In the fast-paced world of warehousing and logistics, efficiency and organization are paramount. One of the most effective ways to achieve this is through the implementation of picking bins storage solutions. These systems not only streamline the picking process but also optimize space utilization, reduce errors, and enhance overall productivity. In this comprehensive guide, we’ll delve into the various aspects of picking bins storage solutions, exploring their types, benefits, best practices, and how to choose the right system for your warehouse needs.

Picking bins storage solutions refer to organized systems that utilize bins or containers to store and manage inventory within a warehouse. These bins are designed to facilitate easy access to products, streamline the picking process, and maintain an organized storage environment. By categorizing and storing items in designated bins, warehouses can significantly reduce the time spent locating products, thereby increasing efficiency and accuracy in order fulfillment.

Selecting the appropriate type of picking bin is crucial for optimizing storage and retrieval processes. Different types of bins serve specific purposes depending on the size, weight, frequency of use, and storage conditions of the products they hold. Implementing the right mix of picking bins can significantly improve space efficiency, picking accuracy, and workflow in a warehouse environment.

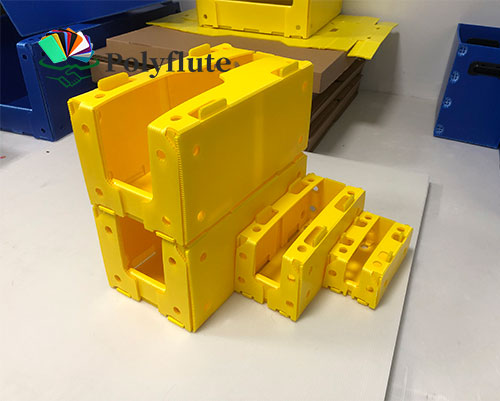

These bins are designed to stack securely on top of each other without collapsing or shifting. They help maximize vertical space, particularly in facilities where horizontal space is limited. Stackable bins are commonly used for storing uniform, high-volume items such as packaged goods, fasteners, or electronic parts. Many come with reinforced corners and interlocking features for stability during stacking, even on mobile carts or pallet racks.

Nestable bins are ideal for saving space when not in use. They are designed to fit inside one another when empty, significantly reducing the footprint during return logistics or off-season storage. These bins are especially useful in distribution centers with fluctuating inventory or seasonal operations, offering flexibility without compromising durability.

Shelf bins are narrow, open-top containers made to fit within standard racking or shelving systems. They are perfect for storing smaller items like tools, components, or pharmaceutical units. Often used with dividers, they support SKU separation and inventory organization, improving visibility and access. Their compatibility with barcode labeling systems also makes them ideal for operations with warehouse management systems (WMS).

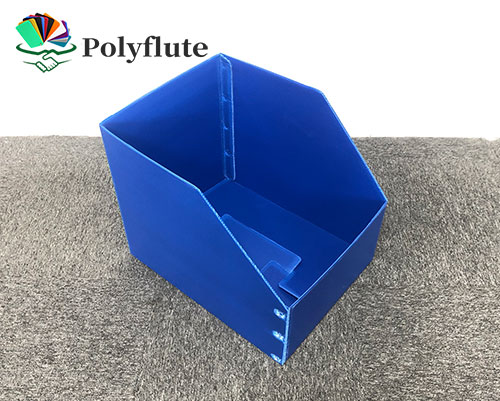

Hopper bins feature an open front design, allowing workers to reach in and grab items without removing the bin from the shelf. These are commonly used for high-turnover products or in pick-and-pack zones. Hopper bins often come with label holders and can be color-coded for faster identification. They may also be stackable when the open-front face is slightly angled or recessed.

When standard options don’t fit the warehouse needs, custom bins provide tailored solutions. These can be manufactured in specific sizes, shapes, colors, and materials to fit into automated systems, conveyors, or unique shelving arrangements. Industries like aerospace, healthcare, and automotive often rely on custom bins to store oddly shaped or high-value items securely.

| Bin Type | Space Efficiency | Ideal Use Case | Accessibility | Customizability |

|---|---|---|---|---|

| Stackable Bins | High (vertical use) | Uniform, bulky items | Moderate | Medium |

| Nestable Bins | Very High (when empty) | Seasonal or fluctuating inventory | Moderate | Medium |

| Shelf Bins | High (horizontal use) | Small items with multiple SKUs | High | High (dividers etc.) |

| Hopper Bins | Medium | High-turnover, hand-picked goods | Very High | Medium |

| Custom Bins | Depends on design | Irregular or specialized items | High | Very High |

Implementing picking bins storage solutions offers numerous advantages:

By assigning specific bins to particular products or categories, warehouses can maintain a structured and orderly environment, reducing clutter and confusion.rapidracking.com

Organized bins enable faster picking times, as workers can quickly locate and retrieve items, leading to improved productivity and throughput.

Clearly labeled and designated bins minimize the risk of picking mistakes, ensuring accurate order fulfillment and higher customer satisfaction.

Utilizing stackable or nestable bins allows for better use of vertical and horizontal space, maximizing storage capacity within the warehouse.

With a variety of bin types and configurations available, warehouses can adapt their storage solutions to meet changing inventory demands and operational requirements.

To fully leverage the benefits of picking bins storage solutions, consider the following best practices:

Evaluate your inventory characteristics, picking frequency, and storage space to determine the most suitable bin types and configurations for your operations.

Using uniform bin sizes simplifies shelving arrangements and facilitates easier stacking and nesting, contributing to a more organized storage system.

Label each bin with product information, barcodes, or color codes to enhance visibility and streamline the picking process.

Ensure that warehouse personnel are trained in the proper use and maintenance of picking bins, including correct stacking, nesting, and handling procedures.

Periodically assess your picking bins storage solutions to identify areas for improvement, accommodate changes in inventory, and implement necessary adjustments.

Selecting the appropriate picking bins storage solutions is critical for improving warehouse efficiency, reducing pick times, and ensuring better inventory management. A poor choice can lead to wasted space, damaged goods, or disrupted workflows. Below are the essential factors to evaluate when choosing the right bins:

Picking bins are typically available in plastic, metal, or cardboard. Plastic bins are the most common due to their balance of durability, cost, and versatility. They resist moisture, are lightweight, and can be used in both ambient and refrigerated environments. Metal bins, while more expensive, are ideal for industrial applications where heavy loads or sharp parts are involved. Cardboard bins, though not long-lasting, are cost-effective for temporary or seasonal use and are easily recyclable, making them suitable for sustainability-focused businesses.

Choosing the right size ensures optimal space utilization. Bins that are too large waste valuable shelf or rack space, while bins that are too small may overflow or become unstable. It’s important to match the internal dimensions to your SKU dimensions and calculate maximum load weight to avoid overloading. Overfilled bins can lead to product damage or workplace injuries.

Your picking bins should integrate smoothly with your existing storage systems, whether that includes fixed shelving, pallet racks, or automated conveyor systems. Mismatched dimensions can hinder efficiency and even damage infrastructure. Ensure bins align with your vertical lift modules, carousels, or other material handling technologies for seamless picking operations.

Bins designed for easy access significantly improve pick times. Consider open-front bins, hopper bins, or bins with transparent sides for quick visual identification. For items with high pick frequency, accessibility is paramount, especially in fast-paced fulfillment centers or retail distribution hubs.

Custom picking bins offer tailored solutions when standard models fall short. Options include custom dimensions, stacking features, anti-static properties, and even color coding for zone-based picking strategies. This level of customization is especially useful in niche industries like pharmaceuticals, electronics, and automotive, where bin design directly impacts productivity and compliance.

By carefully considering these five factors, warehouses can implement picking bins storage solutions that are not only functional but also scalable and adaptable to long-term operational needs.

Modern warehouses are increasingly integrating technology with picking bins to further enhance efficiency:

Attaching barcodes or RFID tags to bins enables real-time tracking of inventory, streamlines the picking process, and reduces errors.

Integrating bins with a WMS allows for optimized inventory management, automated replenishment, and improved order accuracy.

Incorporating bins into AS/RS setups facilitates high-density storage and rapid retrieval, significantly boosting warehouse throughput.

An e-commerce company implemented stackable plastic bins with barcode labels, integrated with their WMS. This resulted in a 30% reduction in picking times and a 20% decrease in order errors.

A distributor of automotive parts adopted custom-sized shelf bins to accommodate various components. The reorganization led to a 25% increase in storage capacity and improved inventory visibility.

Sustainability is a growing concern in warehouse operations. Opting for eco-friendly picking bins made from recycled or recyclable materials can reduce environmental impact. Additionally, durable bins that withstand repeated use minimize waste and contribute to long-term cost savings.

Implementing effective picking bins storage solutions is essential for optimizing warehouse operations, enhancing efficiency, and maintaining organized inventory management. By understanding the various types of bins, their benefits, and best practices for implementation, businesses can tailor their storage systems to meet specific needs and adapt to evolving demands. Embracing technological integrations and considering environmental impacts further solidify the role of picking bins as a cornerstone of modern warehouse efficiency.

For high-quality picking bins and corrugated plastic sheets tailored to your warehouse needs, consider exploring the offerings from Polyflute, a leading manufacturer committed to providing innovative storage solutions.