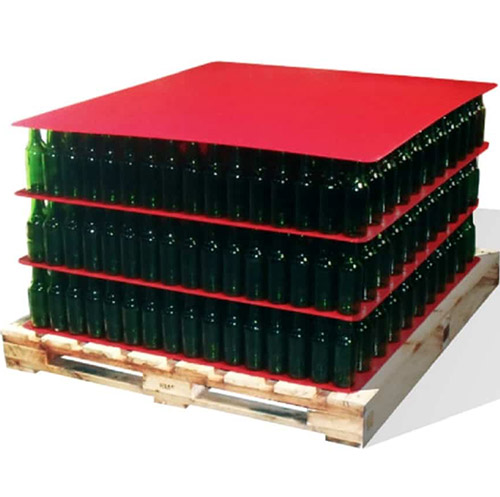

In industries such as beverage bottling, logistics, pharmaceuticals, and electronics, optimizing space and ensuring product safety during transport are top priorities. Among the many tools used to achieve this, plastic layer pads for pallets have emerged as a highly effective and increasingly preferred solution. Designed to offer superior durability, cleanliness, and reusability, these specialized sheets play a critical role in safeguarding goods between pallet layers.

This article delves into what plastic layer pads for pallets are, why they outperform traditional materials, and how they can be customized to meet the unique needs of your business.

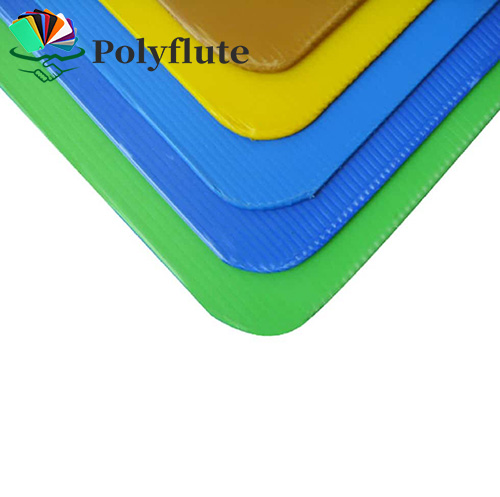

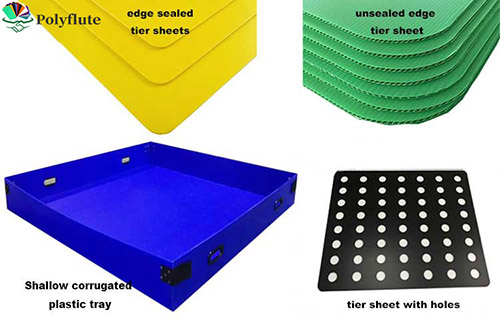

Plastic layer pads for pallets, also commonly referred to as pallet layer pads or plastic pallet layer pads, are flat sheets made from durable polypropylene (PP) materials, typically in a hollow, fluted structure known as corflute or PP corrugated plastic. These pads are designed to be placed between layers of products stacked on a pallet, serving both as a separator and a protector.

Unlike cardboard or paper-based alternatives, plastic layer pads are moisture-resistant, easy to clean, and capable of withstanding repeated use. They effectively prevent product shifting, reduce the risk of breakage, and provide a protective barrier against dust, dirt, and liquid contamination.

With growing awareness around hygiene and operational efficiency, the demand for plastic layer pads for pallets has expanded across numerous industries globally.

Traditionally, businesses have relied on cardboard and fiberboard for interlayer separation. While these materials are cost-effective in the short term, they have major limitations, particularly in environments with high humidity or where hygiene is crucial.

By replacing cardboard with plastic layer pads for pallets, businesses benefit from increased efficiency, reduced product damage, and better hygiene control—all while lowering waste management costs.

At Polyflute, we specialize in manufacturing high-performance plastic tier sheets engineered for diverse logistics and manufacturing applications. Our plastic layer pads for pallets stand out for their quality, customization options, and technical precision.

Key Features Include:

Special Properties:

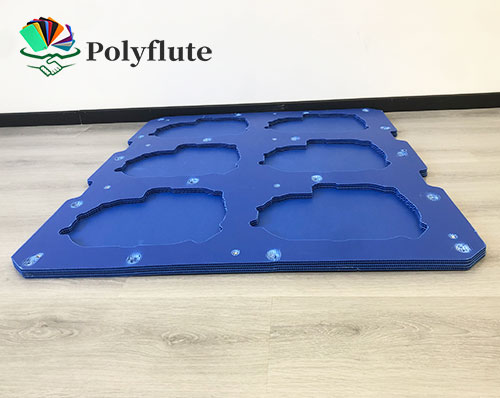

These options make plastic pallet layer pads suitable for high-value electronics, bottled beverages, automotive parts, and more. They ensure compliance with industry standards and cater to specialized logistics needs.

Additionally, Polyflute offers full OEM/ODM services to support your private labeling, custom printing, or project-specific requirements. Our commitment to quality and innovation helps customers achieve safer transport, reduced damage rates, and improved supply chain efficiency.

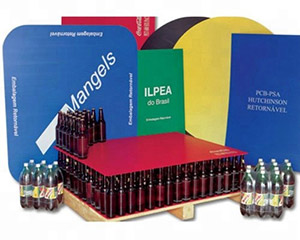

Plastic layer pads for pallets have found widespread usage in sectors where safety, hygiene, and logistical efficiency are vital. Below are some of the most common industries benefiting from these innovative interlayer solutions:

Beverage and Bottling

Breweries, mineral water plants, and juice manufacturers use our plastic pads to separate glass bottles and aluminum cans on pallets. Edge-sealed pads help prevent breakage from friction and reduce dust contamination. In this industry, thicker pads (3mm–5mm) with waterproof and chemical-resistant properties are popular to withstand moisture and liquid spills.

Food and Daily Goods

From canned food to hygiene products, manufacturers prefer plastic over cardboard for cleaner handling and better performance in refrigeration or cold chain conditions. Lightweight yet durable 2mm to 3mm pads with FDA-approved materials or food-grade certifications are commonly used to ensure hygiene compliance.

Electronics

Anti-static and conductive variants are widely used in electronics to avoid electrostatic damage during storage and shipping. Here, specialized ESD-protected plastic tier sheets with corona-treated surfaces enable safe stacking and printing of batch codes or handling instructions.

Pharmaceuticals

Plastic pads meet the industry’s rigorous standards for hygiene and contamination control. High-precision, sterilizable layer pads with smooth surfaces and fire-retardant properties are preferred to safeguard sensitive medicinal products.

Logistics & Warehousing

Whether in short-haul distribution or long-term storage, these pads protect goods, maintain stack integrity, and support automation in handling. Corrugated pads with reinforced edges and customizable sizes are commonly used to adapt to various pallet configurations and load weights.

The growing use of plastic layer pads for pallets in such diverse applications confirms their unmatched versatility and value. Their customizable thickness, size, and special properties ensure tailored solutions that improve safety, reduce product damage, and optimize supply chain efficiency across industries.

Polyflute offers a wide range of customization options for businesses that need tailored solutions for specific products and shipping conditions.

| Parameter | Specification |

|---|---|

| Size | Standard: 1200x1000mm, 1100x1000mm, 1250x1000mm |

| Custom Width: up to 2600mm | |

| Thickness | 2mm – 5mm |

| Color | Black, White, Blue, Grey, or Custom Colors |

| Material | Corrugated PP (Polypropylene) |

| Edge-Sealing | Available |

| Optional Features | ESD, UV-resistant, Fire-retardant, Printable Surface |

| Packing | Shrink film wrap or palletized according to request |

| MOQ | 1000 pieces |

| Sample | Free sample available upon request |

Our plastic layer pads for pallets can be precisely designed to align with the handling systems in your plant or warehouse. For example, selecting a certain pad thickness and surface treatment can increase stack stability when using automated palletizers or robotic arms.

Moreover, customized colors and printable surfaces improve product traceability and visual management in complex supply chains. Edge-sealing technology not only protects against moisture but also enhances the durability of pads in harsh environments, reducing replacement frequency and overall costs.

When considering plastic layer pads for pallets, pricing is a key factor for businesses aiming to balance quality and budget. The cost of these pads varies depending on factors such as size, thickness, material grade, and customization options like anti-static or UV resistance.

Below is a general price range for common specifications about the plastic layer pads, providing an overview for bulk purchasing decisions:

| Specification | Thickness | Approximate Price per Piece (USD) |

|---|---|---|

| Standard Size (1200x1000mm) | 2mm | $1.20 – $1.50 |

| Standard Size (1200x1000mm) | 3mm | $1.50 – $2.00 |

| Customized Size (<2600mm width) | 2mm – 5mm | $1.80 – $3.50 |

| Special Options (Anti-static, UV-resistant, etc.) | 3mm – 5mm | $2.50 – $4.00 |

Investing in high-quality plastic pallet layer pads is cost-effective in the long run due to their durability and reusability. Unlike disposable cardboard sheets, plastic pads reduce replacement frequency and lower waste disposal costs. Their resistance to moisture and damage ensures products remain protected during transit, minimizing losses from damaged goods.

Furthermore, many suppliers, like Polyflute, offer OEM/ODM services and bulk discounts, allowing businesses to customize and optimize costs based on specific operational needs. Considering these factors, plastic layer pads represent an economical and sustainable packaging solution.

The demand for plastic layer pads for pallets varies significantly across different countries and regions, influenced by industry requirements, regulations, and logistics conditions:

Understanding these regional needs allows Polyflute to offer tailored plastic layer pads for pallets that meet specific market demands, ensuring optimal performance and customer satisfaction globally.

Selecting the right pallet layer pad is crucial to achieving the highest return on investment and maintaining product integrity. Consider the following when choosing:

Product Weight & Fragility

Heavier or fragile goods require thicker pads or impact-resistant edges to prevent damage during stacking and transit.

Environmental Conditions

For high-moisture environments, use sealed and waterproof variants. Cold storage facilities might require fire-rated or UV-resistant versions to withstand extreme temperatures and exposure.

Material Sensitivity

For electronics or sensitive goods, opt for ESD-safe or conductive plastic materials to protect against static discharge.

Reusability Goals

If you require a long lifecycle, reinforced plastic pads are recommended. They provide cost-efficiency through repeated use (often 30–50 times), reducing waste and replacement costs.

Custom Branding or Sorting

Custom color-coding or printed logos can help streamline warehouse operations and enhance brand visibility, improving inventory management and product identification.

Additionally, consider your supply chain logistics, handling equipment compatibility, and sustainability goals when selecting the right pad. Polyflute’s experts are ready to guide you through selecting or designing the most suitable plastic layer pads for pallets, ensuring they fit your unique production, storage, and delivery workflow seamlessly.

The need for reliable, hygienic, and durable interlayer solutions has never been greater. Plastic layer pads for pallets are not just an upgrade—they are a strategic investment in efficiency, safety, and sustainability.

Compared to cardboard alternatives, they offer significant long-term savings and operational advantages across industries. Whether you’re handling delicate glass bottles, sensitive electronics, or everyday consumer goods, Polyflute provides customizable, high-performance plastic pallet layer pads that meet your specific needs.

📞 Contact Polyflute Today:

Let us help you design the ideal pallet layer pad solution to enhance your supply chain today!