Efficient fruit harvesting in commercial orchards depends on the right tools—orchard picking bins being one of the most critical. Whether you’re cultivating apples, oranges, peaches, or plums, a well-designed picking bin enhances productivity, protects produce, and reduces overall handling costs. Among the many materials used for making these bins, polypropylene (PP) stands out as a top choice.

In this comprehensive guide, we’ll explore everything about orchard picking bins—from materials and design to applications and customization options. We’ll also cover what to look for in a reliable orchard picking bins manufacturer and how custom orchard picking bins can make a difference for your business.

Fruit harvesting is a delicate operation. The wrong bins can bruise soft fruits, fail under heavy loads, or require frequent replacement. Here’s why orchard picking bins are essential:

High-quality orchard picking bins serve not only as containers but also as critical tools in a high-volume agricultural workflow.

Among plastic materials used in bin manufacturing—like HDPE, ABS, and PVC—PP (polypropylene) is gaining popularity due to its versatility and excellent performance in outdoor, agricultural settings. Its balance of strength, weight, and resistance to environmental stress makes it ideal for demanding harvest conditions.

| Feature | Benefit |

|---|---|

| Lightweight | Easier to carry, reduces strain for workers |

| High tensile strength | Withstands impacts, heavy loads without cracking |

| Chemical resistance | Durable against fertilizers, soil acids, and detergents |

| UV stabilization | Prolonged outdoor use without degradation |

| Food-safe | Non-toxic and compliant with food handling regulations |

| Recyclable | Environmentally friendly and sustainable |

PP orchard picking bins are an investment that pays off across multiple harvests due to their durability, reusability, and cost-effectiveness. They require minimal maintenance, maintain structural integrity over time, and support hygienic standards essential for fresh produce handling—making them a smart choice for modern fruit growers.

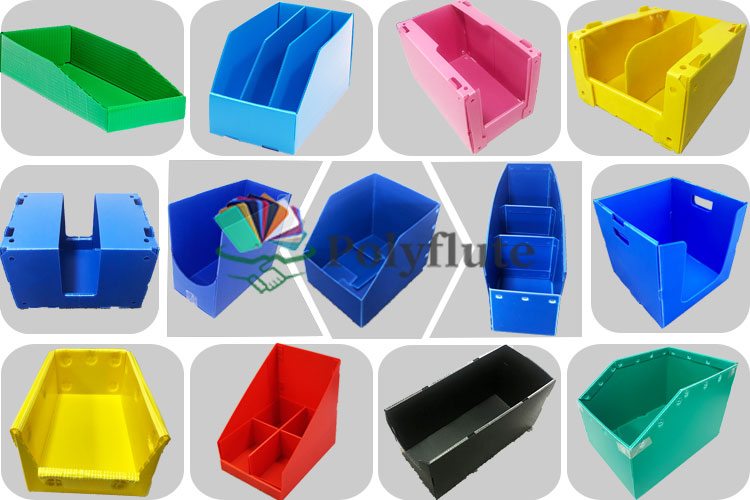

Polypropylene (PP) orchard picking bins come in various shapes and capacities to support different harvest scenarios—from small, manual fruit picking to large-scale mechanized operations. Below are the most common types used across orchards, along with their specifications in terms of size, structure, and color customization.

These small, lightweight baskets are perfect for delicate fruits such as apricots, cherries, and figs. Handheld bins are designed for convenience and to prevent bruising during the picking process.

These bins are easy to clean and sanitize, making them suitable for frequent reuse, especially in organic or specialty fruit farms.

These bins are widely used in orchards that grow apples, oranges, lemons, and similar-sized fruits. They are ideal for both manual harvesting and small-scale tractor collection systems.

These bins strike a balance between capacity and manageability, making them popular for daily harvest routines in small-to-mid-sized orchards.

Macro bins, also called pallet bins, are designed for large-volume harvesting operations that require forklift compatibility. They’re commonly used for fruits like peaches, nectarines, and pears.

These bins are ideal for transporting fruit directly to packing lines or cold storage facilities and are built to handle heavy loads without deformation.

Collapsible PP bins offer the flexibility of high-volume use during harvest season and compact storage afterward, making them perfect for seasonal operations.

These bins reduce off-season storage needs significantly and are a preferred choice for exporters and large-scale packing operations.

Standard bins don’t always suit every orchard. That’s why many growers turn to custom orchard picking bins manufacturers to develop solutions that match their workflows.

| Category | Custom Features |

|---|---|

| Size | From 10L handheld to 650L bulk bins |

| Color | Color-coded bins by fruit variety or orchard zone |

| Branding | Company logos, labels, QR codes for inventory tracking |

| Ventilation | Variable hole patterns for airflow & drainage |

| Shape & Handles | Ergonomic handles, reinforced edges, nesting options |

| Lids & Covers | Optional lids for protection during transport |

Partnering with a reliable orchard picking bins manufacturer allows you to design bins that improve worker efficiency and protect your harvest under real-world conditions.

These bins are found in nearly every segment of the fruit production and supply chain:

In all these stages, PP orchard picking bins offer cleanliness, food safety, and stackability that paper cartons or wooden crates can’t match.

When selecting the ideal orchard picking bin for your operation, multiple factors should be weighed carefully to ensure optimal efficiency, product safety, and return on investment.

For high-volume operations, stackable or collapsible bins streamline logistics and storage. Meanwhile, boutique or organic growers may benefit from bins with custom dimensions, brand printing, or unique colors to enhance traceability and market presentation. Choosing the right bin type helps optimize harvest workflow, reduce waste, and protect your fruit from field to shelf.

Finding the right orchard picking bins manufacturer is critical for ensuring consistent quality, timely delivery, and cost-effective solutions.

A professional manufacturer can also provide after-sales support, documentation for food safety, and logistics coordination—particularly important for international buyers.

PP orchard bins are not only efficient but also contribute to long-term sustainability:

While initial costs might be higher than cardboard or wood, PP bins pay off by reducing fruit damage, minimizing waste, and lasting several harvest cycles.

A mid-sized citrus farm in South Australia partnered with a custom orchard picking bins supplier to develop a lightweight, stackable PP bin tailored for oranges. They:

This case underscores how investing in the right bin type can create real economic and operational gains.

As orchard operations scale and modernize, investing in the right harvesting tools becomes vital. Orchard picking bins made from polypropylene (PP) offer a robust, hygienic, and sustainable solution for fruit growers of all sizes.

From handheld baskets to macro bulk bins, the variety and customization potential ensure that every farm can find or design bins that improve efficiency and fruit quality. Working with a trusted orchard picking bins manufacturer enables your business to take full control of its harvest process.

Whether you’re seeking standard sizes or looking for custom orchard picking bins, PP bins offer the reliability and performance needed to thrive in competitive produce markets.

Looking for high-quality PP orchard picking bins tailored to your fruit and workflow? Partner with a trusted orchard picking bins manufacturer today to explore customizable solutions that match your harvest goals.

📩 Contact us now for catalogs, samples, and bulk pricing for custom orchard picking bins!