Corrugated plastic sheets have become a staple in numerous industries, prized for their versatility, durability, and cost-effectiveness. Among them, heavy duty corrugated plastic sheets are especially valued for their exceptional strength and robustness, enabling them to withstand demanding environments and heavy usage. This comprehensive guide will explore the meaning of heavy duty corrugated plastic sheets, their features, benefits, common applications, purchasing considerations, installation tips, and a detailed price comparison with thinner corrugated plastic sheets.

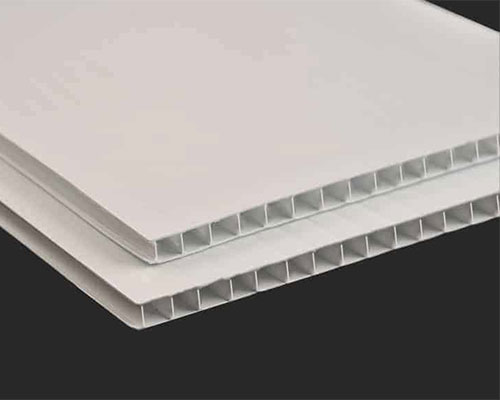

Heavy duty corrugated plastic sheets are specialized multi-layered plastic panels made primarily from high-density polypropylene (PP) or polyethylene (PE). They feature a fluted core sandwiched between two flat plastic layers, creating a structure that is lightweight yet remarkably strong. The “heavy duty” classification refers to sheets that are thicker, with reinforced ribs and more robust plastic composition, designed to endure higher mechanical stresses, resist impacts, and perform reliably in harsh environments.

Unlike their thinner counterparts used mainly for light-duty tasks like temporary signage or packaging, heavy duty corrugated plastic sheets are engineered for industrial, commercial, and heavy outdoor use.

Understanding the characteristics of heavy duty corrugated plastic sheets sheds light on why they are preferred for tough applications:

The reinforced fluted core and thicker walls enable these sheets to absorb shocks and resist cracks or breakage. This makes them ideal for construction sites, protective barriers, and industrial environments where impact is common.

Heavy duty sheets are often UV stabilized and resistant to rain, moisture, and temperature fluctuations. They maintain their structural integrity and appearance even after prolonged exposure to sunlight and outdoor elements.

Despite their strength, these sheets weigh significantly less than metal or wood alternatives. This reduces shipping costs and simplifies handling and installation.

Polypropylene and polyethylene plastics do not rust or degrade easily when exposed to chemicals, acids, or alkalis, making heavy duty sheets suitable for use in chemical plants, food processing facilities, and outdoor settings.

Most heavy duty corrugated plastic sheets are recyclable, supporting sustainability efforts and reducing environmental waste.

Manufacturers offer a wide range of thicknesses (usually from 4mm to 12mm or even thicker), customizable sheet sizes, and colors, accommodating diverse project requirements and aesthetic preferences.

The numerous advantages of heavy duty corrugated plastic sheets make them indispensable across various sectors:

These sheets far outlast cardboard, thin plastic, or plywood alternatives, translating to fewer replacements and lower maintenance expenses.

Heavy duty sheets can be easily cut, folded, glued, or welded. This adaptability allows for creative customizations, from packaging solutions to structural components.

While the upfront cost is higher than thin sheets or traditional materials, the longevity and minimal maintenance of heavy duty corrugated plastic sheets make them economical over time.

The sheets are impervious to water absorption, which prevents warping, rotting, or mold growth — a significant advantage in wet or humid environments.

Compared with glass or metal panels, heavy duty corrugated plastic sheets are shatterproof and safe to handle, reducing the risk of workplace injuries.

Heavy duty corrugated plastic sheets find utility in a broad range of industries due to their versatility, durability, and resistance to harsh conditions. Below are some of the most common applications across different sectors:

In construction, heavy duty corrugated plastic sheets serve as excellent temporary protection solutions. They are widely used for temporary wall and floor protection during renovations, safeguarding surfaces from damage caused by heavy foot traffic, tools, and materials. Their waterproof nature makes them ideal as concrete curing blankets and roofing underlayment, helping retain moisture during curing and preventing leaks. Additionally, these sheets are used as protective barriers around equipment or hazardous zones to ensure site safety and prevent unauthorized access.

Agriculture benefits significantly from the use of these sheets. They are employed as greenhouse panels that balance light transmission and insulation, promoting optimal growing conditions for plants. Heavy duty corrugated sheets also function as protective covers to shield crops from pests, wind, and extreme weather conditions, reducing crop damage and improving yield. Moreover, they are fashioned into durable shelters for livestock or farm equipment, providing long-lasting protection against the elements and wear.

The advertising industry uses heavyweight corrugated plastic sheets for outdoor, weatherproof signage and billboards that need to withstand sun, rain, and wind without fading or warping. Their smooth surfaces and ease of printing make them perfect for durable exhibition panels and point-of-sale displays that require a professional look and repeated use. Additionally, these sheets are frequently employed as long-lasting directional signs in public spaces, guiding visitors clearly in parks, campuses, or events.

In packaging, these sheets provide reusable and sturdy solutions. They are used to create reusable crates, boxes, and pallet liners that protect heavy or fragile goods during transport. Their rigidity and shock absorption make them ideal for separators and protective inserts in heavy-duty shipments, reducing product damage and improving stacking efficiency.

Heavy duty corrugated plastic sheets serve as liners for truck beds and cargo holds, protecting surfaces from scratches, dents, and corrosion. Within vehicles, they act as protective barriers and guards, ensuring the safety of both cargo and vehicle components from shifting loads and impact.

In industrial settings, these sheets are employed as machine guards and safety shields, protecting operators from moving parts and debris. Their chemical resistance makes them suitable for chemical-resistant walls or partitions, ensuring safety in processing plants. Additionally, they are used for temporary fencing or crowd control panels during events or construction projects, providing quick and sturdy barriers.

Selecting the most suitable heavyweight corrugated plastic sheets involves considering several key factors:

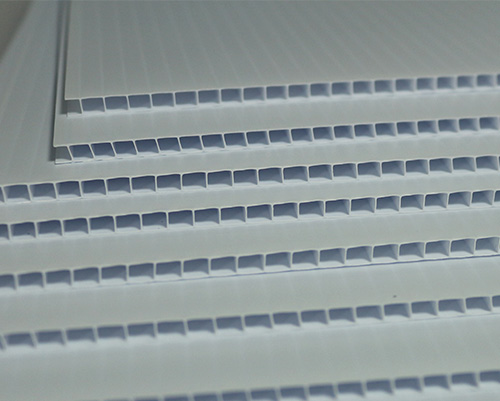

Typical heavy duty sheets range from 5mm to over 12mm in thickness. Thicker sheets provide greater rigidity and durability but come at a higher cost and slightly increased weight. The right thickness depends on the required strength, load, and environmental exposure of your project.

High-density polypropylene (HDPP) and high-density polyethylene (HDPE) are preferred for their mechanical strength and resistance to UV and chemicals. Verify that sheets are UV-stabilized for outdoor use.

Choose sheet dimensions that minimize cutting waste and fit your application without excess trimming.

Smooth sheets are ideal for printing and signage, whereas textured finishes may be better for anti-slip surfaces or aesthetic reasons.

Color choice can affect heat absorption, visibility, and aesthetics. For example, white reflects sunlight to reduce heat buildup, while darker colors absorb heat but may offer better dirt camouflage.

If your application requires fire safety compliance, check if the sheets meet relevant fire retardancy standards.

To maximize performance and lifespan, proper installation and care are essential:

Understanding the price differences between heavy duty and thin corrugated plastic sheets is crucial for budgeting and project planning.

| Feature | Heavy Duty Corrugated Plastic Sheets | Thin Corrugated Plastic Sheets (2-4mm) |

|---|---|---|

| Typical Thickness | 5mm to 12mm+ | 2mm to 4mm |

| Price Range (per sqm) | Higher (usually 30%-50% more) | Lower (budget-friendly) |

| Durability | Very High | Moderate |

| Impact Resistance | Excellent | Limited |

| Suitable Applications | Industrial, construction, outdoor, heavy-duty packaging | Temporary signage, indoor use, light packaging |

| Lifespan | Long-lasting | Short to medium-term |

| Cost-Effectiveness | Higher initial cost, lower maintenance cost | Lower upfront cost, may need frequent replacement |

Heavyweight corrugated plastic sheets command a higher price due to their thicker construction, more robust materials, and manufacturing complexity. They typically cost 30% to 50% more per square meter than thin sheets. However, this higher price brings substantial benefits:

On the other hand, thin corrugated plastic sheets (usually 2mm to 4mm thick) are suitable for lightweight, short-term projects. They are cost-effective for uses such as temporary indoor signage or packaging but lack the durability and strength for heavy-duty environments.

Choosing between heavy duty and thin sheets ultimately depends on your project’s specific requirements and budget constraints.

Heavy-duty corrugated plastic sheets offer a unique balance of properties compared with traditional materials like wood, metal, or standard plastics.

| Feature | Heavy Duty Corrugated Plastic | Wood | Metal | Standard Plastic |

|---|---|---|---|---|

| Weight | Lightweight | Heavy | Heavy | Lightweight |

| Moisture Resistance | Excellent | Poor (prone to rot) | Good (rust prone) | Fair |

| Durability | High | Moderate | Very High | Low to Moderate |

| Cost | Moderate | Low to Moderate | High | Low |

| Ease of Handling | Easy | Moderate | Difficult | Easy |

| Maintenance | Low | High | Medium | Medium |

Heavy duty corrugated plastic panels provide:

An important advantage of corrugated plastic sheets with heavyweight is their environmental profile. Made from recyclable plastics such as polypropylene and polyethylene, these sheets can be reprocessed into new products, reducing landfill waste.

Additionally, the longevity of heavy-duty sheets means fewer raw materials are consumed over time. Many manufacturers now offer take-back or recycling programs, further supporting a circular economy.

Heavy duty corrugated plastic panels are an excellent choice when strength, durability, and weather resistance are essential. Their robust construction makes them suitable for a wide range of demanding applications — from construction and agriculture to industrial and transportation uses.

While the upfront price is higher compared to thin corrugated plastic sheets, the long-term benefits in durability, reduced maintenance, and overall performance make heavy duty panels a smart investment for projects requiring reliability and toughness.

When selecting the right product, carefully consider thickness, material quality, size, surface finish, and environmental factors. Proper installation and maintenance will ensure your extra-thick corrugated plastic sheets deliver maximum value over their lifespan.

Whether you need protection for a construction site, reusable packaging, or sturdy outdoor signage, heavy duty corrugated plastic panels provide an unbeatable combination of performance and cost-effectiveness. Welcome to contact Polyflute for price of these heavy duty corrugated plastic sheets.