Corrugated plastic boxes have become an essential material in various industries due to their durability, versatility, and cost-effectiveness. In this comprehensive guide, we will explore what corrugated plastic boxes are, how they are manufactured, the different types available, their applications, as well as their advantages and disadvantages.

What Are Plastic Corrugated Boxes and How Do They Work?

Plastic corrugated boxes, also known as corrugated polypropylene (PP) boxes or simply correx boxes, are a type of packaging material made from a fluted plastic sheet sandwiched between two flat layers of plastic. This structure resembles the traditional cardboard box but with the added benefits of being more durable, lightweight, and resistant to moisture, chemicals, and physical wear.

The “fluted” structure of corrugated plastic boxes allows them to be both lightweight and strong. The design helps distribute weight evenly, making them a preferred choice for packaging and transporting goods. These boxes are widely used for a range of applications, from shipping fragile items to storing products in industrial settings.

How Do They Work?

Corrugated plastic boxes work by combining the flexibility and strength of plastic materials with the superior cushioning provided by the fluted core. The plastic layers form a protective shell, and the air gaps between the flutes act as shock absorbers, ensuring that the contents remain safe during transportation and handling. This unique combination of properties makes plastic corrugated boxes an ideal solution for a wide variety of uses.

How Are Corrugated Plastic Boxes Manufactured?

The manufacturing process of plastic corrugated boxes involves several steps, with the most common material used being polypropylene (PP). Here’s a breakdown of the steps involved:

- Material Selection

The primary material for manufacturing plastic corrugated boxes is polypropylene (PP). It is chosen for its lightweight, durable, and flexible properties. Other plastics, such as polyethylene (PE), can also be used, depending on the intended application.

- Extrusion of Plastic Sheets

The first step in the process is extrusion, where polypropylene plastic is melted and formed into large flat sheets. These sheets are then cooled and solidified.

- Flute Formation

In the next stage, the flat sheets are passed through specialized machinery that creates the “fluted” or corrugated structure. The flutes are formed by a machine that presses the sheets into wave-like shapes, which are then bonded to two smooth layers of plastic.

- Cutting and Shaping

The corrugated plastic sheet is then cut into the desired sizes and shapes based on the specifications of the box. This step ensures that the boxes are customized to meet the requirements of the intended use, whether for storage, transportation, or display.

- Printing and Customization

Many corrugated plastic boxes are customized with branding, logos, or product information. This is done through various printing methods such as screen printing or digital printing. Customization options may also include adding handles, vents, or reinforcement materials.

- Assembly and Final Inspection

Once the boxes are cut and customized, they are assembled and undergo quality control checks to ensure that they meet durability and safety standards. Any necessary modifications or additional features are added at this stage.

The end result is a durable, versatile, and highly customizable plastic corrugated box that can be used in a wide variety of applications.

What Are the Different Types of Plastic Corrugated Boxes?

Plastic corrugated boxes come in a wide range of types, each offering unique features and benefits to suit various applications. These boxes are designed with different structural designs, flute profiles, and materials to enhance their durability, strength, and flexibility. Below is a breakdown of the different types of plastic corrugated boxes:

1. Plastic Profile Board

2. Triple-Wall Corrugated Plastic Boxes

- Description: These boxes feature three layers of fluting, providing superior stability, increased compression strength, and better cushioning properties. Triple-wall boxes are ideal for heavy-duty applications and protecting fragile items.

- Applications: Shipping large or heavy items, industrial storage.

3. Double-Wall Corrugated Plastic Boxes

- Description: With two layers of fluting, double-wall corrugated boxes offer additional strength compared to single-wall options. These boxes are perfect for storing or shipping heavier products that require extra support.

- Applications: Shipping and storing large items, industrial uses.

4. Single-Wall Corrugated Plastic Boxes

- Description: The most basic form of corrugated plastic boxes, featuring one layer of fluting between two outer layers. This design offers cost-effective, lightweight protection for items that do not require excessive strength.

- Applications: General packaging and shipping of lightweight products.

5. Honeycomb Corrugated Plastic Boxes

- Description: These boxes feature a honeycomb pattern within the corrugated structure, offering a combination of flexibility, lightweight, and strength. The design allows for better compression resistance while keeping the box light.

- Applications: Ideal for transporting non-fragile items that need some protection without the need for heavy-duty strength.

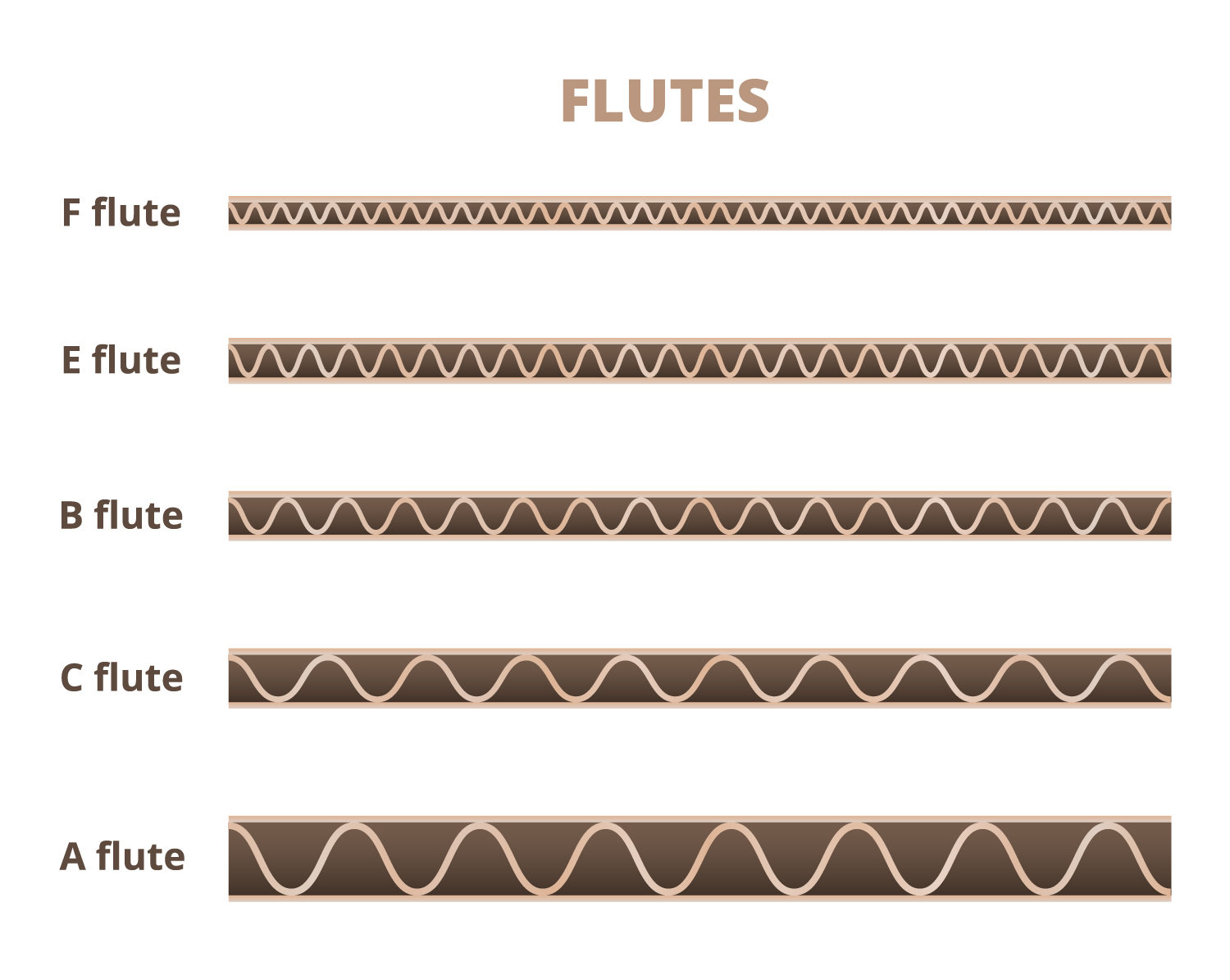

6. Flute Profiles

- A-Flute: The original flute design with approximately 33 flutes per linear foot and a thickness of about 1/4 inch. Offers good cushioning for fragile items.

- B-Flute: A flute profile with around 47 flutes per linear foot and a thickness of 1/8 inch. Ideal for canned goods and packaging small to medium-sized items.

- C-Flute: With approximately 39 flutes per linear foot and a thickness of 5/32 inch, C-flute is commonly used for shipping cartons and larger packaging needs.

- E-Flute: Features around 90 flutes per linear foot and a thickness of 1/16 inch, perfect for lightweight, small, retail packaging.

- F-Flute: Contains about 125 flutes per linear foot and a thickness of 1/32 inch, typically used for small, delicate retail packaging.

7. Divider/Partitioned Corrugated Plastic Boxes

- Description: These boxes have built-in partitions that divide the box into smaller compartments. They are custom-designed for organizing and protecting items during transportation.

- Applications: Packaging and shipping delicate or small items, such as electronics or components.

8. Plastic Corrugated Boxes With a Double Cover

- Description: Featuring a body made from square or rectangular tubing with interchangeable telescopic covers, these boxes offer enhanced protection and are stored flat until needed. The interlocking design provides additional stability.

- Applications: Shipping large or bulky items, such as appliances or machinery.

9. Plastic-Handled Corrugated Plastic Boxes

- Description: These boxes come with integrated plastic handles for easy carrying and handling. They are designed for improved convenience, especially when transporting fragile or bulky components.

- Applications: Shipping or storing fragile items where ease of handling is important.

10. Corrugated Plastic Mailers

- Description: Lightweight yet durable, these boxes are perfect for protecting products during shipment. Often used in e-commerce and subscription boxes, they are customizable in terms of size, color, and branding.

- Applications: E-commerce, subscription box packaging, and shipping of individual or small items.

11. Slotted Plastic Corrugated Boxes

- Description: These boxes are made from pre-scored, slotted corrugated plastic, which allows for easy assembly. They come in various designs, such as regular slotted, half-slotted, and full overlap boxes, providing different levels of support for different applications.

- Applications: General packaging, shipping, and storage.

12. Telescopic Plastic Corrugated Boxes

- Description: Featuring a two-piece design with a lid that can extend over the bottom tray, telescopic boxes offer enhanced stacking strength and easy access to the contents. These are commonly used for heavier or bulkier items.

- Applications: Secure packaging, shipping, and product display.

13. Rigid Plastic Corrugated Boxes

- Description: Rigid corrugated plastic boxes are made of two end panels and a central section. These boxes are self-erecting and are ideal for applications requiring more structural strength.

- Applications: Packaging for heavy-duty or large items.

14. Folding Corrugated Plastic Reusable Boxes

- Description: These boxes feature a solid base with overlapping flaps that can be folded around products. Their compact and reusable design makes them ideal for transporting smaller items.

- Applications: Shipping and storing smaller items like books or printed materials.

15. Auto Bottom Tuck-Top Boxes

- Description: Designed for quick and easy closure, these boxes feature a tuck flap that fits into the body, making them simple to close and secure. Variations of this design include snap-lock bottoms for added strength.

- Applications: Packaging for small to medium-sized items that require efficient and easy closure.

Each type of plastic corrugated box offers specific benefits depending on the application, making them a versatile solution for a variety of industries, including logistics, packaging, shipping, and storage. Whether you’re looking for lightweight protection for fragile items or a durable solution for bulk shipping, there’s a corrugated plastic box type suited to your needs.

Applications, Advantages, and Disadvantages of Plastic Corrugated Boxes

Applications

Plastic corrugated boxes are used in a wide range of industries due to their strength, flexibility, and versatility. Some common applications include:

- Packaging and Shipping

Plastic corrugated boxes are widely used for packaging and shipping products. Their lightweight nature makes them ideal for reducing shipping costs while still providing protection for fragile or sensitive items.

- Storage Solutions

Corrugated plastic storage boxes are used in warehouses, factories, and retail stores for organizing inventory. They are resistant to moisture, dust, and dirt, ensuring that items remain clean and secure during storage.

- Agriculture

In the agricultural sector, corrugated plastic boxes are used to transport and store produce. Their durability and resistance to water make them ideal for handling fresh fruits, vegetables, and other perishable goods.

- Retail Display

Corrugated plastic boxes are also used in retail environments for displaying products. Their ability to be customized with branding and graphics makes them a popular choice for point-of-sale displays.

- Medical and Pharmaceutical

In the medical field, corrugated plastic boxes are used for transporting sensitive medical supplies and equipment. Their strength and resistance to chemicals ensure that products remain intact during transportation.

Advantages

- Durability: Plastic corrugated boxes are more durable than traditional cardboard boxes, able to withstand rough handling, moisture, and extreme temperatures.

- Lightweight: Despite their strength, plastic corrugated boxes are lightweight, which makes them easier and more cost-effective to transport.

- Water-Resistant: Unlike cardboard boxes, which can become weakened or damaged when exposed to moisture, plastic corrugated boxes remain intact even in wet conditions.

- Customizability: These boxes can be tailored to meet specific requirements in terms of size, strength, design, and branding, making them ideal for various applications.

- Recyclable and Eco-Friendly: Many plastic corrugated boxes are made from recyclable materials, contributing to environmental sustainability.

Disadvantages

- Cost: Plastic corrugated boxes tend to be more expensive than cardboard boxes, which may make them less suitable for low-budget operations.

- Not Biodegradable: While recyclable, plastic corrugated boxes are not biodegradable, which can raise concerns about their environmental impact in some cases.

- Limited Flexibility: While they are highly durable, plastic corrugated boxes can be less flexible than cardboard in terms of shaping and bending, which may limit their use in some applications.

Conclusion

Plastic corrugated boxes provide a robust, versatile, and cost-effective packaging solution for a wide range of industries. Their durability, water resistance, and customizability make them an ideal choice for businesses looking for reliable and environmentally friendly packaging solutions. Whether you are looking for corrugated plastic storage boxes with frames, custom corrugated polypropylene boxes, or specialized packaging such as honeycomb boxes or mining core boxes, plastic pp corrugated boxes offer an array of benefits and applications to meet your needs. However, businesses must also weigh the costs and potential environmental impact of using plastic in their operations.

| Welcome to contact us now.

We will get back to you within 8 hours. We will offer latest price and free sample.