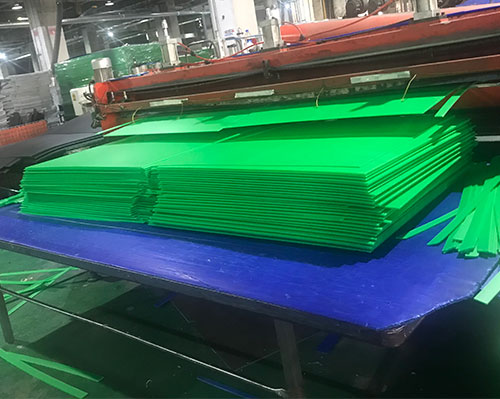

Corflute sheets, also known as corrugated plastic sheets or fluted polypropylene boards, are twin-wall extruded plastic sheets made from high-impact polypropylene resin. They are durable, lightweight, moisture-resistant, and chemically inert, making them suitable for both indoor and outdoor applications.

Because of their broad usability and the possibility for customization, the price of corflute sheets can vary based on size, thickness, treatment, and order volume.

The price of corflute sheets typically falls within a broad range depending on the product’s specifications, production techniques, and supply chain considerations. Understanding the typical price structure is essential for making smart procurement decisions, especially when dealing with large-scale applications in construction, advertising, or packaging.

One of the most significant price variables is order volume. As with many plastic-based materials, corflute sheet pricing benefits substantially from economies of scale. Bulk purchases often qualify for discounted rates, and full-container-load (FCL) orders can drastically reduce the unit cost, particularly when combined with optimized packaging and shipping.

At Polyflute, we recognize that different projects require different pricing models. That’s why we offer flexible, tiered pricing structures based on order size, customization level, and destination. This approach allows customers to strike the right balance between cost and performance—whether they’re buying a small batch for a limited campaign or stocking up for ongoing production needs.

By offering personalized quotes and volume discounts, Polyflute helps ensure that customers receive maximum value tailored to their specific application and budget.

The primary raw material in corflute sheets is polypropylene, a petroleum-based thermoplastic. The market price of polypropylene fluctuates with global oil prices and supply chain disruptions. When resin costs rise, so do the prices of finished sheets.

Polyflute sources high-grade polypropylene and maintains long-term supplier partnerships to stabilize cost without sacrificing quality.

Thicker and larger sheets require more material and longer production time, which increases costs. For example:

Standard sheets (usually white or black) are cheaper. Custom colors or printed designs (e.g., company logos or safety messages) require additional production steps:

Polyflute offers customizable options, but clearly communicates the cost differences upfront to help clients manage budgets.

Large orders usually qualify for tiered pricing. Bulk purchases reduce the per-unit cost as production and logistics become more efficient. A buyer ordering 10,000 square meters will pay significantly less per sheet compared to one ordering 200 square meters.

Polyflute provides special discounts for long-term and bulk customers, helping businesses lower operational costs.

Shipping costs are a major factor in total price—especially for international buyers. Corflute sheets, though lightweight, are bulky and require space-efficient logistics.

Polyflute has export-ready packaging and logistics solutions, including container optimization, to minimize freight costs per unit.

Corflute sheets manufactured under strict quality control and compliance with environmental or industry-specific standards (such as RoHS, REACH, or FDA) may be priced higher, but they offer long-term durability and safety.

Polyflute ensures ISO-compliant production, which justifies the value even if the upfront price is slightly higher than low-end alternatives.

Polyflute, as a specialized manufacturer of corrugated plastic sheets, understands the importance of delivering value alongside affordability. Here’s how the company achieves competitive pricing without compromising on quality:

Polyflute invests in automated extrusion lines, reducing waste and labor costs. This allows for consistent product quality and reduced production expenses.

By securing raw materials from trusted long-term partners, Polyflute avoids drastic price hikes caused by market instability.

With an experienced international logistics team, Polyflute can fulfill orders efficiently to regions including Australia, Southeast Asia, Europe, and the Middle East, reducing time and cost burdens for global buyers.

Whether you’re a signage company needing custom colors or a construction contractor looking for rugged UV-protected panels, Polyflute offers a range of customization options with transparent pricing to match your project scope.

The price of corflute sheets doesn’t exist in a vacuum—it is influenced by broader market trends and global economic factors. Buyers often overlook these external variables, but they can have a significant impact on procurement budgets and lead times.

Polypropylene, the primary material used in corflute sheets, is derived from crude oil. As such, fluctuations in global oil prices directly impact the cost of resin. Political instability, OPEC production changes, and natural disasters affecting refineries can all lead to price spikes.

The global logistics landscape has changed dramatically in recent years. Rising fuel costs, port congestion, and container shortages can significantly increase the landed cost of imported corflute sheets. For international buyers, even a modest rise in freight charges can make a noticeable difference in per-unit pricing.

For buyers importing from overseas suppliers, exchange rate movements between the US dollar, Euro, or local currencies can affect final purchase prices. A weakening local currency can make imports more expensive overnight, while a strong currency may open up cost-saving opportunities.

Tighter environmental policies in manufacturing regions—such as limits on plastic production, waste treatment regulations, or energy usage standards—can lead to increased compliance costs. These are often passed down the supply chain in the form of slightly higher prices for eco-compliant corflute sheets.

By staying informed on these macroeconomic trends, purchasers can better plan their buying cycles and take advantage of favorable timing to lock in lower prices.

If you’re looking to reduce your costs without compromising on quality, there are several smart strategies you can use to optimize your purchase decisions. These tips apply whether you’re sourcing for packaging, signage, construction protection, or another application.

Bulk purchasing is one of the most effective ways to lower your per-unit cost. Suppliers often offer tiered pricing based on volume, and placing larger, consolidated orders can also reduce freight costs. Polyflute provides scalable pricing for medium to high-volume orders, making it easier for clients to plan ahead and save in the long run.

Customization always adds complexity and cost. Whenever possible, opt for standard sheet sizes like 2440mm × 1220mm (8ft × 4ft). These are produced in high volumes and stocked by most suppliers, reducing lead times and manufacturing surcharges. Custom cuts or die-shaped designs may be necessary in some cases, but should be reserved for when absolutely essential.

Shipping corflute sheets can be costly due to their volume and packaging requirements. If time or cost is a concern, consider working with local distribution centers or regional warehouses. Ask your supplier—such as Polyflute—if they have fulfillment partners or stock points near your project location. This can significantly reduce shipping delays and costs.

Don’t make the mistake of focusing solely on the per-square-meter price. Always calculate the total cost of ownership, which includes:

Being aware of these hidden costs will help you avoid unpleasant surprises and budget more accurately.

Before committing to a large purchase, always ask for physical samples. This gives you a chance to evaluate the sheet’s rigidity, surface smoothness, print performance, and structural integrity. It’s also a great opportunity to test compatibility with your intended use, whether that’s digital printing, screen printing, or mechanical fabrication.

Additionally, building a relationship with a responsive supplier can open the door to trial orders, better payment terms, and early access to new product types or stock clearances—all of which can add long-term savings.

The price of corflute sheets depends on a variety of factors, including material cost, size, thickness, customization, and logistics. While market prices fluctuate, understanding what drives these changes can help buyers make informed and budget-conscious decisions.

Suppliers like Polyflute play a crucial role in maintaining stable prices and ensuring product consistency. By leveraging their manufacturing expertise and customer-first approach, you can get reliable products at a competitive rate—whether you’re ordering standard signage sheets or UV-stabilized construction panels.

To learn more or request a custom quote, get in touch with Polyflute’s sales team today. With the right planning and supplier, you can maximize value and minimize costs.