In today’s fast-paced world of logistics, retail, and global trade, the demand for innovative packaging solutions is greater than ever. Among the emerging stars of this industry are custom coroplast boxes—a modern answer to the challenges of durability, sustainability, and customizability. These lightweight yet robust containers are taking the packaging world by storm, especially in applications where traditional cardboard or wood fails to deliver.

From protecting sensitive electronics during shipment to enhancing the visual appeal of retail displays, custom coroplast boxes offer versatility that few materials can match. This article explores their applications, design options, global standards, and why your business should consider switching to this advanced packaging solution.

Coroplast, often referred to as corrugated plastic or polypropylene (PP) twin-wall plastic, is a lightweight and durable material made from high-impact polypropylene copolymer. Structurally similar to corrugated cardboard but made from plastic, Coroplast features fluted channels sandwiched between two flat plastic sheets, offering excellent rigidity and strength without adding weight.

Custom coroplast boxes are packaging containers fabricated from this material, with tailored dimensions, thicknesses, colors, and printing options to suit various industrial and commercial needs. These boxes are waterproof, chemical-resistant, and highly reusable, making them ideal for environments where moisture, abrasion, or frequent handling would quickly wear out cardboard or other materials.

Compared to traditional packaging solutions, custom coroplast boxes provide enhanced performance in demanding conditions while also supporting branding efforts through high-quality UV printing.

One of the main strengths of custom coroplast boxes is their adaptability across industries. Whether used in food packaging or industrial transport, their protective characteristics and customizable design options make them a preferred choice worldwide.

Brands like Mister Potato use customized coroplast boxes to pack and ship snack products. The moisture-proof and grease-resistant properties of the material ensure hygiene and product integrity, while UV-printed branding helps boost shelf appeal.

Anti-static (ESD) variants of coroplast boxes are crucial for handling delicate electronics. These boxes reduce the risk of static discharge, offering a safe packaging solution for circuit boards, sensors, and other sensitive devices.

Hygienic, washable, and easy to sterilize, coroplast packaging is ideal for medical devices and pharmaceuticals. Custom inserts or dividers can be added to secure vials, bottles, or instruments during transit.

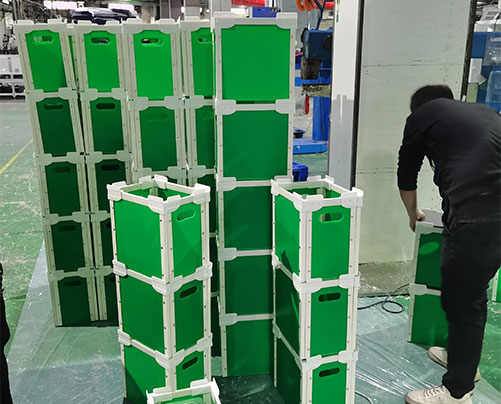

Durability is critical in supply chain operations. Custom coroplast boxes provide high impact resistance and load-bearing capacity, making them suitable for repeated shipping cycles and warehouse storage.

Thanks to UV printing capabilities, businesses use these boxes in promotional setups, point-of-purchase (POP) displays, and exhibition booths. They offer visual appeal while remaining easy to clean and assemble.

Custom coroplast storage boxes are ideal for organizing files, toys, clothing, and more. Their moisture-resistant surface prevents mildew and corrosion, making them useful in garages, basements, and humid climates.

The true strength of custom coroplast boxes lies in their remarkable design flexibility. These boxes are not simply containers—they are fully customizable packaging solutions that can be tailored to meet a wide range of branding, operational, and protective requirements. From exact sizing to specialized coatings and functional enhancements, every aspect of the box can be designed with precision.

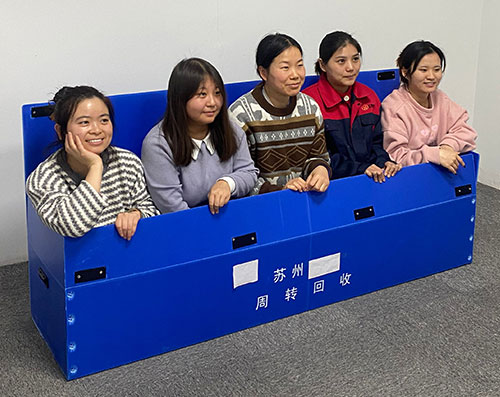

One of the most significant advantages of coroplast boxes is the ability to produce them in virtually any size. Whether you require compact bins for organizing small components or oversized crates for bulkier goods, dimensions can be customized to your exact specifications. This ensures maximum space efficiency during transport and storage, while also reducing material waste.

Standard thickness options typically range from 3mm to 5mm, but manufacturers can offer other gauges based on specific use cases. For example:

Thicker sheets not only enhance the box’s rigidity but also improve its shock absorption during handling and transportation.

Coroplast sheets come in a wide range of vibrant colors, including:

Choosing specific colors can serve multiple purposes. In warehousing, different colored boxes help with visual inventory sorting. In retail, bright colors and branded tones make your packaging instantly recognizable, reinforcing brand identity and market presence. For sensitive or critical applications (e.g., pharmaceuticals or electronics), color coding can help differentiate between product categories or departments.

With UV flatbed printing technology, manufacturers can print directly onto the surface of coroplast sheets. This allows for:

UV inks are weather-resistant, fade-proof, and ideal for both indoor and outdoor use. This feature is particularly valuable for businesses that require long-lasting signage, branded displays, or transport boxes exposed to sunlight and moisture.

Additionally, digital and screen printing methods are available depending on the print quantity, budget, and required visual impact.

Customization extends beyond size and aesthetics. Manufacturers can tailor the box’s sealing and assembly mechanisms to suit specific handling or reuse requirements:

Some custom coroplast boxes are engineered to be collapsible or foldable, reducing their volume during return shipping or storage, which enhances cost-efficiency in closed-loop supply chains.

To further adapt the boxes to specialized environments, manufacturers offer a variety of add-ons and enhancements, such as:

Moreover, depending on the intended application, the following material performance options are available:

These enhanced materials provide additional protection and compliance with safety standards across industries such as automotive, aerospace, food, pharma, and agriculture.

In addition to their physical versatility, custom coroplast boxes are eco-friendly and cost-efficient. Made from polypropylene (PP), they are 100% recyclable and contribute to reducing packaging waste through multiple-use cycles. Their lightweight construction lowers shipping costs, while their toughness reduces the need for frequent replacements.

Finally, packaging can be completed according to your requirements, including film wrapping, stretch-wrapping, or custom labeling, ensuring safe delivery and convenient unpacking.

While the core material remains consistent, different markets have specific preferences, certifications, and regulatory standards that manufacturers must consider.

China is one of the leading producers of coroplast packaging, offering cost-effective manufacturing and quick turnaround times. Factories here typically meet ISO 9001 quality standards and often provide OEM/ODM services for export clients.

European clients often demand compliance with REACH and RoHS standards, particularly for applications involving electronics or food-grade packaging. Eco-certification and recyclability are also emphasized due to the EU’s Green Deal policy.

In the United States and Canada, FDA approval is vital when boxes are used for direct food contact. North American customers also favor reusable options that can withstand the rigorous handling common in regional logistics.

In these regions, resistance to UV radiation and moisture is critical due to the climate. Corflute (as it’s often called locally) must be tailored to endure long-term outdoor exposure, especially for agricultural and building industry use.

By understanding the standards across different geographies, manufacturers can better cater to international markets and provide certification upon request.

Despite the higher upfront cost compared to single-use cardboard or foam packaging, custom coroplast boxes offer significant long-term savings and advantages:

Coroplast is impact-resistant, weather-proof, and less prone to tearing. A single box can be reused dozens or even hundreds of times without degrading.

These boxes are 100% recyclable. Because they are reusable, they also drastically reduce the waste generated by disposable packaging systems.

Unlike cardboard, coroplast does not absorb water or react with mild chemicals. This makes it ideal for humid, oily, or dusty environments.

With UV printing, businesses can reinforce their brand identity and stand out in crowded markets.

Though initial unit costs may be higher, the durability and reusability translate to lower total cost of ownership—especially in closed-loop logistics systems.

The term “Coroplast” is trademarked in North America, but similar materials go by different names across regions:

| Term | Region | Description |

|---|---|---|

| Coroplast | USA, Canada | Trademarked brand for corrugated polypropylene |

| Corflute | Australia, NZ | Generic term for corrugated plastic |

| Correx | UK, Europe | Often used in construction and signage |

| PP Hollow Sheet | Global | Generic industrial term, especially in Asia |

All of these refer to the same base structure: twin-wall polypropylene sheets. Depending on regional terminology, they are manufactured to different size conventions (mm vs inches) and may offer slight variations in additives or coatings.

Types of boxes include:

Understanding the distinctions helps international buyers source the correct specifications and align with local terminology during procurement.

Sustainability is no longer optional—it’s a necessity. With governments and consumers alike demanding greener business practices, custom coroplast boxes play a vital role in minimizing ecological impact.

These boxes are built for reuse. One durable coroplast box can replace dozens of single-use cardboard boxes over its lifespan.

Coroplast is made of polypropylene (PP), which is fully recyclable. At the end of its lifecycle, it can be reprocessed into new products with minimal energy input.

In logistics systems where packaging returns to the sender (closed-loop), using custom coroplast boxes reduces both waste and procurement costs. Businesses also save on storage, as foldable options require minimal space when not in use.

With certifications and eco-labels, manufacturers can demonstrate alignment with ESG (Environmental, Social, and Governance) commitments, making them more attractive to eco-conscious consumers.

Ordering custom coroplast boxes involves more than choosing size and color. It’s about collaborating with the right supplier who understands your industry’s unique needs.

China has become a hub for high-quality, cost-effective custom coroplast box manufacturing. With advanced machinery, skilled labor, and established export systems, Chinese suppliers can deliver on complex orders quickly.

When selecting a factory:

In the quest for efficient, eco-friendly, and visually appealing packaging, custom coroplast boxes stand out as a superior choice. Whether you’re managing a warehouse, promoting a consumer brand, or transporting delicate equipment, these boxes offer the reliability and flexibility your operation demands.

Their ability to adapt to various industries, withstand harsh environments, and reflect your brand identity—all while being reusable and recyclable—makes them a smart long-term investment.

If your business is looking to optimize logistics, enhance branding, and embrace sustainable practices, it’s time to consider switching to custom coroplast boxes. Contact Polyflute, Coroplast boxes with more than 15 years of experience.