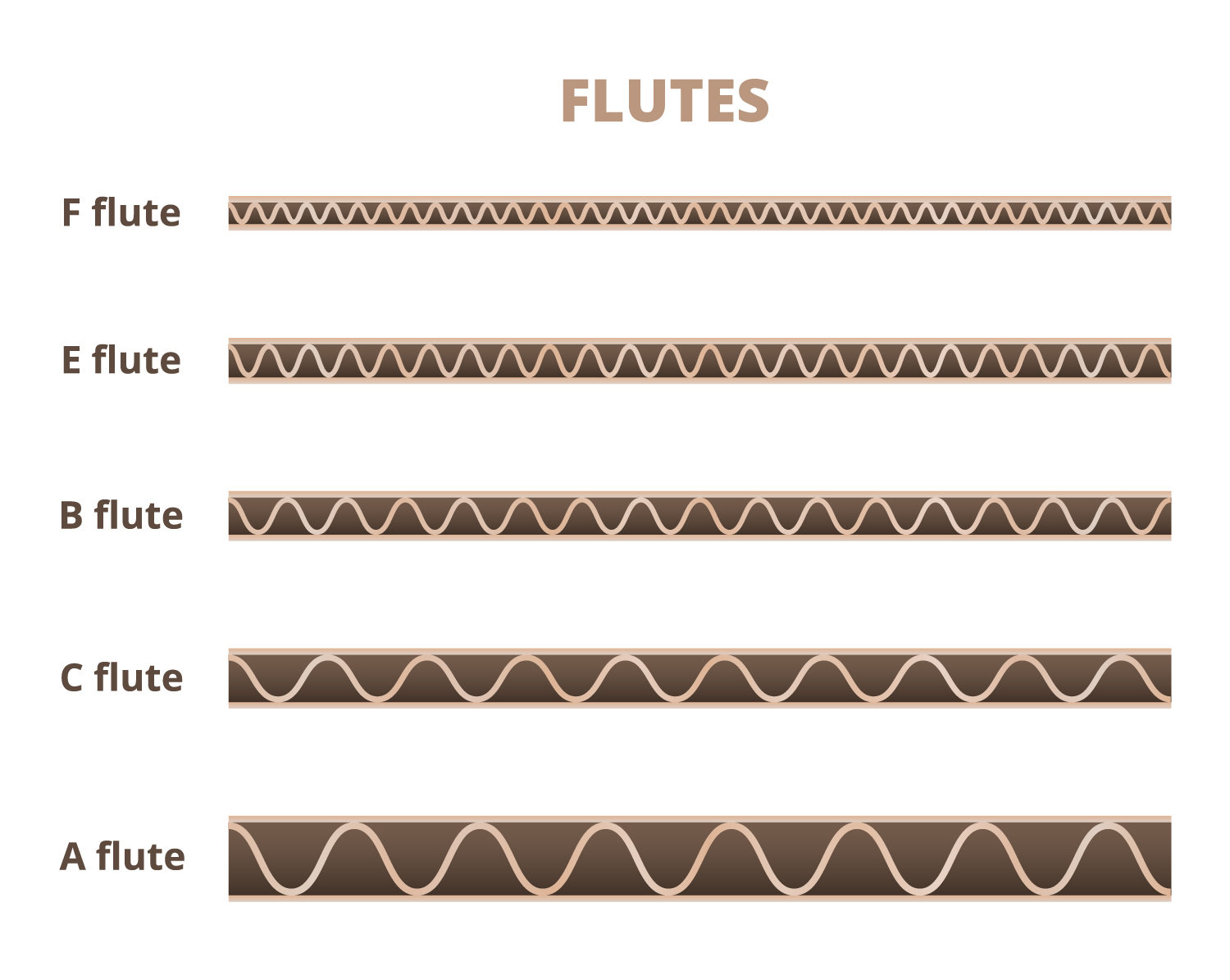

In the world of packaging, one of the most crucial materials used for its strength and versatility is corrugated board. Its ability to protect products during transport, storage, and handling makes it indispensable in industries ranging from retail to logistics. A key component of corrugated board is its flute, the wavy structure sandwiched between the two flat liners of the board. This flute plays a vital role in determining the board’s strength, durability, and overall performance in packaging.

One of the most important factors in selecting corrugated board for packaging is understanding the corrugated flute size. The size of the flute impacts everything from the strength of the packaging to the ability to absorb shock during shipping. Whether you’re shipping fragile electronics, heavy-duty industrial equipment, or everyday consumer goods, choosing the right corrugated flute size ensures your products are well-protected throughout their journey.

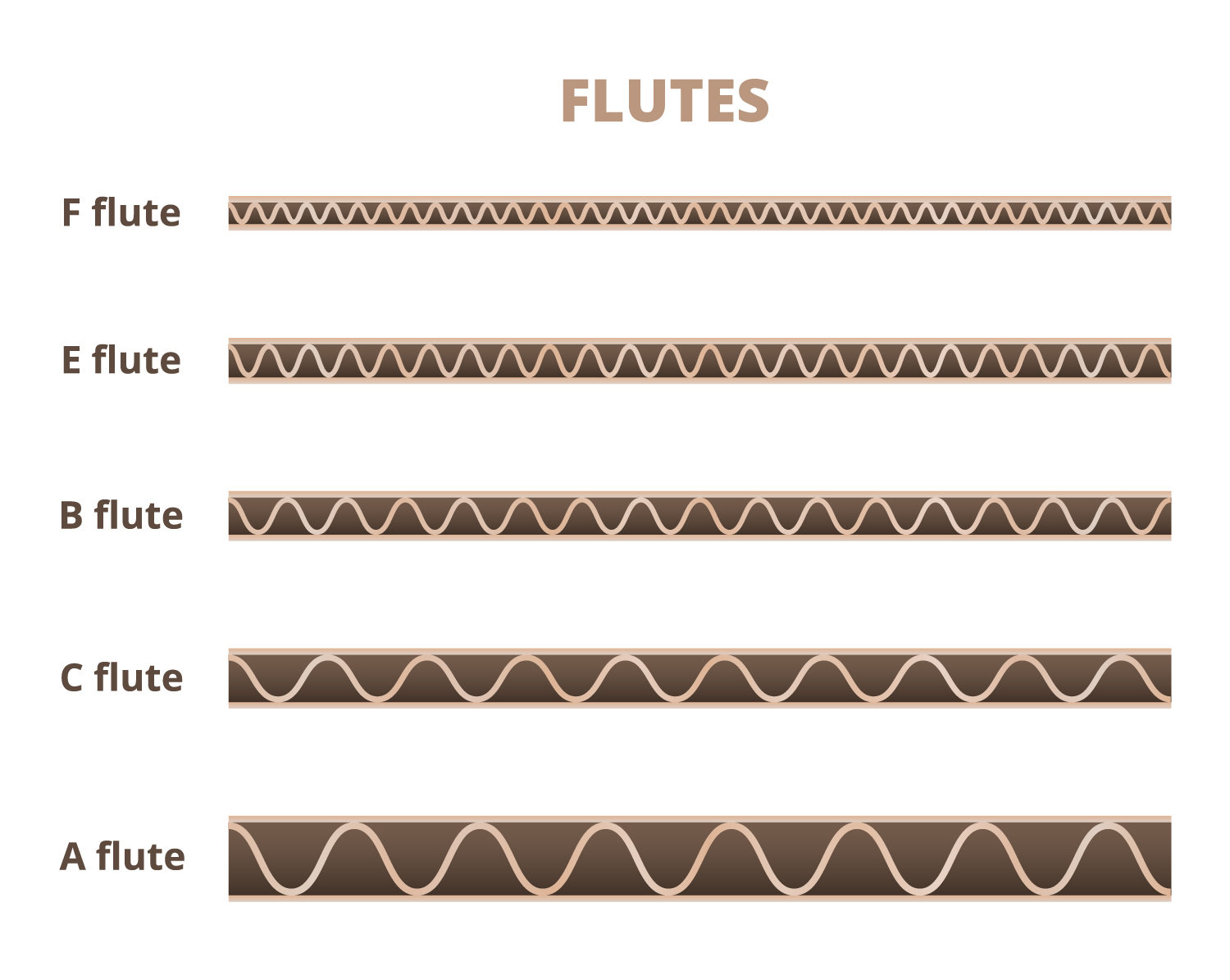

This article delves into the different corrugated flute sizes, their impact on packaging performance, and how choosing the right flute size is essential for ensuring the efficiency and cost-effectiveness of your packaging. At Polyflute, we are experts in providing high-quality corrugated materials, offering a range of flute sizes to meet the diverse needs of our clients.

When discussing corrugated board, the term flute size refers to the thickness of the wavy layer that lies between the two liners of the cardboard. The flute provides the material with its strength and cushioning properties. It is critical in determining how much weight a piece of corrugated board can support, as well as how well it absorbs shocks and protects the contents inside.

The flute size is classified by its height, which directly affects the board’s rigidity, strength, and overall performance. Flute size impacts the physical characteristics of the corrugated board, such as its ability to resist compression and bending, its ability to withstand external forces, and how much it can cushion items during transit.

At Polyflute, we understand that choosing the correct corrugated flute size can make or break the efficiency of your packaging. For instance, larger flute sizes offer more cushioning, while smaller flutes offer more stacking strength and are ideal for products that need precise, more compact packaging. As experts in the field, we offer a range of flute sizes to suit various needs, helping businesses optimize their packaging solutions.

Corrugated board is made up of different flute sizes, each offering distinct advantages for specific packaging needs. These flute sizes are categorized based on the height and thickness of the wave-like structure, which directly influences the strength, cushioning, and flexibility of the board. Understanding the various corrugated flute sizes will help you select the ideal material for your packaging applications.

A-flute is the largest of the common flute sizes, with a height of approximately 5mm. It is known for its excellent cushioning properties, making it an ideal choice for protecting fragile items during transport. A-flute offers a high level of shock absorption, which is particularly beneficial for sensitive products such as glassware, electronics, and large appliances.

A-flute provides outstanding protection but does have a trade-off in terms of stacking strength. Its larger size means that it may not be as efficient for stacking large quantities of products. However, for heavier or more fragile items, the benefits of using A-flute far outweigh the drawbacks.

B-flute is a smaller size than A-flute, with a height of about 3mm. It provides a balanced combination of strength and cushioning, making it suitable for a wide range of packaging needs. B-flute offers a smooth surface that works well for printing, which is why it is often used for retail packaging and point-of-sale displays.

Products that require moderate protection during transit, such as small electronics, books, and cosmetics, are typically packaged with B-flute. Its ability to maintain strength while providing cushioning makes it a versatile flute size for businesses across various industries.

C-flute is one of the most commonly used flute sizes in corrugated board packaging. With a height of approximately 4mm, C-flute strikes a good balance between cushioning, strength, and stackability. It is widely used in the packaging of medium-weight products such as clothing, food items, and home appliances.

C-flute offers a higher stacking strength compared to A-flute, making it suitable for stacking boxes on top of each other during transport. Its versatility and widespread use in packaging make C-flute a popular choice for businesses that need reliable performance and durability.

E-flute is smaller in height, measuring around 1.5mm, and offers superior strength for its size. Despite its small stature, E-flute provides an efficient, lightweight alternative to larger flutes, making it ideal for high-end retail packaging and applications where presentation is important. The smooth surface provided by E-flute is excellent for printing detailed designs, making it the preferred choice for packaging high-quality consumer goods like electronics, cosmetics, and luxury products.

E-flute is also highly efficient in terms of space usage, offering both strength and a compact design. It is perfect for businesses looking to save on storage space while ensuring that their products are protected and look appealing on the shelf.

F-flute is the smallest of the common flute sizes, with a height of around 1mm. Despite its compact size, F-flute is a strong and durable choice for lightweight packaging. It is ideal for applications where a high-quality finish is required, such as retail displays, folding cartons, and packaging for consumer goods like apparel and shoes.

F-flute provides excellent printability, making it the ideal choice for businesses that require precise and sharp images on their packaging. The small flute size ensures that the packaging is lightweight and easy to handle, without compromising on strength.

| Flute Type | Height | Common Uses | Advantages |

|---|---|---|---|

| A-Flute | ~5mm | Fragile items (glassware, electronics) | Best cushioning and shock absorption |

| B-Flute | ~3mm | Retail packaging, food, cosmetics, small electronics | Balanced strength and cushioning |

| C-Flute | ~4mm | Medium-weight items (clothing, appliances) | Versatile, good stacking strength, moderate cushioning |

| E-Flute | ~1.5mm | High-quality retail packaging, luxury products | Lightweight, high strength, excellent for printing |

| F-Flute | ~1mm | Point-of-sale displays, consumer goods packaging | Compact, high printability, lightweight |

At Polyflute, we provide a range of flute sizes to meet the diverse packaging needs of our clients. Whether you require the superior cushioning of A-flute or the compact design of F-flute, we have the expertise to guide you in selecting the right corrugated flute size for your product.

The corrugated flute size you choose plays a critical role in the overall performance of your packaging. It affects several aspects, including the strength, durability, cushioning, and overall efficiency of the packaging during transit and storage. Here are some of the key ways in which flute size impacts packaging performance:

The strength of corrugated board is directly influenced by the height and structure of the flute. Larger flutes, such as A-flute, provide more cushioning and absorb shock better, making them the ideal choice for fragile products that need extra protection. These larger flutes also offer more flexibility and are well-suited to products that may be subject to heavy impacts during shipping.

Smaller flutes, like F-flute, provide higher compression strength, which is important for ensuring that the packaging maintains its shape and structure, especially when stacked on top of other boxes. Choosing the correct corrugated flute size based on the level of protection required is crucial to ensuring that your products arrive in perfect condition.

Larger flute sizes such as C-flute and A-flute tend to add more weight to the packaging, which could increase the overall shipping cost. In contrast, smaller flute sizes like E-flute and F-flute offer lightweight packaging options that reduce material costs and can help lower shipping expenses.

However, it’s important to balance the cost savings from smaller flutes with the need for adequate protection. For products that require minimal protection, smaller flute sizes may be the best option. But for fragile items that need robust cushioning, investing in a larger flute size can help avoid costly damage during transit.

When packaging products, it’s also essential to consider how well the packaging can be stacked. Smaller flute sizes like F-flute and E-flute allow for better stacking because they result in thinner, more compact packaging. This enables businesses to maximize storage and shipping space, reducing the overall volume and shipping costs.

Larger flute sizes, while offering better protection, take up more space and may not be as stackable. However, they are ideal for products that require significant cushioning or are irregularly shaped and require more volume in the packaging.

At Polyflute, we help our clients evaluate all of these factors to choose the best corrugated flute size for their specific packaging needs, ensuring optimal performance and cost-effectiveness.

Selecting the right corrugated flute size is not just about choosing the largest or smallest flute available. Several factors need to be considered to ensure that your packaging meets the necessary requirements for strength, protection, and cost-effectiveness.

The first and most important consideration is the type of product being packaged. Heavier products, or those that are more fragile, will require larger flute sizes for enhanced cushioning. Conversely, lightweight or durable items can be packaged with smaller flutes, which will provide sufficient protection without excessive cost.

Shipping conditions, including the distance the products will travel, the handling they will undergo, and the potential for rough conditions, are important factors to consider. Products that will be subjected to long-distance shipping or rough handling may require larger flute sizes to ensure that they remain protected during transport.

Environmental factors such as temperature, humidity, and exposure to moisture can also impact the performance of corrugated board. Larger flute sizes may offer better protection in harsh conditions, while smaller flutes may be more suited for controlled environments where minimal cushioning is needed.

Cost is always a factor when selecting packaging materials. Larger flute sizes will increase the cost of packaging due to the additional material used. Polyflute works closely with clients to help them select the right corrugated flute size that balances protection and cost, ensuring the most efficient packaging solution without compromising on quality.

Selecting the right corrugated flute size is essential for optimizing packaging performance. Whether you’re protecting fragile items or ensuring efficient transport, understanding how flute size impacts strength, cushioning, and weight is key to making the right choice. At Polyflute, we offer a range of flute sizes and customized solutions to meet your specific packaging needs. Contact us today to discuss how we can help you enhance your packaging strategy and improve the overall efficiency of your operations.