For both commercial growers and home gardening enthusiasts, greenhouses are essential structures that extend growing seasons, protect plants, and create ideal microclimates. However, the performance and durability of a greenhouse depend significantly on the materials used in its construction—particularly the glazing or covering panels.

Among the many options available, two of the most popular transparent materials for greenhouse construction are acrylic and polycarbonate. Acrylic or polycarbonate for greenhouse? Each has its strengths and weaknesses, and choosing between them isn’t always straightforward.

This comprehensive guide dives deep into the acrylic or polycarbonate for greenhouse debate to help you make an informed decision. As a manufacturer specializing in plastic panel solutions, we understand the nuances behind each option. We’ll compare these materials across critical factors such as light transmission, impact resistance, durability, cost, and more.

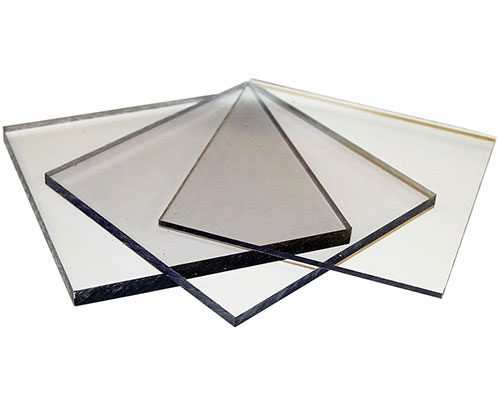

Acrylic, also known as PMMA (Polymethyl Methacrylate), is a transparent thermoplastic that’s often used as a lightweight or shatter-resistant alternative to glass. Acrylic is known for its crystal-clear transparency, UV resistance, and rigidity.

Key features of acrylic include:

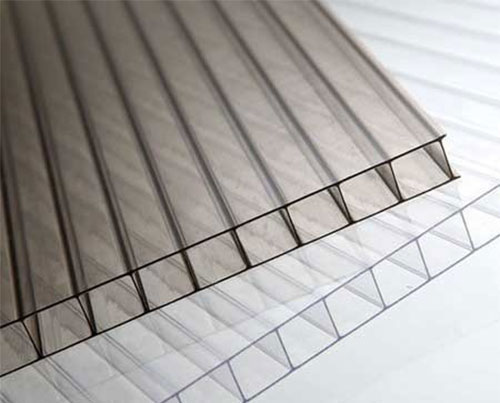

Polycarbonate is a thermoplastic polymer that is prized for its toughness and versatility. It is used widely across industries, including construction, automotive, and agriculture, due to its high impact resistance and optical properties.

Key features of polycarbonate include:

Light is arguably the most crucial factor for plant health. The glazing material must allow ample sunlight while minimizing UV damage and overheating.

Acrylic offers superior clarity, with light transmission rates as high as 92%. This makes it one of the best materials for natural light diffusion. For crops requiring abundant sunlight—like tomatoes, peppers, or citrus trees—acrylic panels ensure maximum exposure.

However, acrylic does not naturally block UV rays unless treated, and extended exposure to UV can cause yellowing over time.

Polycarbonate transmits slightly less light than acrylic, ranging from 85% to 89%, depending on thickness and design (e.g., twin-wall or multi-wall panels). However, most polycarbonate sheets come with built-in UV protective layers that prevent yellowing and provide excellent longevity.

Additionally, polycarbonate’s light diffusion is more uniform, reducing hotspots in the greenhouse and creating a more stable growing environment.

Verdict: Choose acrylic if maximum light clarity is your priority. Choose polycarbonate if you want strong light diffusion with UV protection.

Greenhouses must withstand external forces such as hail, strong winds, or even falling debris.

While acrylic is more impact-resistant than glass, it is still prone to cracking under high stress. It has about 10–20 times the impact resistance of glass but cannot match polycarbonate’s toughness. If hit hard enough, acrylic will shatter.

Polycarbonate shines when it comes to impact resistance. It is virtually unbreakable, offering 200 times the impact resistance of glass and 10–20 times that of acrylic. This makes polycarbonate ideal for greenhouses in storm-prone areas or those subject to heavy snowfall or hail.

Verdict: Polycarbonate is the clear winner for durability and impact resistance.

Greenhouses must retain warmth to support year-round growth. The choice of material can affect the structure’s energy efficiency.

Single-layer acrylic sheets provide modest insulation. While thicker panels can improve thermal performance, they may not compete well with polycarbonate’s multi-wall structures.

Polycarbonate is available in twin-wall, triple-wall, and even five-wall formats, creating air pockets between layers that act as thermal barriers. These configurations dramatically reduce heat loss and maintain internal temperatures more efficiently.

Verdict: Polycarbonate offers superior insulation, especially in multi-wall configurations.

Acrylic is significantly lighter than glass, making it easier to transport and install. However, it is still more rigid than polycarbonate and can crack if handled roughly.

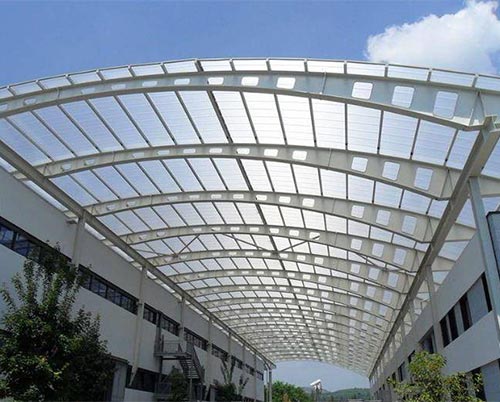

Polycarbonate is extremely lightweight and more flexible than acrylic, allowing for easier bending and shaping. This is ideal for curved greenhouse roofs or customized designs.

Verdict: Polycarbonate is more user-friendly for installation and complex greenhouse structures.

High-quality acrylic can last 10–15 years or more, especially if UV-treated. However, untreated acrylic may yellow and degrade under prolonged sun exposure.

Polycarbonate panels with UV protection can last 10–20 years without yellowing or cracking. However, UV coatings must be properly applied and maintained to ensure longevity.

Verdict: Both materials are long-lasting, but polycarbonate with UV treatment has the edge in long-term outdoor use.

Acrylic panels are generally more affordable upfront. For hobbyists or small greenhouses, this makes acrylic an attractive choice, especially where impact resistance isn’t critical.

Though polycarbonate is more expensive initially, its superior strength, insulation, and resistance to damage often lead to lower maintenance and replacement costs over time.

Verdict: For short-term or small-scale use, acrylic might be sufficient. For long-term durability, polycarbonate offers better value.

| Greenhouse Type | Recommended Material | Reason |

|---|---|---|

| Hobby/Backyard | Acrylic or Polycarbonate | Acrylic for clarity; Polycarbonate for safety |

| Commercial Growing | Polycarbonate | Strength, insulation, long lifespan |

| Educational Greenhouses | Acrylic | Visibility for educational purposes |

| High Altitude / Windy Areas | Polycarbonate | High impact resistance |

Polycarbonate and acrylic are both recyclable plastics. However, the environmental impact of production and disposal should be considered.

Greenhouse operators committed to sustainability may consider post-consumer recycled options or select manufacturers who use environmentally friendly processes.

As a trusted manufacturer of plastic solutions for greenhouse applications, we offer both acrylic and polycarbonate panel systems customized to your project needs. Whether you’re building a small backyard greenhouse or a commercial-scale horticultural facility, our products ensure durability, clarity, and performance.

Our engineering team can advise you on the best material selection based on:

Polyflute is one of our premium polycarbonate brands, known for its multi-wall panel designs and superior weather resistance. While we offer this as part of our range, we tailor every order to meet your unique requirements.

Q1: Can I use both materials in one greenhouse?

Yes! Some growers use acrylic for walls (for clear visibility) and polycarbonate for roofing (for durability).

Q2: Which material is easier to clean?

Both are easy to clean with mild soap and water. Avoid abrasive cloths that may scratch the surface.

Q3: How do I prevent yellowing?

Choose UV-treated panels and make sure they are installed with the UV-coated side facing out.

Q4: What thickness should I choose?

The decision between acrylic and polycarbonate for your greenhouse depends on your unique goals and constraints. Here’s a quick recap:

| Feature | Acrylic | Polycarbonate |

|---|---|---|

| Light Transmission | ★★★★★ | ★★★★☆ |

| Impact Resistance | ★★☆☆☆ | ★★★★★ |

| Thermal Insulation | ★★★☆☆ | ★★★★★ |

| UV Resistance | ★★★★☆ | ★★★★★ |

| Flexibility | ★★☆☆☆ | ★★★★★ |

| Cost | ★★★★☆ | ★★★☆☆ |

For growers seeking maximum clarity and affordability in gentle climates, acrylic sheet is a solid option. For those prioritizing toughness, insulation, and long-term value, polycarbonate is the clear winner.

As a professional manufacturer of greenhouse panel systems, we are here to support you in finding the perfect material solution that balances performance, aesthetics, and cost-effectiveness. Welcome to contact us right now!