Corrugated plastic sheets are widely used across various industries and applications due to their lightweight, water-resistant, and impact-resistant nature. Whether you’re building a greenhouse, installing a shed roof, or working on signage, these sheets offer affordability and functionality. However, they’re not indestructible. Over time, due to environmental exposure, accidental impact, or improper installation, these plastic panels may develop cracks, punctures, or become detached. Knowing how to fix corrugated plastic sheets is essential for maintaining your projects and avoiding the cost and hassle of full replacement.

This guide will walk you through the process of identifying common problems, selecting the right tools and materials, and performing effective repairs—whether you’re dealing with small cracks or full-blown holes. By applying the correct repair techniques, you can significantly extend the life of your corrugated plastic sheets and maintain their performance and visual appeal.

Corrugated plastic sheets, though known for their durability, are still susceptible to damage over time. The type and extent of damage will determine the appropriate repair method. Common issues include the following categories:

Cracking

These cracks often occur due to age-related brittleness, UV radiation, or impact from debris like falling branches or hail. Even a small crack can expand over time, especially if moisture gets inside and freezes, causing the crack to widen.

Punctures or Holes

These can happen when a sharp object impacts the sheet. These holes can allow water to seep through, making them a critical issue for roofing and greenhouse applications.

Warping

Warping is a concern, particularly if the plastic is exposed to high temperatures or is stored improperly before installation. Warped sheets can lead to improper sealing and water leakage.

Loosening of Fasteners

Over time, fasteners may loosen due to thermal expansion or wind pressure. When this happens, sheets can become misaligned, rattle in the wind, or even get blown off entirely.

✅ Tips:Identifying these issues early is crucial because minor damage can often be fixed easily, while ignoring it may lead to larger structural problems or expensive replacements.

Before you start any repair work, gather all the tools and materials you’ll need for a smooth and effective process. Using the right tools not only ensures a durable repair but also reduces the chances of causing further damage during the process.

| Tool / Material | Description and Purpose |

|---|---|

| Utility Knife or Plastic Sheet Cutter | Essential for trimming damaged areas or cutting out patches from spare corrugated plastic. Ensures clean, accurate cuts for precise repairs. |

| Plastic Drill Bit | Useful when creating new holes or enlarging existing ones to fit new fasteners. Designed to prevent cracking or splitting of plastic during drilling. |

| Measuring Tape and Marker Pen | Crucial for accurately sizing your patches and marking drill points. Helps ensure all cuts and holes are placed exactly where needed. |

| Clean, Dry Cloth or Sponge | Needed to clean the surface before applying any adhesive or patch. A clean area improves bonding strength and ensures a lasting fix. |

| Clear Plastic Epoxy or Waterproof Adhesive | A critical bonding material for repairs. Choose high-quality adhesives that are compatible with the type of plastic you’re working with (e.g., polypropylene or polycarbonate). |

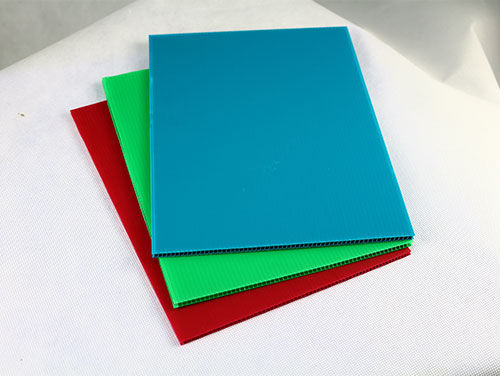

| Spare Corrugated Plastic Sheets | Ideal for patching. Use sheets made of the same material and color for seamless and effective repairs. Ensures visual consistency and material compatibility. |

| UV-Resistant Sealing Tape | Good for minor or temporary repairs. It resists sun damage and provides a decent seal for small cracks or punctures. |

| Screws with Rubber Washers | Needed to reattach sheets securely. Rubber washers help prevent leaks and protect the sheet from cracking under pressure. |

| Caulking Gun and Silicone Sealant | Used to complete the repair with watertight sealing. Fills in gaps and prevents future leaks, especially important for roofing and greenhouse applications. |

✅ Tip: Having everything at hand before you begin saves time and makes the repair process more efficient. Being well-prepared helps reduce mistakes and ensures a smoother overall experience.

Fixing cracks and holes in corrugated plastic sheets doesn’t have to be difficult, but it does require attention to detail and a methodical approach.

Start by thoroughly cleaning the damaged area. Use a sponge and mild soap solution to remove any dirt, moss, or oil. Dirt and debris can interfere with the adhesive bond and weaken your repair. Allow the surface to dry completely before proceeding.

For small cracks, a clear plastic epoxy or adhesive may be sufficient. Apply the epoxy directly into the crack using a syringe or fine applicator. Be sure to press the crack together firmly and hold it until the adhesive sets.

For larger cracks or holes, cut a patch from a matching corrugated plastic sheet. Make sure the patch extends 2 to 3 inches beyond the damaged area on all sides for adequate coverage.

Apply the adhesive generously around the crack or hole, then press the patch firmly into place. You can use clamps or heavy weights to hold it in position while it cures. If you want additional strength, drill holes through both the patch and the base sheet, and insert plastic-compatible screws with rubber washers. This prevents future leaks and adds mechanical security.

After securing the patch, use UV-resistant sealant or silicone around the edges to form a waterproof barrier. Let the repair sit undisturbed for 24 to 48 hours, depending on the adhesive’s curing time.

✅ Result: Once fully cured, the sheet should be watertight and structurally sound.

Loose or detached sheets are common, especially in roofing applications where wind, rain, and thermal expansion can dislodge them over time. If you notice a section of your sheet flapping in the wind or showing signs of separation, it’s time to take action before it causes leaks or further damage.

Begin by inspecting the fasteners. If nails or screws have rusted, pulled out, or broken, remove them carefully. Use a drill with a plastic drill bit to create new fastening holes slightly above or below the original ones. This allows you to secure the sheet more effectively without reusing weakened or oversized holes.

Always use corrosion-resistant screws—preferably stainless steel—with rubber washers. These washers create a watertight seal and cushion the plastic against cracking during tightening. When fastening, avoid overtightening as it can stress the plastic and cause new cracks or splits, especially in cold weather when the material is more brittle.

Align the sheet correctly with the adjacent panels before securing it. Make sure the corrugations line up and that water runoff won’t be obstructed. If there are existing seals between sheets, reapply silicone or appropriate plastic-compatible sealant to restore waterproofing. Once secured, give the sheet a gentle tug to confirm it’s fixed properly and won’t shift during wind or rain.

The best way to reduce the need for repairs is through regular maintenance. Corrugated plastic sheets require little upkeep, but even simple steps can drastically extend their lifespan.

Begin with regular cleaning—every three to six months is ideal. Use a soft brush or sponge with mild detergent to remove dust, bird droppings, and algae buildup. This prevents staining and allows you to inspect the surface for cracks or discoloration.

After heavy storms or wind events, inspect your structure for signs of movement, misalignment, or impact damage. Catching issues early allows for simpler and cheaper fixes.

If your sheets are exposed to strong sunlight, consider applying a UV protective coating to minimize degradation from UV rays. This is especially important for polycarbonate sheets, which can yellow or become brittle over time without protection.

It’s also wise to recheck all fasteners annually. Tighten any loose screws and replace damaged ones. Over time, temperature fluctuations cause expansion and contraction in both the plastic and its fasteners, which can lead to small gaps.

Resealing the joints and overlaps every couple of years with waterproof sealant will ensure the structure remains leak-free and well insulated.

If you have spare sheets from the original installation, store them flat and away from direct sunlight. They’ll be invaluable for future repairs or extensions.

Whenever you’re working with corrugated plastic sheets—especially when they’re installed on rooftops or elevated structures—safety should be your top priority. Start by choosing a calm, dry day for outdoor repairs to reduce the risk of slips or wind-related accidents. Always use a sturdy ladder with proper footing and, if working above ground, wear a harness or fall protection gear.

Wear safety goggles to protect your eyes from plastic shavings and adhesives. Gloves are recommended not only for hand protection but also for better grip when handling slippery surfaces or adhesive-laden materials. If you’re using power tools like drills or grinders, make sure they’re functioning properly and that you understand their operation.

When cutting plastic sheets, always do so on a stable, flat surface using a sharp utility knife or shears specifically designed for plastics. Rushing through repairs or using the wrong tools can cause further damage and injury. Also, keep your workspace clear of clutter to avoid tripping hazards, and make sure children and pets are kept away during the process.

Finally, follow the safety instructions of all repair materials. Some adhesives or sealants can emit strong fumes, so ensure adequate ventilation if you’re working in an enclosed space like a greenhouse or shed.

Although repairing corrugated plastic sheets is usually cost-effective, there are times when replacement is the smarter and more durable choice.

If the sheet has multiple large cracks, severe warping, or discoloration due to UV exposure, it may no longer perform its function adequately. Yellowed or brittle sheets often indicate material fatigue and can shatter or fail unexpectedly.

You should also consider replacement if more than 30% of the sheet is damaged. Excessive patching can compromise both structural integrity and water resistance, leading to long-term maintenance problems.

When holes extend across several corrugation channels, even high-quality patches may not restore full functionality. In these cases, removing the entire sheet and installing a new one ensures better waterproofing and mechanical stability.

If you’re planning a significant upgrade or aesthetic overhaul of your structure, replacing older sheets with new, UV-treated, or insulated versions may also improve durability and energy efficiency. Newer sheet materials often have better properties than older ones, making replacement a smart long-term investment.

Understanding how to fix corrugated plastic sheets is a valuable skill for anyone involved in DIY projects, home repairs, or greenhouse maintenance. From small cracks to large punctures, and from loose panels to aging fasteners, timely and correct repair methods can restore the sheet’s integrity and functionality with minimal cost.

By following the steps outlined in this guide—preparing your tools, assessing the damage, choosing the right repair strategy, and applying maintenance practices—you can maximize the lifespan of your corrugated plastic sheets. Remember, prevention is just as important as repair. Regular inspection, cleaning, and care are essential for avoiding future problems.

So whether you’re patching a roof, fixing a greenhouse panel, or re-securing a plastic wall, you now have the knowledge and techniques to do it right. Keep this guide handy and refer back to it whenever your corrugated plastic needs attention.

Of course, if you prefer to replace rather than repair, feel free to contact Polyflute – a professional manufacturer of PP corrugated plastic sheets. Reach out to us today for a product quote!

For more information, please click: https://polyflute.com/

WhatsApp: +86-150-62936841

Email: Sophia@polyflute.com