In modern logistics, manufacturing, and packaging industries, Plastic Partition Boards have become an essential solution for safe and efficient product handling. Known for their durability, flexibility, and environmental benefits, these boards—also referred to as corrugated plastic partitions—have transformed how goods are stored, transported, and protected.

In this in-depth guide, follow Polyflute to explore everything you need to know about Plastic Partition Boards: what they are, how they’re made, where they’re used, their benefits, and how to select the right type for your business needs.

Plastic Partition Boards are rigid yet lightweight sheets made from corrugated polypropylene or polyethylene plastic. These boards are structured like corrugated cardboard but made of plastic, offering increased strength, moisture resistance, and reusability.

The core structure—similar to fluted layers in cardboard—gives the partition board its strength and flexibility. The surface layers protect the core, allowing it to withstand impacts, vibration, and exposure to chemicals or water.

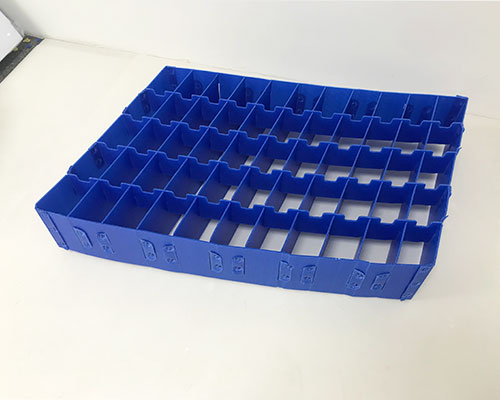

Also known as corrugated plastic partitions, these boards are frequently used as dividers within boxes, totes, and containers to separate individual items, prevent scratching, and facilitate neat organization during storage or transit.

Whether you run a manufacturing facility or a packaging warehouse, integrating Plastic Partition Boards can dramatically improve your operational efficiency. Here are some compelling reasons:

One of the primary uses of Plastic Partition Boards is to protect fragile items—such as glass bottles, electronics, automotive components, or pharmaceutical vials—by preventing direct contact with one another. The partitions absorb shocks and vibration, reducing damage rates during transport.

Unlike cardboard partitions that degrade quickly, corrugated plastic partitions can be reused hundreds of times. They are resistant to moisture, grease, oil, and most chemicals. This makes them ideal for supply chains seeking sustainable, long-term packaging solutions.

While the upfront cost of Plastic Partition Boards is higher than paper-based alternatives, their reusability significantly lowers the total cost of ownership. Many companies report a return on investment within a few months due to reduced damage claims and fewer packaging replacements.

These kinds of boards are available in multiple structural formats and functional designs to suit various industrial and commercial packaging applications. Choosing the right type depends on the product’s size, fragility, stacking requirements, and handling frequency. Below is a table that outlines the most commonly used types of Plastic Partition Boards:

| Type | Description | Typical Applications |

|---|---|---|

| Cross-insert Partitions | Two sets of slotted plastic sheets interlock to form a grid, creating uniform cells without adhesive. | Glass bottles, vials, cosmetics, small jars |

| Custom Cell Trays | Each cell is custom-cut to tightly fit one product, offering high precision and protection. | Automotive parts, electronics, instruments |

| Layer Pads / Flat Dividers | Flat corrugated plastic sheets placed between product layers or pallets to prevent friction/damage. | Warehouse palletizing, stacking layers of goods |

| Foam-lined Partitions | Partitions lined with PE or EVA foam to provide cushioning and reduce impact shock. | Delicate components like camera lenses, sensors |

| Anti-static/ESD Partitions | Made from conductive or anti-static materials to protect electronics from static discharge. | PCBs, semiconductors, sensors, control boards |

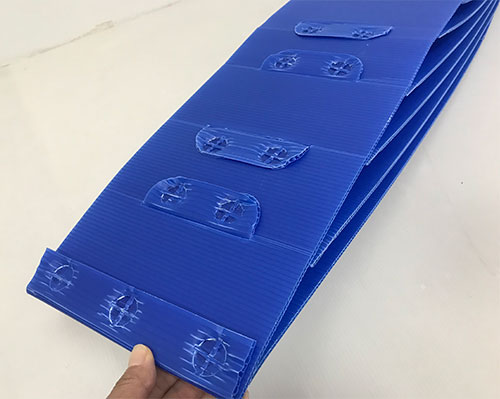

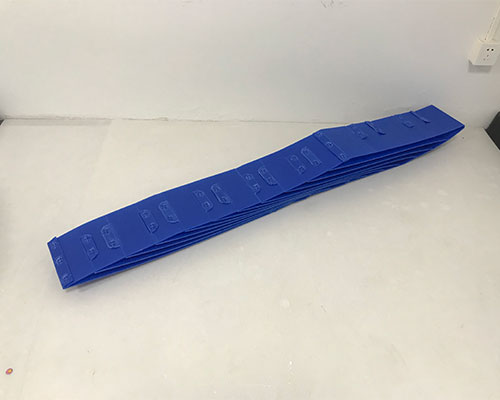

| Foldable Partition Sets | Designed to be collapsible when not in use, saving space in return logistics or storage. | Returnable packaging, reusable bins |

| Food-grade Sanitary Partitions | Made from virgin PP materials, easy to clean and compliant with food safety standards. | Meat processing, dairy transport, beverage bottling |

| Heavy-duty Reinforced Partitions | Thicker or rib-reinforced partitions for large or heavy items; impact- and crush-resistant. | Mechanical parts, industrial tools |

Each of these corrugated plastic partitions can be customized in terms of size, color, thickness (usually 2mm–10mm), and functional coating (UV-resistant, fire-retardant, etc.). By choosing the right type, businesses can enhance protection, improve loading efficiency, and reduce material waste across their logistics processes.

Plastic Partition Boards are used across various industries. Here’s how different sectors apply them:

Car manufacturers and suppliers use plastic partitions to separate engine parts, lights, trims, and other delicate components in bins or crates. The lightweight design allows for easy stacking and transport on assembly lines.

In tech and electronics, protection against static electricity and mechanical shock is critical. Plastic Partition Boards can be manufactured with anti-static or conductive properties to protect circuit boards, chips, and sensors.

Pharmaceuticals and lab equipment are sensitive to contamination and breakage. Corrugated plastic partitions provide sterile, washable barriers that ensure safe delivery of vials, test tubes, and instruments.

Bottled drinks, canned goods, and perishable items benefit from clean, non-toxic plastic partitions that are easy to sanitize and resistant to moisture.

Warehouses use Plastic Partition Boards in custom containers to keep parts organized, reduce handling time, and improve inventory accuracy.

Let’s break down the core advantages that make Plastic Partition Boards a superior choice compared to alternatives.

The fluted internal structure provides excellent strength-to-weight ratio, reducing transportation costs and physical strain during manual handling.

Unlike paper or wood, Plastic Partition Boards are fully waterproof and resistant to oils and most industrial chemicals.

Whether you need narrow channels for batteries or wide slots for auto parts, plastic partitions can be custom-cut to your product’s dimensions. They’re easy to fabricate with die-cutting, CNC routing, or hot-welding.

Sanitization is simple. A quick wipe with water or disinfectant makes them ready for reuse, ideal for food-grade or sterile environments.

Many manufacturers now offer Plastic Partition Boards made with recycled polypropylene, and the boards themselves are recyclable at end-of-life.

Most Plastic Partition Boards are made from high-quality materials designed to meet different durability, flexibility, and safety requirements.

Surface Finishes and Add-ons:

These material options and finishes enable customization of corrugated plastic partitions to fit diverse industry needs, improving product protection and lifecycle sustainability.

Depending on your needs, Plastic Partition Boards can be tailored in many ways:

| Custom Feature | Description |

|---|---|

| Size & Thickness | From 2mm to 10mm, depending on strength needed |

| Number of Cells | Can be customized to fit exact product counts |

| Print & Labels | Company logos, instructions, or barcodes |

| Color Options | Blue, black, white, gray, green, etc. |

| Add Foam Lining | For sensitive products |

| Edge Banding | To protect edges and improve appearance |

| Feature | Plastic Partition Boards | Cardboard | Wood |

|---|---|---|---|

| Reusability | ✅ High | ❌ Low | ❌ Moderate |

| Water Resistance | ✅ Excellent | ❌ Poor | ❌ Moderate |

| Cleanability | ✅ Easy | ❌ Difficult | ❌ Moderate |

| Weight | ✅ Light | ✅ Light | ❌ Heavy |

| Cost per Use | ✅ Low | ✅ Low (short-term) | ❌ High |

Clearly, Plastic Partition Boards outperform traditional materials in most categories, especially in long-term use scenarios.

When selecting Plastic Partition Boards, consider the following important factors to ensure optimal protection and cost efficiency:

If you’re unsure about the best choice, always consult a reliable manufacturer with expertise in corrugated plastic partitions. They can prototype and test sample configurations tailored to your product requirements before committing to mass production, ensuring the solution meets both performance and budget goals.

The global market for corrugated plastic partitions and Plastic Partition Boards is expected to grow significantly due to:

Eco-conscious companies are also switching from single-use cardboard to reusable partition boards to meet sustainability goals.

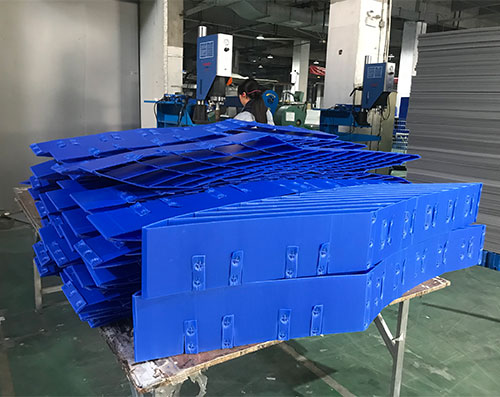

We are a professional manufacturer specializing in corrugated plastic partitions for over a decade. Our solutions are trusted by clients across automotive, electronics, and pharmaceutical industries. We offer:

Whether you need small-lot custom jobs or bulk industrial orders, we can deliver durable and cost-effective corrugated plastic partitions that meet your exact needs.

Plastic Partition Boards are a modern, versatile, and environmentally friendly solution for product protection and space optimization. From fragile electronics to industrial hardware, they offer superior performance, longevity, and adaptability.

By choosing the right corrugated plastic partitions, you not only protect your products better but also streamline your logistics and reduce waste. Whether you’re a factory manager, warehouse operator, or packaging buyer, upgrading to Plastic Partition Boards is a smart investment.

Ready to optimize your packaging? Contact us today to request a sample or a custom quote about the plastic partition boards. We look forward to being your reliable partner in protective packaging solutions.