In today’s logistics and warehousing industries, protecting goods during storage and transport is crucial. One of the essential yet often overlooked components in palletizing is the plastic layer pads for pallets. These pads play a significant role in ensuring product safety, improving stacking stability, and enhancing operational efficiency. This comprehensive guide explores everything you need to know about plastic layer pads for pallets, their types, benefits, applications, and tips on choosing the right one for your business needs.

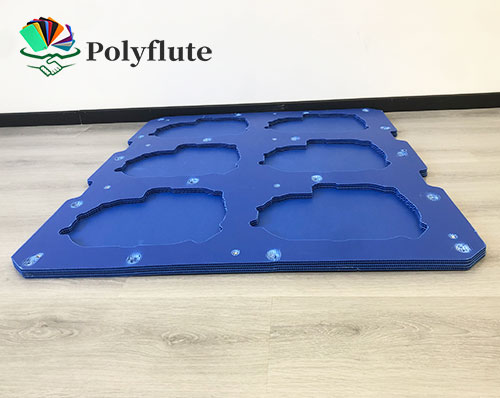

Plastic layer pads for pallets are flat sheets or pads placed between layers of goods on a pallet. Their primary purpose is to provide a stable, non-slip surface that prevents items from shifting or damaging each other during handling and transportation. Unlike cardboard or paperboard alternatives, plastic layer pads offer superior durability, moisture resistance, and reusability, making them ideal for various industries.

Using plastic layer pads for pallets delivers several advantages that improve palletizing and logistics:

There are various types of plastic layer pads tailored to different palletizing requirements. Choosing the right type ensures better load protection, cost efficiency, and suitability for your specific application.

| Type | Description | Typical Applications |

|---|---|---|

| Solid Plastic Pads | Thick, rigid sheets offering high load support | Heavy machinery, electronics |

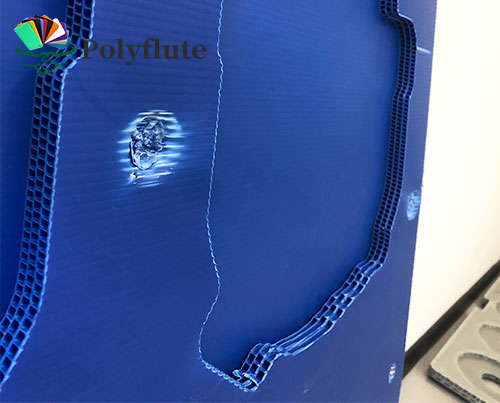

| Corrugated Plastic Pads | Lightweight with fluted structure for cushioning | Fragile goods, retail products |

| Textured Surface Pads | Pads with anti-slip textures to prevent movement | Food and beverage pallets |

| Perforated Plastic Pads | Pads with holes for airflow and moisture control | Fresh produce, pharmaceuticals |

Each type offers specific benefits depending on its construction and material strength. For example, solid plastic pads are ideal when weight support is critical, such as during the export of industrial goods. On the other hand, corrugated plastic pads are excellent for reducing shipping weight while still offering shock resistance.

Textured pads add surface friction, helping prevent cartons and boxes from sliding—especially useful in automated conveyor systems. Meanwhile, perforated pads ensure that temperature-sensitive or perishable items like fruits or vaccines remain ventilated during storage and transport, reducing spoilage risks.

When selecting the ideal pad type, always consider your product fragility, transport environment, and moisture exposure to ensure maximum protection and operational efficiency.

Plastic layer pads for pallets come in a variety of colors and sizes, not only to fulfill functional requirements but also to meet branding, sorting, and safety standards in logistics, warehousing, and manufacturing environments.

The most commonly used colors for plastic pallet layer pads include:

Color-coding using different plastic layer pad colors can simplify workflow, improve accuracy in order fulfillment, and minimize human errors during palletizing and shipping operations.

Plastic layer pads come in a range of standard sizes, typically designed to match the most commonly used pallet dimensions globally. Some popular standard sizes include:

| Standard Size (mm) | Standard Size (inches) | Fits Pallet Type |

|---|---|---|

| 1200 x 1000 mm | 47.2 x 39.4 in | ISO standard pallet |

| 1200 x 800 mm | 47.2 x 31.5 in | Euro pallet |

| 1140 x 1140 mm | 44.9 x 44.9 in | Australian standard pallet |

| 1100 x 1100 mm | 43.3 x 43.3 in | Asian pallet |

| 1219 x 1016 mm | 48 x 40 in | North American GMA pallet |

These sizes are chosen to sit flat on pallets without overhang, ensuring safe stacking and stability during transport. Custom sizes are also available upon request, particularly for industries with non-standard packaging needs, such as automotive components or high-end electronics.

In addition to base dimensions, plastic layer pads also vary in thickness, commonly ranging from 2 mm to 5 mm. Thicker pads are generally used for heavier items or when extra durability is required for multi-use purposes. Thinner pads are lighter, more cost-effective, and suitable for lightweight or disposable applications.

Beyond standard color and size offerings, many suppliers (including Polyflute) provide custom printing options such as logos, barcodes, QR codes, or warning labels directly onto the plastic surface. This adds value in terms of brand visibility, inventory tracking, and compliance labeling.

UV-resistant and anti-static variants are also available for sensitive environments like electronics manufacturing or outdoor storage, ensuring longevity and performance regardless of the usage condition.

The versatility of plastic layer pads for pallets makes them an essential solution across various industries, where protection, hygiene, and efficient stacking are critical for successful logistics. Their ability to separate and stabilize layers of goods on a pallet enhances safety during transportation and streamlines warehouse operations.

| Industry | Use Case Description |

|---|---|

| Food & Beverage | Used to separate and support cartons or bottles; helps maintain structural integrity and freshness by allowing airflow. |

| Pharmaceuticals | Offers hygienic barriers between layers of medication packages; moisture-resistant and easy to sterilize. |

| Electronics | Prevents shifting or impact damage to fragile devices; anti-static versions are available for sensitive components. |

| Manufacturing | Used for heavy-duty industrial parts to improve stackability and ease of loading/unloading. |

| Retail & Distribution | Keeps boxes aligned and clean during last-mile delivery; branding-friendly for clear identification. |

Let’s dive deeper into these applications:

By serving such a wide range of sectors, plastic layer pads for pallets not only optimize supply chain operations but also contribute to reduced waste, enhanced safety, and improved load performance during transport and storage.

Selecting the most suitable plastic layer pads for pallets is essential for ensuring load safety, maximizing efficiency, and reducing long-term operational costs. Here are some key factors to evaluate:

To maximize the lifespan of your plastic pallet layer pads, consider these maintenance tips:

Proper maintenance not only extends pad life but also ensures compliance with hygiene standards.

Here’s a quick comparison between plastic layer pads and other common materials:

| Material | Durability | Moisture Resistance | Cost | Reusability |

|---|---|---|---|---|

| Plastic Pads | High | Excellent | Moderate | High |

| Cardboard Pads | Moderate | Poor | Low | Low |

| Foam Pads | Low | Moderate | Moderate | Low |

Plastic layer pads clearly outperform in durability and moisture resistance, making them a preferred choice for demanding logistics operations.

Q: Can plastic layer pads be customized?

A: Yes, many manufacturers offer custom sizes, thicknesses, shapes, and colors to suit specific palletizing needs, branding requirements, or automated handling systems.

Q: Are plastic layer pads recyclable?

A: Most plastic pads are made from recyclable materials such as polypropylene (PP) or polyethylene (PE) and can be reprocessed at the end of their lifecycle, contributing to sustainable logistics.

Q: How do plastic layer pads improve pallet stability?

A: Their textured or corrugated surfaces increase friction between stacked layers, minimizing sliding, shifting, or tilting during transport or warehouse movement.

Q: Are plastic layer pads suitable for food-grade applications?

A: Yes, food-grade plastic layer pads are available. These are manufactured from virgin plastic resins that comply with FDA or equivalent food safety standards, ensuring hygiene in direct or indirect contact with food packaging.

Q: How long do plastic layer pads typically last?

A: With proper use and handling, plastic layer pads can be reused hundreds of times. Their lifespan depends on the type of plastic, usage conditions, and handling care, making them a cost-effective and durable alternative to cardboard or fiberboard layers.

Incorporating plastic layer pads for pallets into your logistics strategy enhances product protection, stability, and cost-efficiency. Their durability and versatility make them suitable for a wide range of industries and applications. Understanding the benefits and selecting the right type can significantly improve your supply chain performance.

If you’re looking for high-quality plastic layer pads for pallets or corrugated plastic sheets, trust Polyflute for durable, customizable solutions tailored to your business needs. Contact us today to learn more!