Corrugated plastic sheets are lightweight, waterproof, and highly durable panels widely used in construction, agriculture, signage, packaging, and DIY projects. From clear corrugated plastic sheets for greenhouses to black corrugated plastic sheets 4×8 for outdoor shelters, they offer practical solutions in both industrial and home settings.

As demand grows, so do the options—thicknesses from 3mm to 8mm, sizes like 24 x 36 or 48 x 96, and even heavy duty corrugated plastic roofing sheets. But which type suits your needs? In this guide, we’ll explore types, sizes, colors, and how to choose the right corrugated plastic sheets, whether for personal use or wholesale purchase.

Corrugated plastic sheets, sometimes referred to as corrugated polypropylene sheets or coroplast sheets, are rigid, fluted thermoplastic panels made from polypropylene or polyethylene. Their defining feature is a twin-wall or multi-wall structure that creates air pockets between two flat plastic surfaces. This corrugated core gives the sheet both light weight and exceptional strength, making it ideal for applications where durability and portability are key.

Unlike traditional materials like cardboard, wood, or even metal, corrugated plastic sheets offer superior resistance to water, chemicals, UV rays, and mold. They’re also 100% recyclable and non-toxic, making them an environmentally friendlier option in many use cases.

At their core, these sheets feature a fluted plastic design, much like the structure of cardboard but made entirely from plastic. This fluted center traps air and adds stiffness without significantly increasing weight. Most corrugated plastic sheets are made using polypropylene (PP) or polyethylene (PE):

Corrugated plastic sheets are used in a wide variety of industries and everyday scenarios, including:

With their increasing popularity across various industries, corrugated plastic sheet now come in many different types to suit a wide range of applications. Whether you’re looking for heavy duty corrugated plastic roofing sheets, clear panels for a greenhouse, or black corrugated plastic sheet 48 x 96 for outdoor enclosures, understanding the available types can help you choose the most suitable option for your project.

Polypropylene Corrugated Sheets (PP)

Most common type.

Lightweight, cost-effective, and suitable for signage and packaging.

Ideal for indoor and short-term outdoor use.

Polyethylene Corrugated Sheets (PE)

Heavier and tougher.

More flexible and impact-resistant.

Suitable for roofing, agriculture, or longer-term outdoor applications.

PVC Corrugated Sheets

Rarely used in the same form as PP/PE corrugated plastic.

Commonly found in rigid roofing panels rather than fluted designs.

Higher fire resistance, but heavier and more expensive.

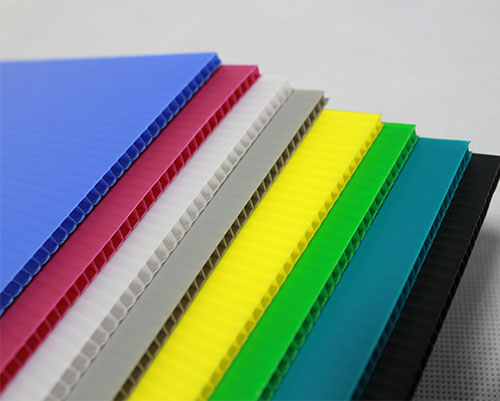

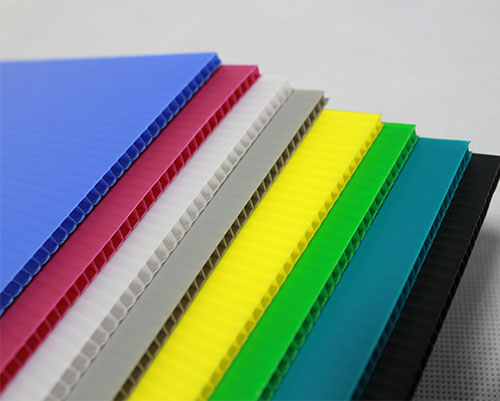

Color is more than just an aesthetic decision—it often plays a role in functionality:

Clear Corrugated Plastic Sheets

Allow light transmission.

Perfect for greenhouses, skylights, garden roofs, or sunrooms.

Often available as 4×8 clear corrugated plastic sheets or 3m corrugated plastic roofing sheets near me.

Black Corrugated Plastic Sheet

Block light and UV rays.

Great for shielding sensitive materials, privacy barriers, and signage backgrounds.

Common size: black corrugated plastic sheets 4×8 and black corrugated plastic sheets 48 x 96.

White Corrugated Sheets

Provide reflectivity and a neutral appearance.

Often used in advertising signs and displays.

Colored Sheets (Blue, Yellow, Red, etc.)

Frequently used in logistics for color coding.

Ideal for custom branding, directional signage, or organizing materials.

Corrugated plastic sheet come in many size variants depending on the application. Here are some common sizes:

| Size (inches) | Metric Approx. (mm) | Common Use Cases |

|---|---|---|

| 24 x 36 | 610 x 914 | Small signs, dividers, craft projects |

| 24 x 48 | 610 x 1220 | Indoor signage, DIY partitions |

| 36 x 48 | 914 x 1220 | Larger signage or packaging panels |

| 48 x 48 | 1220 x 1220 | Medium-size walls, backboards |

| 48 x 96 (4×8 ft) | 1220 x 2440 | Roofing, walls, large enclosures, general industrial use |

| Custom-cut sizes | – | Can be ordered in bulk for specific needs |

The thickness of the sheet directly affects its rigidity, weight, and durability. Common thicknesses include:

| Thickness | Ideal For |

|---|---|

| 2mm–3mm | Signs, indoor displays, lightweight packaging |

| 4mm | Standard signage, medium-strength enclosures |

| 5mm–6mm | Outdoor signage, roofing with support |

| 8mm | Heavy-duty roofing, structural applications, high-impact usage |

Some users may refer to 3mm corrugated plastic sheets, 4mm corrugated plastic sheets, or 8mm corrugated plastic sheets depending on their specific project requirements.

Standard Corrugated Plastic Sheets

Heavy Duty Corrugated Plastic Roofing Sheets

Choosing the right size and dimensions of corrugated plastic sheet is essential for ensuring optimal performance, easy installation, and minimal waste. Whether you’re working on a greenhouse, signage project, or a custom roof, the dimensions of your sheet must match the functional and structural requirements of the task.

Let’s explore the most widely available sheet sizes, how they’re typically used, and what to consider when selecting the right size for your application.

Here are the most commonly available sheet sizes in both inches and millimeters:

| Size (Imperial) | Size (Metric) | Common Uses |

|---|---|---|

| 24 x 36 inches | 610 x 914 mm | Indoor signs, packaging dividers, art projects |

| 24 x 48 inches | 610 x 1220 mm | Medium-sized signage, lightweight temporary walls |

| 36 x 48 inches | 914 x 1220 mm | Visual displays, directional signage, floor protection |

| 48 x 48 inches | 1220 x 1220 mm | Partitions, advertising boards, modular constructions |

| 48 x 96 inches (4×8 ft) | 1220 x 2440 mm | Roofing, construction barriers, agriculture and greenhouses |

The 48 x 96 corrugated plastic sheets are among the most popular and versatile options. They provide excellent surface area and are especially useful in outdoor environments where coverage and strength are priorities.

For roofing and outdoor shelters, longer sheet options like 3m corrugated plastic roofing sheets are commonly used. These provide coverage with fewer seams, which helps improve waterproofing and wind resistance.

Typical roofing dimensions include:

When purchasing 3m corrugated plastic roofing sheets near me, ensure the supplier offers UV protection and anti-drip options if you’re using them in greenhouses or livestock shelters.

Many wholesale corrugated plastic sheet providers allow for custom-cut sizes upon request, especially for bulk orders. This is helpful in industries like:

Additionally, most corrugated plastic sheets—especially 3mm, 4mm, or 5mm sheets—can be easily trimmed using utility knives or circular saws.

While choosing sheet dimensions, the thickness should align with size and purpose. For example:

If you’re planning to use these materials in large quantities, sourcing wholesale corrugated plastic sheet offers multiple advantages:

Industrial buyers often prefer bulk orders of black corrugated plastic sheet 48 x 96 or clear corrugated plastic sheets 4×8 depending on whether visibility or protection is prioritized.

One of the most crucial factors when selecting corrugated plastic sheet is the thickness. The thickness directly impacts the material’s strength, flexibility, insulation capability, and overall suitability for specific applications.

In this section, we’ll look at the most common thicknesses—ranging from 2mm to 8mm and beyond—and explore how each is used in real-world settings, including signage, construction, packaging, and roofing.

Here’s a breakdown of widely available thicknesses and their general characteristics:

| Thickness | Metric Equivalent | Typical Applications |

|---|---|---|

| 2mm | ~0.08 inches | Lightweight signs, arts and crafts, indoor use |

| 3mm | ~0.12 inches | Indoor signage, packaging layers, temporary displays |

| 4mm | ~0.16 inches | Outdoor signage, greenhouse panels, basic roofing |

| 5mm | ~0.20 inches | Display panels, protective sheeting, semi-permanent roofs |

| 6mm | ~0.24 inches | Long-term roofing, protective walls, construction barriers |

| 8mm | ~0.31 inches | Heavy-duty roofing, structural panels, agriculture sheds |

Let’s examine each one in more detail.

3mm corrugated plastic sheets are a popular choice for lightweight applications. They offer a balance between flexibility and durability.

Use Cases:

Election signs

POP (point-of-purchase) displays

Temporary partitions

Inner packaging dividers

Advantages:

Easy to cut and print on

Cost-effective for short-term or indoor use

4mm corrugated plastic sheets are considered the “standard” thickness for signage and light-duty roofing.

Use Cases:

Outdoor advertisements

Wall cladding in utility spaces

Greenhouse covers (clear version)

Protective table or shelf liners

Advantages:

Excellent printability and moderate strength

UV-resistant versions available

When projects require more rigidity and weather resistance, 5mm or 6mm sheets are ideal.

Use Cases:

Garden shed roofing

Portable walls or exhibition panels

Long-term outdoor signage

Vehicle trunk liners or cargo bay protectors

Advantages:

Higher durability

Less prone to flexing or sagging over time

For heavy-duty and structural applications, 8mm corrugated plastic sheets are used.

Use Cases:

Livestock shelters

Permanent roof enclosures

Sound barriers

Industrial worksite partitions

Advantages:

Superior impact resistance

Greater thermal and acoustic insulation

Supports weight and wind loads better than thinner sheets

When deciding on thickness, consider the following:

| Application Type | Recommended Thickness |

|---|---|

| Indoor signs / craft | 2mm – 3mm |

| Outdoor signage | 4mm – 5mm |

| Temporary roofing | 4mm – 5mm |

| Permanent roofing | 6mm – 8mm |

| Structural or protective | 6mm – 8mm |

Also, thicker sheets typically cost more and are heavier, so be sure to balance budget with performance.

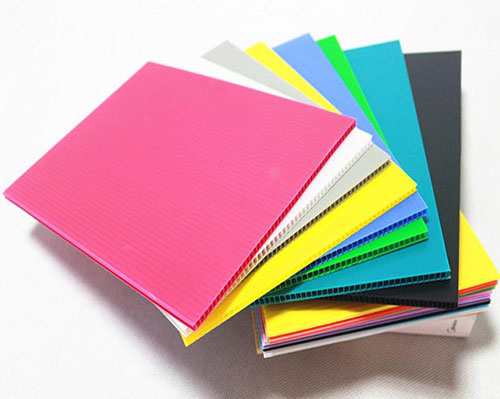

Corrugated plastic sheets are available in a wide variety of colors, and the choice of color goes far beyond just aesthetics. Color selection can influence light transmission, temperature control, UV resistance, visibility, and the overall performance of the material in specific environments.

Let’s explore the most common colors available on the market, and what each one is best suited for.

Here’s a quick overview of the most popular corrugated plastic sheet colors and their typical applications:

| Color | Common Uses | Key Benefits |

|---|---|---|

| Clear | Greenhouses, skylights, indoor partitions | High light transmission, transparency |

| White | Signage, packaging, cleanroom walls | Reflects heat, neutral background for printing |

| Black | Industrial walls, privacy panels, roofing | UV-resistant, opaque, professional appearance |

| Blue | Safety barriers, branding displays | Visible, eye-catching, often used in hospitals |

| Red | Warning signs, event promotions | High visibility, draws attention |

| Yellow | Safety signage, construction sites | Cautionary use, standout visibility |

| Green | Agriculture, landscaping, eco-themed displays | Natural appeal, moderate light filtering |

| Grey | Roofing, interior partitions, soundproofing | Subdued tone, hides dirt, neutral aesthetic |

Let’s look at some in more detail.

Clear corrugated plastic sheets are among the most widely used in agriculture, particularly for greenhouses and garden covers.

Key Features:

High transparency (~85% light transmission)

UV-stabilized versions for long-term sun exposure

Available in 4×8 clear corrugated plastic sheet or longer roofing panels

Ideal For:

Greenhouses and cold frames

Patio enclosures

Sunrooms

Black corrugated plastic sheets are commonly used for industrial, transport, and outdoor roofing purposes due to their durability and UV resistance.

Variants:

Black corrugated plastic sheet 4×8

Black corrugated plastic sheet 48 x 96

Benefits:

Full opacity, ideal for privacy or sun-blocking

Hides stains and dust in rugged environments

Can absorb and retain heat—useful in colder areas

Best Applications:

Outdoor sheds

Vehicle panels

Temporary site enclosures

White corrugated plastic sheets are favored for sign printing and interior cladding. Lighter colors reflect heat and offer a neutral background.

Best For:

Exhibition signs

POP displays

Medical and food processing walls (where cleanliness matters)

Light Blue / Grey Sheets:

Used in clean environments or minimalist builds

Popular in tech facilities and office partitions

Brightly colored sheets—such as red, yellow, and blue—are often used in branding, retail displays, and safety signage.

Benefits:

Stand out in busy environments

Offer quick color-coded identification

Enhance visual safety (e.g., caution panels, exits, and hazards)

Where to Use:

Event booths

Directional signs

Industrial zoning and marking

Corrugated plastic sheet is incredibly versatile materials that serve industries ranging from agriculture and construction to signage, packaging, and DIY applications. Their lightweight build, weather resistance, affordability, and availability in a variety of colors, sizes, and thicknesses make them a preferred choice over traditional materials like metal, wood, or glass in many use cases.

When selecting the ideal sheet, it’s essential to consider:

Whether you’re looking for clear corrugated plastic sheet for your greenhouse, heavy duty corrugated plastic roofing sheets for weatherproof shelter, or colorful options for safety signage, understanding these features will help you make informed decisions that match your project’s needs and budget.

Looking to buy in bulk? Partnering with wholesale corrugated plastic sheet supplier – Polyflute, ensures access to custom colors, dimensions, and competitive pricing. Don’t hesitate to request samples or product certifications to confirm material quality and longevity.

Let your next project be strong, smart, and cost-effective—with the right corrugated plastic sheets at its core.