Corflute boxes have become an essential packaging solution across various industries in Australia. Known for their lightweight, durable, and water-resistant properties, corflute boxes are widely used for transporting goods, displaying products, and even advertising. As the demand for efficient and eco-friendly packaging grows in the Australian market, corflute boxes stand out as a top choice.

Polyflute, a leading manufacturer of corflute boxes, supplies high-quality products suitable for export to Australia, meeting the diverse needs of Australian businesses. In this comprehensive guide, we will explore the different types of corflute boxes popular in Australia, how to choose the right ones for your business, and the pricing advantages of sourcing corflute boxes from China versus purchasing locally within Australia.

Corflute is a brand name often used interchangeably with corrugated plastic sheets. These sheets are made from polypropylene, making them lightweight yet tough, water-resistant, and reusable. Corflute boxes, crafted from these sheets, offer a versatile packaging solution ideal for protecting goods in transit or storage while also being easy to handle and environmentally friendly.

Australia’s diverse industries, from agriculture to logistics and retail, rely heavily on packaging that withstands the country’s sometimes harsh weather conditions. Corflute boxes are favored because:

Typical applications include packaging fresh produce, shipping industrial parts, housing construction materials, and point-of-sale displays.

Understanding the types of corflute boxes commonly used in Australia can help businesses make informed choices. Below we discuss the main variations based on color, size, and design.

While corflute sheets come in many colors, some are more prevalent in the Australian market due to practical and aesthetic reasons:

White: This is by far the most popular choice among Australian businesses. White corflute boxes provide a clean, professional appearance that suits a wide variety of industries, including retail, agriculture, and manufacturing. One major advantage of white corflute is its excellent printability — logos, product information, and branding can be easily and vividly printed, making it ideal for promotional packaging or product identification. Additionally, white reflects sunlight better than darker colors, helping to reduce heat absorption, which is particularly useful for products sensitive to temperature fluctuations during transport.

Black: Black corflute boxes are especially favored for outdoor and industrial applications in Australia. The black color offers superior UV resistance compared to lighter colors, making these boxes more durable under intense sunlight exposure, which is common in many Australian regions. Besides functional benefits, black corflute also conveys a sleek, professional look often preferred in high-end product packaging or when aesthetic appeal is crucial, such as electronics or automotive parts.

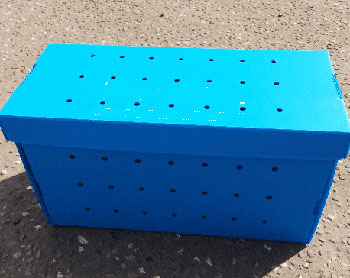

Blue and Other Colors: While less common than white or black, blue and other colored corflute boxes serve important roles in sectors that use color-coding for quick identification and inventory management. For example, blue corflute boxes might be assigned to a specific product line or warehouse zone, improving operational efficiency. Other vibrant colors like red, green, or yellow are also used in niche markets to meet branding or organizational needs.

Transparent/Clear: Transparent or clear corflute boxes are relatively rare but have specific applications, particularly in retail display environments. Clear corflute allows consumers to see the product inside without opening the box, which is ideal for promotional displays, samples, or delicate goods that benefit from visibility without compromising protection.

The choice of color in corflute boxes can impact not only the visual appeal but also practical considerations such as UV protection, heat retention, and brand communication. Australian businesses often balance these factors based on their specific product requirements and market expectations.

Australian businesses order corflute boxes in a wide range of sizes and thicknesses to suit diverse applications, from small packaging for retail products to large industrial crates.

Standard Sizes: Many corflute suppliers in Australia offer stock boxes in common sizes such as 600x400mm or 800x600mm. These sizes are ideal for general-purpose shipping and storage and fit well within standard pallet dimensions, making logistics simpler and more cost-effective. Standard sizes also allow businesses to maintain inventory efficiently without the complexity of managing multiple custom dimensions.

Custom Sizes: For many industries, off-the-shelf box sizes don’t meet specific needs. Manufacturing companies, agricultural producers, and logistics firms often require tailor-made corflute boxes to accommodate irregularly shaped products, fragile items, or specialized machinery parts. Custom sizing not only protects goods better but can also optimize space usage in transport vehicles or warehouses, reducing costs.

Thickness Choice: Thickness of corflute sheets used in boxes generally ranges from 3mm up to 10mm. Thinner corflute (3-4mm) is typically chosen for lightweight or less fragile goods, offering a balance between protection and economy. Thicker sheets (6-10mm) provide superior durability and impact resistance, essential for heavier items or those subjected to rough handling during transit. In Australia’s variable climate and often rugged transport conditions, choosing the right thickness ensures product safety and reduces damage-related losses.

Corflute boxes come in a variety of structural formats, each suited to different logistical and storage needs in the Australian market:

Foldable/Collapsible Boxes: These are highly popular among Australian companies seeking space-efficient packaging solutions. Foldable corflute boxes can be easily collapsed when not in use, saving valuable warehouse space and reducing return freight costs. Their reusable nature makes them an economical and environmentally friendly option, particularly in supply chains with high turnover and return logistics.

Rigid Boxes: Rigid corflute boxes are designed for maximum protection, ideal for sensitive or heavy items such as electronics, automotive components, or glass products. The robust construction minimizes the risk of crushing or impact damage, making them suitable for export shipments where handling conditions can be unpredictable.

Boxes with Handles or Inserts: To improve ergonomics and product security, many corflute boxes are customized with handles, partitions, or foam inserts. Handles facilitate easier manual handling and transport, reducing workplace injury risks. Inserts protect fragile items from shifting inside the box, which is especially important for delicate electronics or precision instruments.

Reinforced Edges and Corners: Reinforcement enhances the structural integrity of corflute boxes, making them more resistant to wear and tear during transit, stacking, and storage. This feature is particularly valued by Australian exporters whose goods often endure long shipping routes and multiple transfers.

The versatility of corflute box designs allows Australian businesses to tailor their packaging to specific operational needs, balancing protection, convenience, and cost. Whether opting for a foldable model for ease of storage or a reinforced rigid box for heavy-duty use, the choices are plentiful and adaptable.

Choosing the right corflute box involves more than just picking a size or color. Here are critical factors Australian businesses should consider:

Determine if your boxes are for short-term transport, long-term storage, or display purposes. Outdoor uses require boxes with UV-resistant coatings, while indoor uses can prioritize lighter and cheaper options.

Thicker corflute sheets offer better protection but add cost and weight. Analyze your product’s fragility and shipping method to decide if 3mm is sufficient or if you need 6mm or more.

Many Australian companies benefit from customized printing on corflute boxes, which helps with branding or product information. You can also customize box dimensions, handles, lids, or partitions.

Australia has strict regulations and a strong focus on sustainability. Opt for recyclable corflute and suppliers who provide environmentally friendly solutions.

Evaluate suppliers for quality assurance, compliance with Australian standards, delivery timelines, and after-sales support. This is crucial whether purchasing locally or importing.

When it comes to corflute boxes, understanding the pricing landscape is essential for Australian businesses aiming to optimize their packaging costs. The following factors significantly influence the price of corflute boxes in the Australian market:

By carefully assessing these factors and balancing cost with quality and functionality, Australian businesses can make informed purchasing decisions that align with their operational needs and budgets.

Pricing is a significant factor for Australian businesses deciding where to purchase corflute boxes. Both options have distinct advantages:

China is a global manufacturing hub for corflute products, offering:

Australian suppliers offer:

The downside is often higher unit prices due to local production costs and smaller economies of scale.

Many Australian companies combine both strategies:

This hybrid approach optimizes cost without compromising supply chain flexibility.

Before placing an order, ensure you cover these crucial points:

Polyflute is a dedicated manufacturer specializing in corflute boxes with extensive experience serving international markets, including Australia. We provide customizable, high-quality corflute boxes designed to meet the stringent requirements of Australian businesses. Our commitment to quality, competitive pricing, and export readiness ensures that customers receive reliable packaging solutions tailored to their needs.

Corflute boxes continue to gain traction in Australia thanks to their durability, versatility, and eco-friendliness. Understanding the different types available, knowing how to select the right product, and analyzing price factors between Chinese imports and local Australian supplies can help businesses make cost-effective and efficient packaging decisions.

Whether you are in agriculture, manufacturing, retail, or logistics, corflute boxes offer an adaptable solution that meets Australian market demands. By partnering with experienced manufacturers like Polyflute, Australian companies can ensure they receive premium packaging products at competitive prices, suitable for the unique challenges of the region. Welcome to contact us for price list!