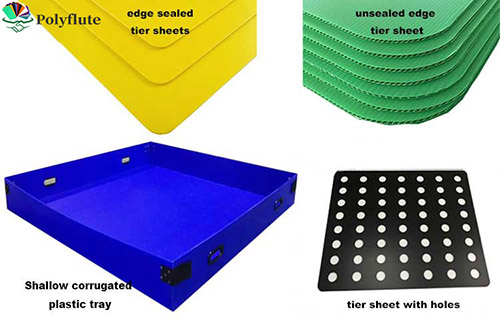

Types of Plastic Layer Pads

Choosing the right type of plastic layer pad is essential to optimize your palletizing process, protect your goods, and ensure smooth transportation and storage. Below are the most commonly used types of plastic layer pads and their specific features:

1. Corrugated Plastic Layer Pads

Corrugated plastic layer pads are constructed using a fluted core sandwiched between two flat plastic surfaces. This design creates a lightweight structure that still offers significant strength and cushioning. These pads are especially beneficial when shock absorption is required during shipping, making them a preferred choice for fragile or irregularly shaped products. The air gaps within the corrugated core also help reduce material usage without compromising structural integrity, making them an environmentally conscious choice.

2. Solid Plastic Layer Pads

Solid plastic layer pads are made from a continuous sheet of high-density plastic, typically polyethylene (PE) or polypropylene (PP). They provide exceptional durability and load-bearing capacity, making them suitable for heavy items, long-term storage, and demanding industrial environments. Unlike corrugated pads, solid plastic pads offer a smooth surface that resists puncture, bending, and moisture absorption. These pads are often used in industries such as automotive, heavy machinery, and bulk material handling.

3. PP Layer Pads

Polypropylene (PP) layer pads are valued for their combination of strength, chemical resistance, and flexibility. These pads are lightweight, corrosion-resistant, and can withstand exposure to oils, acids, and bases, making them suitable for chemical, pharmaceutical, and food applications. PP layer pads also maintain their performance under a wide range of temperatures, making them ideal for both refrigerated storage and outdoor shipping conditions.

4. Custom-Engineered Layer Pads

For operations with unique requirements, custom-engineered plastic layer pads are the best solution. These can be tailored in terms of dimensions, thickness, surface textures (anti-slip or glossy), and specialized properties such as anti-static performance (for electronics), food-safe materials (for consumables), or UV resistance (for outdoor use). Custom pads ensure maximum compatibility with specific products or pallet configurations and can significantly enhance handling efficiency.

Standard Specifications Comparison

| Type | Material | Strength | Weight | Common Uses | Available Sizes (mm) | Color Options |

|---|---|---|---|---|---|---|

| Corrugated Plastic Pads | PP/PE Fluted | Medium | Light | Retail, fragile goods, exports | 1000×1200, 800×1200, custom | Blue, Black, Grey, White |

| Solid Plastic Pads | Solid PP/PE | High | Heavy | Automotive, industrial parts, machinery | 1000×1200, custom | Black, Grey, White |

| PP Layer Pads | Polypropylene | Medium-High | Light-Medium | Chemicals, food, pharma, electronics | 800×1000, 1100×1300, custom | Black, Blue, Transparent |

| Custom Layer Pads | Varies | Varies | Varies | Special applications | Fully customizable | Any (Pantone available) |

Plastic layer pads come in a wide range of thicknesses, generally between 2mm to 10mm, depending on the material and load requirements. Thicker pads are more rigid and suitable for heavy-duty stacking, while thinner pads work well for light goods and more frequent reuse cycles. Color coding is also common in many operations, allowing for quick identification of product types, destinations, or batch numbers.

In addition, many pads can be manufactured with rounded corners, grip textures, or cut-out handles to meet ergonomic and operational safety requirements. These customization options ensure that plastic layer pads serve more than just a separation purpose—they become a key component in improving supply chain performance and worker productivity.

Applications Across Industries

Plastic layer pads are widely adopted across a range of industries due to their durability, hygienic properties, and ability to be customized. From food safety to high-tech logistics, these pads play an essential role in protecting goods during transit, enhancing stacking efficiency, and maintaining product integrity.

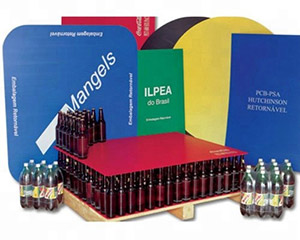

Food and Beverage Industry

In the food and beverage sector, where cleanliness and protection from contamination are critical, plastic layer pads are invaluable. They are frequently used to separate layers of bottled water, soft drinks, canned goods, and dairy products on pallets. The non-porous nature of materials like polypropylene (PP) ensures that the pads do not absorb moisture or harbor bacteria. This makes them especially suitable for cold storage and refrigerated transport. In addition, their smooth surfaces are easy to clean and can be sanitized for repeated use, aligning with food-grade handling protocols.

Pharmaceuticals

Pharmaceutical warehouses and distribution centers must maintain strict compliance with health and safety regulations. Plastic layer pads offer a hygienic solution for segregating blister packs, bottled medicine, and medical devices. Since these pads are resistant to both chemicals and biological contaminants, they can be sanitized with alcohol-based cleaners or steam without degradation. Anti-bacterial and anti-static coatings can also be added for sensitive materials, further protecting high-value pharmaceutical products during distribution.

Electronics

Electronic goods such as circuit boards, smartphone components, hard drives, and microchips are vulnerable to static discharge and mechanical damage. For these applications, anti-static corrugated plastic layer pads are often employed. These pads not only prevent layer-to-layer contact that can scratch or compress components, but they also dissipate static electricity, reducing the risk of failure caused by electrostatic discharge (ESD). Their lightweight yet rigid structure ensures delicate parts are stabilized during international shipping or warehouse sorting.

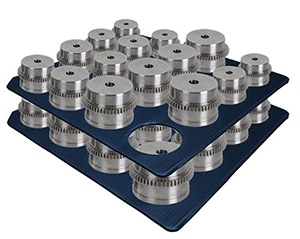

Automotive Industry

Automotive logistics deal with a diverse range of parts—from glass panels and mirrors to electrical control units and engine components. Plastic layer pads provide crucial separation to prevent metal-on-metal contact, which can cause scratches, rusting, or impact damage. Heavy-duty solid plastic pads or custom-molded PP pads are often selected for this sector. Their ability to withstand substantial weight without warping makes them ideal for stacking heavy auto parts over long distances or under rugged conditions.

Industry Applications and Pad Types

| Industry | Typical Products Handled | Recommended Pad Type | Special Features |

|---|---|---|---|

| Food & Beverage | Bottles, cans, dairy packs | Corrugated plastic layer pads | Moisture-resistant, food-safe, easy to clean |

| Pharmaceuticals | Medicines, vials, medical devices | Solid PP pads or anti-bacterial pads | Sterilizable, hygienic, chemical-resistant |

| Electronics | Microchips, circuit boards, drives | Anti-static corrugated layer pads | ESD protection, lightweight, non-abrasive |

| Automotive | Windshields, ECUs, batteries, components | Heavy-duty solid plastic layer pads | Load-bearing, scratch-resistant, reusable |

| Retail & E-commerce | Packaged goods, apparel, boxed electronics | Lightweight corrugated or custom pads | Custom colors, size-coded, printable |

By matching the right type of plastic layer pad with the demands of the specific industry, businesses can enhance protection, streamline logistics, and ensure product integrity from factory to end-user. Whether it’s ensuring pharmaceuticals remain sterile or electronics are delivered damage-free, plastic layer pads prove their value time and time again across various sectors.