Corrugated Plastic Sheets Price can vary significantly based on several factors, making it important for businesses and individuals to understand the pricing dynamics. These versatile sheets are commonly used in industries such as construction, advertising, packaging, and agriculture due to their durability, lightweight nature, and ability to withstand harsh outdoor environments. Made from high-quality polymers like polypropylene (PP) or polyethylene (PE), they are ideal for applications including temporary signs, lightweight barriers, packaging, and even roofing materials in specific scenarios.

However, various elements influence the price of corrugated plastic sheets, and there can be considerable price fluctuations. Whether you’re planning to use these sheets in a small project or need to purchase in bulk for your business, understanding the key factors that affect pricing and how to maximize value for money is essential. In this article, Polyflute will explore the factors influencing Corrugated Plastic Sheets Price and provide practical advice to help you make an informed purchasing decision based on your budget and needs.

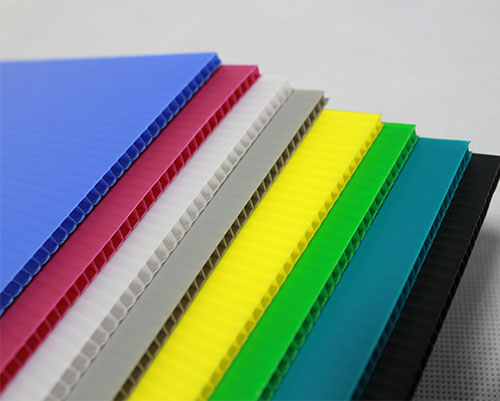

Corrugated plastic sheets are lightweight, durable sheets made by bonding two flat layers of plastic with a corrugated (fluted) core between them. The corrugated design provides strength while keeping the overall weight low, which makes these sheets incredibly useful for a range of applications. These sheets are often made from materials like polypropylene (PP) or polyethylene (PE), both of which are highly resistant to UV rays, weather, and physical stress. Common thicknesses for corrugated plastic sheets range from 2mm to 10mm, with 4mm and 6mm being the most commonly used.

The unique feature of this sheet is its corrugated core structure, which effectively distributes weight and forces, making it both strong and lightweight. Unlike traditional solid plastic sheets, the corrugated structure better distributes pressure and impact forces, significantly improving the overall durability of the material without significantly increasing weight. This makes corrugated plastic sheets an ideal choice for a variety of applications that require both strength and lightness.

Corrugated plastic sheets are widely used in a variety of industries due to their excellent durability, versatility and lightweight properties. Here are some common applications:

An important factor affecting the price of corrugated plastic board is its thickness. The thicker the board, the greater the amount of material required and the higher the manufacturing cost. According to different thicknesses, the price can be roughly divided into the following categories:

The type of material used in the production of corrugated plastic board has a great impact on its price. The choice of different materials will directly affect the performance, durability and cost of the board. Some common materials include:

The price per unit can vary greatly depending on the quantity purchased. Buying in bulk typically results in a lower price per square foot. For instance, bulk purchases of 1000 square feet or more may result in a price reduction of 10-20% compared to retail prices. Some suppliers may also offer custom sizes or pre-cut sheets, which could affect the price based on customer requirements.

The cost of raw materials, especially the prices of polypropylene (PP) and polyethylene (PE), is closely related to the fluctuations in the global commodity market. Polypropylene and polyethylene are the main raw materials for manufacturing corrugated plastic sheets, and the prices of these plastic polymers are greatly affected by the fluctuations in crude oil prices.

The manufacturing process of the sheet can also influence the price. Basic corrugated plastic sheets are made using an extrusion process, where plastic is melted and formed into sheets. However, more advanced manufacturing methods, such as co-extrusion (where two or more materials are combined into a single sheet), result in higher production costs and thus higher prices.

Transportation and supply chain issues play a significant role in the overall cost of corrugated plastic sheets. Shipping large quantities of corrugated plastic sheets from manufacturers to suppliers or directly to end users can add a significant cost, particularly if the materials are being shipped internationally.

Economic conditions and demand for corrugated plastic sheet can also affect prices. During times of high demand, such as during a major construction project or a large advertising campaign, suppliers may increase corrugated plastic sheets prices to make up for low inventory. Similarly, global events such as material shortages or trade tariffs can affect production and shipping costs, leading to higher prices.

The price of corrugated plastic sheets can vary significantly depending on where they are purchased. For example, the price of these sheets may be higher in countries where plastic production is not as widespread, due to the cost of importation. On the other hand, in countries with a high supply of corrugated plastic manufacturers (such as China or the United States), the prices tend to be more competitive.

When choosing corrugated plastic sheets, one of the most important factors to consider is how you plan to use them. Corrugated plastic sheets price can vary depending on the application, and it’s essential to match the sheet’s characteristics to your project requirements. Here are some common considerations:

While the thickness and material type are the main factors affecting the cost of corrugated plastic sheets, additional features can also influence the price. Some manufacturers offer UV-resistant coatings, flame retardant properties, or anti-static treatments. These features can increase the price but may be essential for specific applications, such as outdoor signage in high-sun environments or industrial packaging requiring flame resistance.

The price of corrugated plastic sheeting is affected by many factors, and as a manufacturer, we understand how material type, thickness, special properties, production process, and shipping costs directly affect the final quote. When choosing corrugated plastic sheeting for your project, we recommend that you consider these factors comprehensively, which can help you make a more reasonable purchasing decision.

Whether you are using it for temporary signage, industrial packaging, or outdoor applications, we always emphasize finding the best balance between quality and cost. We offer a wide range of products to suit different needs, and our goal is to ensure that every customer can get a high-quality product that meets actual needs at the most suitable price.

When choosing corrugated plastic sheeting, please be clear about your application needs. If you only need it for a short period of time, we have a cost-effective solution; if your needs are for long-term outdoor use, we also have durable and high-quality options. We recommend that you compare quotes from different suppliers and take advantage of bulk purchase discounts or special offers to ensure that you get the most competitive price. If you have any purchasing needs, please contact Polyflute.