Introduction: Why PP Floor Protection Sheets Are Essential in Modern Construction

In the fast-paced world of construction and renovation, safeguarding floor surfaces during the project has become a top priority. Whether it’s a new residential build, a commercial remodel, or interior painting, floors are among the most vulnerable surfaces. Enter PP floor protection sheets—an innovative, durable, and cost-effective solution designed to keep floors safe from damage, dust, paint spills, and debris.

In this comprehensive guide, we’ll dive deep into everything you need to know about PP floor protection sheets: their types, key benefits, practical applications, and what to consider when choosing the best product for your needs.

PP floor protection sheets are temporary protective coverings made from polypropylene (PP)—a thermoplastic polymer known for its excellent chemical resistance, toughness, and flexibility. These sheets are widely used in the construction industry due to their superior durability and lightweight properties.

Key features include:

| Feature | PP Floor Protection Sheets | Cardboard Sheets | Fabric Rolls | Plastic Films |

|---|---|---|---|---|

| Water Resistance | Excellent | Poor | Moderate | High |

| Durability | High | Low | Low | Moderate |

| Reusability | Yes | No | Yes | No |

| Cost-effectiveness | High (over multiple uses) | Low | Moderate | Low |

PP floor protection sheets outperform many alternatives when it comes to long-term value and protection under heavy foot traffic.

Understanding the different types of PP floor protection sheets is crucial when selecting the right product for your specific project needs. Each type serves a unique purpose and is designed to suit different floor types, working conditions, and levels of wear-and-tear.

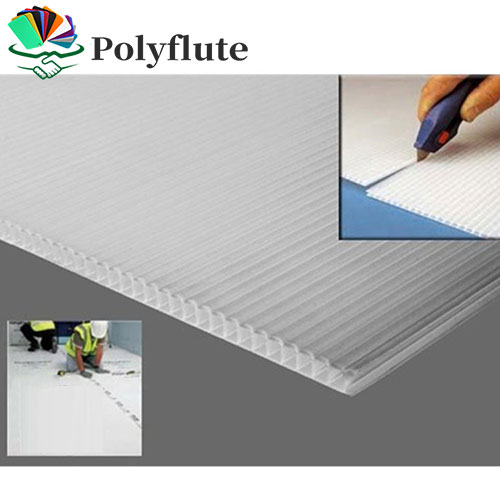

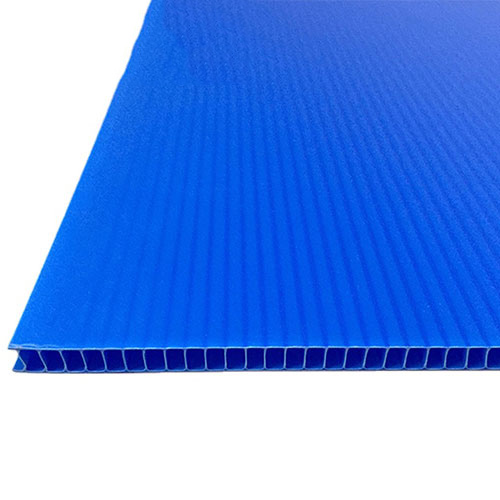

Corrugated polypropylene sheets are twin-wall, fluted plastic boards made through an extrusion process. The inner fluting provides structural integrity without significantly increasing weight, making these sheets easy to handle yet remarkably durable.

Key Features:

Common Sizes: 1.2m x 2.4m (can be cut or customized on-site)

Thickness Range: 2mm to 5mm

Colors: Black, White, Grey, Blue (custom options available)

Surface Texture: Anti-slip, smooth or lightly textured

Ideal Applications:

Due to their rigidity and load resistance, corrugated PP sheets are particularly favored in commercial and industrial flooring protection projects. Their air-layered core provides extra cushioning against tools or machinery impacts, reducing the risk of damaging underlying floors.

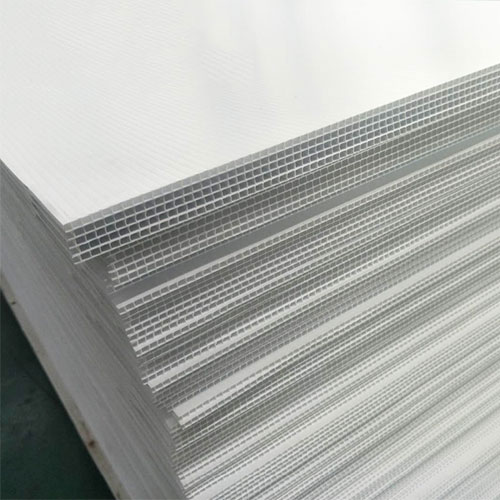

Flat PP sheets are designed for simpler, cleaner applications. Unlike their corrugated counterparts, these sheets are solid and uniform in thickness, offering smooth surface coverage without raised ridges or air gaps.

Key Features:

Thickness Options: 2mm–3mm

Surface Finish: Matte for reduced glare or gloss for better visibility

Color Options: White, light grey, beige (or custom)

Best Used For:

These sheets offer a non-intrusive appearance and are ideal for work that demands cleanliness and aesthetics, such as during hotel renovations or showroom setups.

Honeycomb PP sheets represent the premium category of PP floor protection sheets. Their internal honeycomb structure gives them superior load-bearing capacity and impact resistance, without adding significant weight.

Benefits:

Recommended For:

Customization Options:

Honeycomb sheets are more expensive, but their longevity, strength, and elegant appearance make them the preferred choice for projects where flooring is a significant investment.

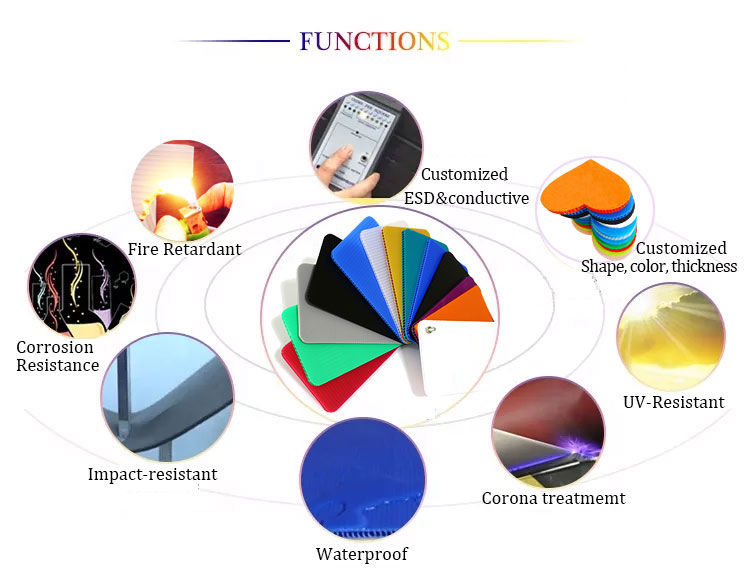

All PP floor protection sheets are made from high-quality polypropylene (PP), known for its durability, chemical resistance, and lightweight properties. Standard color options include white, blue, grey, and black, each serving a practical or aesthetic function on-site. For example, white sheets are often used in clean environments to show dust or spills clearly, while black offers a more discreet and heavy-duty appearance. Additionally, custom colors can be produced based on branding needs or to align with site safety color codes, providing both functional and visual benefits.

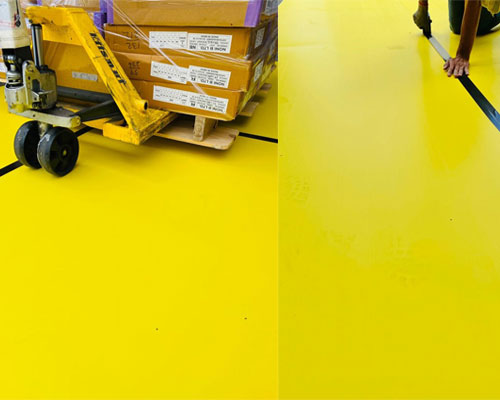

PP sheets can endure the heavy foot traffic of workers, wheeled trolleys, and falling tools without tearing or cracking. This makes them ideal for long-term use on construction sites.

Unlike paper-based protection materials, PP floor protection sheets resist water, oils, solvents, and chemicals. This feature prevents stains and corrosion on sensitive flooring.

Despite their strength, PP sheets are incredibly light. Workers can easily move and install them without special tools or training.

Most PP sheets are reusable for multiple projects. Since they can also be made from recycled polypropylene, they help reduce plastic waste and promote sustainability in the construction industry.

For projects with strict fire safety codes, flame-retardant PP sheets can be used.

While initial costs may be higher than paper or cardboard, PP floor protection sheets last much longer and require fewer replacements, reducing overall project costs.

PP floor protection sheets are a common sight in home building sites to protect hardwood, tile, or vinyl floors from paint, dirt, and scratches.

During office or factory renovations, these sheets help keep expensive flooring intact and reduce cleaning costs post-construction.

Used under stages, exhibition booths, or high-traffic zones in event halls.

PP sheets can also be used as floor mats in logistics centers to protect floor integrity under moving equipment or temporary installations.

For cleanroom or sterile applications, PP sheets offer a hygienic, easily sanitized surface.

Selecting the correct type of PP floor protection sheet depends on a combination of factors including project scale, floor type, reuse potential, and sustainability goals. Making the right choice ensures both effective protection and cost efficiency.

If you manage multiple ongoing projects, opt for high-durability PP sheets designed for reuse. While these might cost more initially, they offer significant savings per use over time and reduce waste. Always factor in not just the upfront price, but the lifecycle value.

Many commercial construction or public sector tenders now demand green building compliance, such as LEED, BREEAM, or local eco-building standards. Ensure your supplier can provide documentation and test reports for PP floor protection sheets made from recycled or recyclable polypropylene, free from hazardous additives.

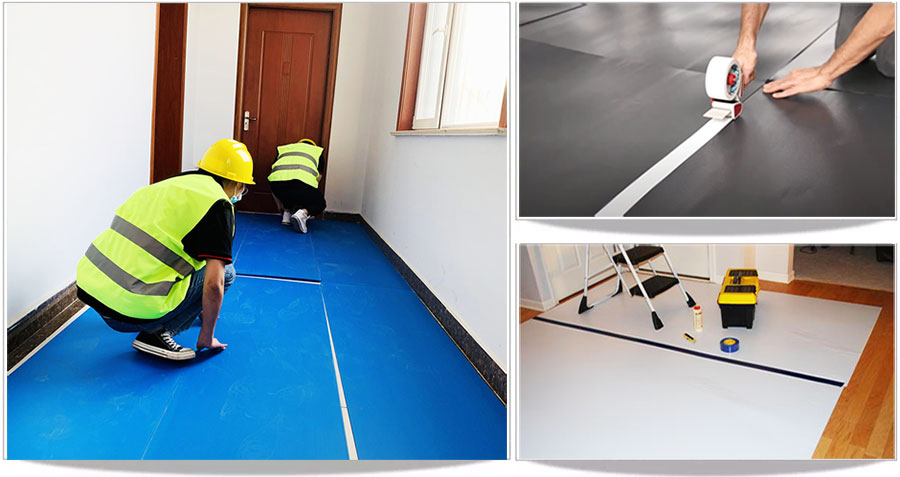

Proper installation ensures that PP floor protection sheets function effectively and safely throughout the project lifecycle. Follow these best practices for optimal results.

PP sheets can be easily cut with a sharp utility knife. For straight, clean cuts, always use a metal straight edge or T-ruler. For large-scale projects, pre-ordering custom-cut sizes can save on labor and material waste during installation.

To prevent sheet movement during work:

Choosing the right supplier is just as important as selecting the right product. Here’s how to ensure you’re getting top-quality PP floor protection sheets for your project.

Several countries stand out for manufacturing and exporting quality PP floor protection sheets:

You can source PP sheets through trusted B2B platforms like Alibaba, Made-in-China, or Global Sources. These platforms allow you to filter suppliers by certification, MOQ, and lead time. For long-term supply or OEM partnerships, consider contacting factories directly. Always verify supplier credentials, request product certifications, and obtain Material Safety Data Sheets (MSDS) or relevant test reports to ensure safety and compliance with your project requirements.

Polypropylene (PP) is a recyclable thermoplastic, making PP floor protection sheets a more sustainable choice compared to traditional single-use materials like paperboard or foam.

After usage:

Some companies even offer buy-back or take-back programs to collect used PP sheets, ensuring proper post-consumer waste management and reducing landfill pressure.

PP floor protection sheets are no longer a luxury—they’re a necessity for any responsible, cost-effective, and efficient construction or renovation project. Their versatility, strength, and reusability make them an ideal solution for a wide range of floor protection needs.

By investing in quality PP sheets and following best practices, you can reduce damage, cut cleanup time, and deliver better results for your clients. Whether you’re a contractor, builder, interior designer, or supplier, PP floor protection sheets are the future of surface safety.

Looking to buy PP floor protection sheets in bulk or want to learn more about customization options? Contact us today for free samples, factory pricing, and professional consultation for your next project.