Polycarbonate sheets are one of the most versatile and high-performance thermoplastic materials used in both commercial and industrial applications today. Thanks to their outstanding impact resistance, exceptional transparency, and thermal stability, polycarbonate sheets have rapidly replaced traditional materials like glass and acrylic in many fields. Whether used for skylights, greenhouse glazing, machine guards, or architectural facades, these sheets offer a unique blend of strength and flexibility.

Polycarbonate is a polymer composed of bisphenol A (BPA) and phosgene. Though the name may sound complex, the resulting material is renowned for its excellent mechanical properties. For instance, it is virtually unbreakable, with up to 250 times the impact resistance of glass. Despite this strength, it is remarkably lightweight and easy to fabricate.

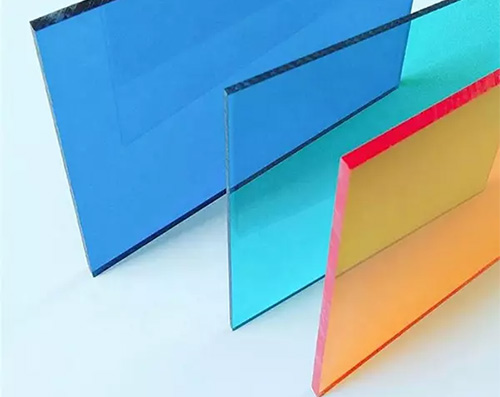

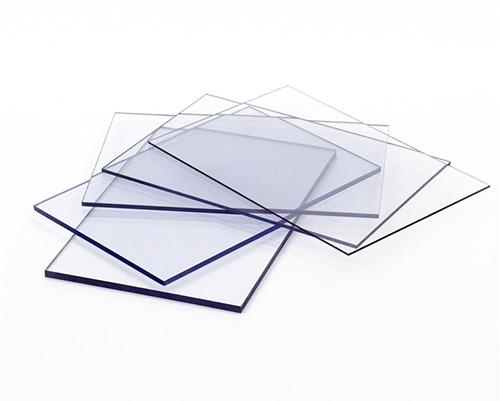

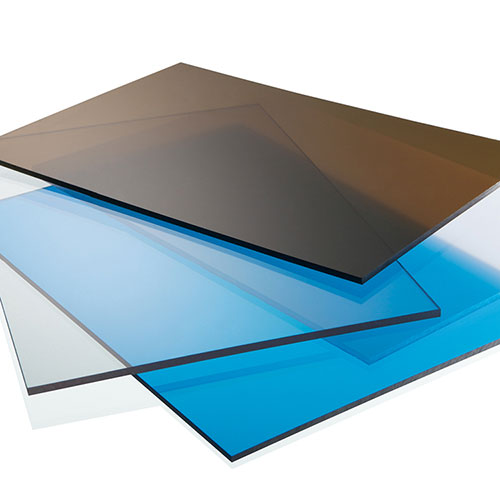

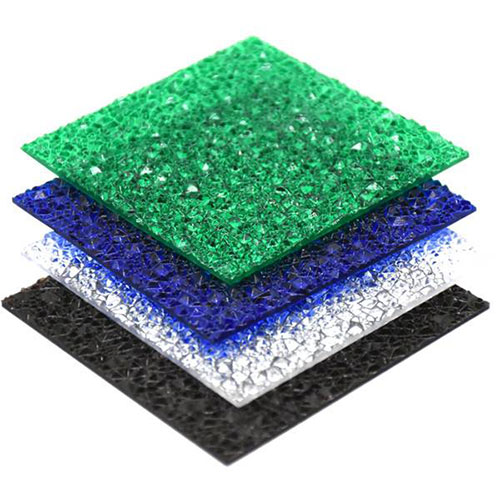

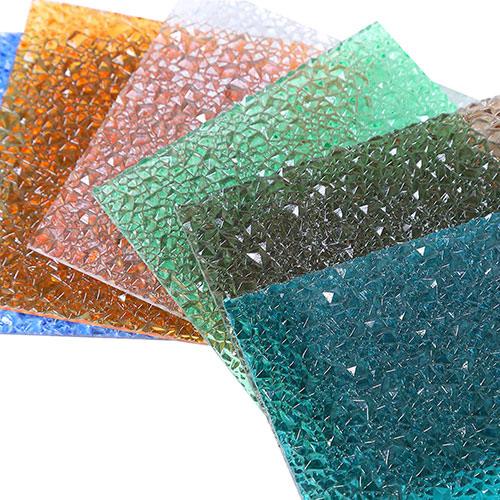

One of the major reasons for polycarbonate sheets’ popularity is their adaptability. They are available in various thicknesses, finishes, colors, and forms—including solid, multiwall, and corrugated sheets. This makes them suitable for a vast range of industries such as:

Another crucial advantage is their resistance to UV rays when coated properly. UV-coated polycarbonate sheets can withstand long-term outdoor exposure without yellowing or degrading. Additionally, they maintain transparency and structure across a wide temperature range, typically from -40°C to 120°C.

Price and size are two of the most significant factors that buyers evaluate when sourcing polycarbonate sheets. Given the diversity of applications and material variants, understanding these two elements is essential for optimal material selection and cost control. Choosing the wrong thickness or paying above market price for standard sheets can lead to unnecessary expenditures or structural inefficiencies.

This comprehensive guide will delve into standard sheet sizes, price factors, selection strategies, and supplier evaluations to help you make informed purchasing decisions for polycarbonate sheets.

When selecting polycarbonate sheets, size plays a pivotal role in both the cost-effectiveness and performance of the product. Manufacturers offer a wide range of size options to accommodate diverse application needs. In this section, we will explore the most common polycarbonate sheet sizes available on the market, along with their practical implications.

Polycarbonate sheets come in various thicknesses, typically ranging from 1mm to over 20mm. The thickness impacts not only the strength and rigidity of the material but also its price and weight. Here’s an overview of common thickness categories:

Thicker sheets generally provide better insulation, sound resistance, and load capacity but come at a higher cost.

Polycarbonate sheets are usually available in standard dimensions for easy handling and manufacturing consistency. These dimensions include:

When planning your project, it’s crucial to consider standard sizes to reduce the cost of customization and material waste. Buying standard-sized sheets often results in faster delivery and lower prices.

Weight is another important factor when selecting polycarbonate sheet sizes. Heavier sheets can be more difficult to install, especially at elevated heights or on delicate structures. Here is a general approximation of weight per square meter based on thickness (solid sheets):

Multiwall and corrugated sheets are typically lighter due to their hollow structure. For example, a 10mm twin-wall sheet weighs approximately 1.7 kg/m².

Different types of polycarbonate sheets have varying size availabilities:

Here’s a quick reference chart showing typical sheet sizes used by application:

| Application | Recommended Size | Type | Thickness (mm) |

|---|---|---|---|

| Greenhouse Roofing | 2100mm x 5800mm | Twin-wall | 6mm – 10mm |

| Residential Skylight | 1220mm x 2440mm or custom | Solid/Embossed | 4mm – 6mm |

| Safety Partition | 1220mm x 2440mm | Solid | 10mm – 12mm |

| Machine Guarding | Custom | Solid | 6mm – 20mm |

| Sound Barriers | 2050mm x 3050mm or custom | Solid | 16mm – 25mm |

| Advertising Signage | 1220mm x 2440mm | Solid/Embossed | 2mm – 4mm |

By aligning your material choices with standard sizes, you can significantly optimize both your project execution time and cost.

When evaluating the cost of polycarbonate sheets, it’s essential to understand the various elements that influence pricing. Whether you’re purchasing bulk quantities or custom sizes, the following factors will affect your overall expenditure:

The thicker the sheet, the more raw material is required—naturally driving up the cost. Similarly, solid polycarbonate sheets are generally more expensive than multiwall or corrugated types due to their density and strength.

Standard sheet sizes typically offer better value. However, customized cuts or dimensions that deviate from manufacturer defaults often come with added labor and material waste costs.

UV-resistant coatings, anti-fog layers, and anti-scratch treatments enhance performance but also raise the price. For outdoor applications, UV protection is often essential and worth the additional cost.

Well-known brands may charge a premium for reliability, quality control, and warranty coverage. Local manufacturers or lesser-known brands might offer more competitive prices, but quality should be verified.

Fluctuations in the cost of petroleum-based raw materials, transportation, and labor can affect the market price of polycarbonate sheets. Global supply chain issues or regional shortages may also cause price spikes.

Buying in larger quantities generally results in lower per-sheet pricing. Suppliers often offer bulk discounts for orders over a certain volume.

Regional pricing varies due to transportation costs, import taxes, and local supply chains. For example, polycarbonate sheets in Southeast Asia may be cheaper than in Europe due to proximity to raw material sources.

Understanding these pricing variables allows for better budgeting and supplier negotiation.

Selecting the appropriate polycarbonate sheet for your project involves considering several factors to ensure optimal performance and cost-effectiveness. Here’s a guide to help you make an informed decision:

Identify the specific needs of your project:

Assess the environmental conditions the sheets will be exposed to:

Understand the structural demands:

Balance performance with cost:

When sourcing polycarbonate sheets, it’s essential to consider reputable suppliers and compare prices to ensure value for money. Here’s an overview of some suppliers and their offerings:

When purchasing polycarbonate sheets, it’s advisable to source from specialized suppliers that offer a wide selection of sheet types, custom sizing, and reliable quality. Common types of polycarbonate sheets on the market include solid sheets, multiwall (twin-wall or honeycomb) panels, and corrugated panels. Prices typically vary based on sheet thickness, size, and functionality, ranging from as low as $10 to over $800 per sheet.

Polyflute polycarbonate panels, for example, are widely recognized for their excellent performance in applications such as greenhouses, awnings, skylights, and general construction. These panels are known for being lightweight, impact-resistant, weather-resistant, and thermally efficient. The Polyflute product range includes clear, frosted, white, and colored sheets, with thicknesses typically ranging from 4mm to 16mm to suit various structural needs. Multiwall or corrugated options are often sold in packs (e.g., 5-pack sets), starting at around $85, with prices increasing depending on specifications.

Many professional plastic sheet suppliers also provide custom cut-to-size services, allowing customers to order sheets that precisely match their project requirements. This reduces on-site cutting, minimizes material waste, and ensures faster installation. Some platforms also offer real-time online quoting tools, where customers can enter dimensions to instantly receive pricing and estimated shipping costs—making budget planning easier and more transparent.

When choosing polycarbonate sheets, it is highly recommended to opt for variants with UV protective coatings, especially for outdoor use. This feature significantly enhances the lifespan of the panels by maintaining clarity and mechanical strength even after prolonged exposure to sunlight.

Prices for polycarbonate sheets vary based on type, thickness, and size. Here’s a general comparison:

| Type | Thickness | Size (inches) | Price Range |

|---|---|---|---|

| Solid Clear Sheet | 1/4″ | 24 x 48 | $72.00 |

| Solid Clear Sheet | 1/2″ | 48 x 96 | $416.46 |

| Twinwall Panel (5-pack) | 4mm | Varies | Starting at $94.95 |

| Corrugated Panel (5-pack) | Varies | Varies | Starting at $85.00 |

Note: Prices are subject to change and may vary based on supplier and location.

Polycarbonate sheets offer a versatile solution for various applications, from construction to agriculture. Understanding the different types, sizes, and factors affecting prices is crucial for selecting the right product for your needs. By considering application requirements, environmental factors, structural demands, and budget constraints, you can make an informed decision that ensures both performance and cost-efficiency.

For the most accurate and up-to-date pricing, it’s recommended to consult directly with suppliers or use online calculators provided by retailers to obtain quotes tailored to your specific project dimensions and requirements.