In modern supply chains, speed and accuracy are paramount. Every second counts in warehouse operations, especially during the picking process, where goods are selected from inventory to fulfill customer orders. As e-commerce and retail distribution continue to grow, efficient warehouse layouts and intelligent storage systems have become essential.

Among all the elements that influence picking efficiency, the picking bins for warehouse operations play an underrated but crucial role. These bins, boxes, and containers ensure that items are sorted, stored, and retrieved in the most streamlined way possible. Without properly chosen picking bins, warehouses risk increased picking times, inventory misplacement, and even workplace injuries.

This article dives deep into how picking bins shape the operational flow of modern warehouses, how to choose the right ones, and what kinds of warehouse picking bins and picking boxes for warehouse use are most effective for various industries.

Before selecting the ideal picking containers, it’s important to understand the different types of picking systems that define warehouse layouts. Picking refers to the process of collecting products from storage to fulfill customer orders, and there are multiple systems tailored to different inventory structures and operational models.

Manual picking is still widely used in small to medium-sized warehouses. Workers move through aisles with picking carts, guided by printed lists or mobile devices. This system offers flexibility but heavily relies on how items are stored and retrieved. In such settings, well-organized picking bins for warehouse use are critical to ensure that stock is accessible, sorted, and labeled correctly.

Automated picking systems, such as conveyor belts, robotic arms, and AS/RS (Automated Storage and Retrieval Systems), require specially designed containers that can integrate seamlessly with machinery. These often use standardized bin sizes made of durable plastics to ensure compatibility and reduce misalignment.

In any system, storage density and accessibility determine picking speed. If workers must dig through oversized or unlabeled boxes, picking time increases and accuracy suffers. That’s where customized warehouse picking bins help. Bins designed for specific products or order sizes ensure that items can be retrieved quickly, which is essential for just-in-time operations or 24-hour delivery warehouses.

The right bin also prevents damage to delicate goods like electronics, glass, or pharmaceuticals, making bin selection a vital part of inventory preservation.

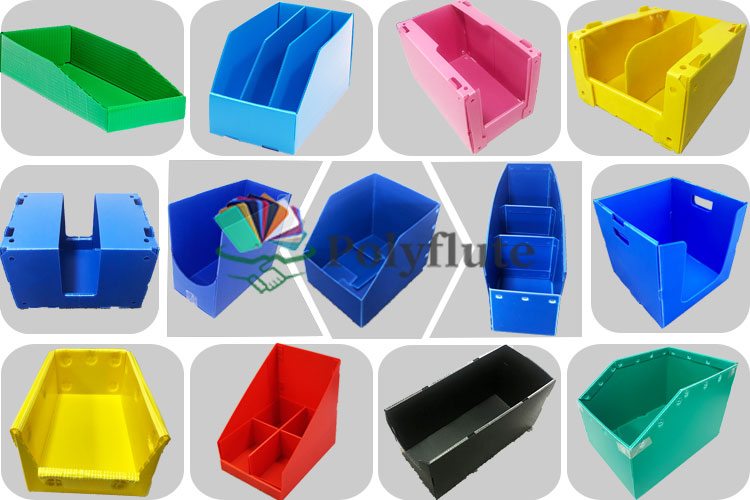

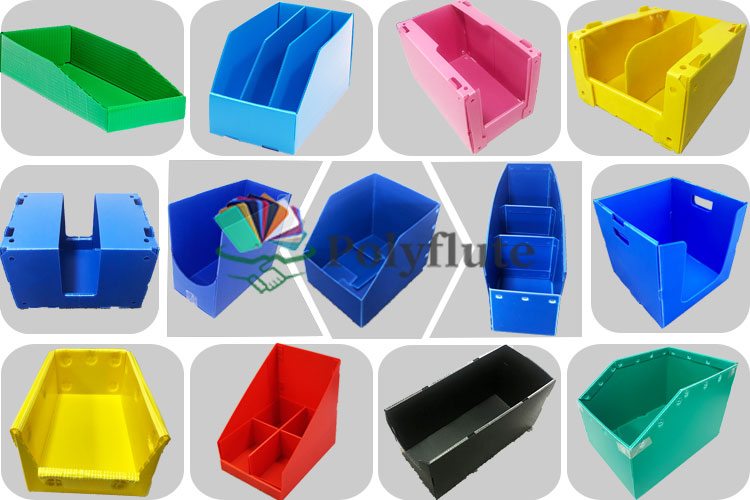

There’s no one-size-fits-all solution when it comes to picking bins for warehouse operations. Different industries, products, storage environments, and order fulfillment models require specialized bins designed to streamline workflows, improve organization, and boost picking speed.

Selecting the right type of bin can significantly reduce handling time, lower error rates, and even optimize warehouse space utilization. Below are the most common and efficient bin types used in warehouses today.

Open front bins are a go-to solution for many warehouse operations. These bins provide instant visibility and direct access to stored items, allowing pickers to retrieve products quickly without removing the entire bin from the shelf. Their ergonomic design makes them ideal for high-volume SKUs, parts with frequent turnover, or visually identified inventory like bolts, wires, and fasteners.

Commonly made from high-density polyethylene (HDPE) or polypropylene, these bins are available in vibrant colors for visual management and can be labeled or barcoded for enhanced inventory tracking. Open front bins are particularly useful in:

These two types offer different benefits, depending on your operational needs:

| Feature | Stackable Bins | Nestable Bins |

|---|---|---|

| Storage Efficiency | Use vertical space by stacking bins on top | Nest inside each other when empty |

| Handling | Stable when stacked; often interlocking | Lightweight; ideal for returns or unused stock |

| Ideal for | High-density storage environments | Seasonal or low-frequency stock rotation |

| Material | Heavy-duty plastic or metal | Lightweight plastic or hybrid materials |

Stackable bins are designed to create vertical storage columns, perfect for environments where shelving space is at a premium. Their reinforced walls and interlocking design keep them securely stacked, even when filled with heavier items.

Nestable bins, on the other hand, are invaluable for operations where bins are rotated regularly or returned empty. When not in use, they save up to 75% space by nesting within each other.

When pickers need to move through a large facility, mobility is key. Mobile picking carts with adjustable or modular bins bring storage directly to the picker, minimizing travel time. These setups are especially helpful in:

Some mobile solutions even include power-assisted carts with touchscreens, inventory scanners, and smart bin locking mechanisms to prevent mispicks during complex order consolidation.

Modern picking bins for warehouse systems are often integrated with warehouse management software (WMS), making accurate labeling a necessity. Bins with smooth surfaces and built-in label holders are perfect for barcode labeling, SKU tags, and even QR codes.

For higher-level automation, RFID-enabled bins are increasingly adopted. These bins feature embedded RFID chips or stickers that allow for:

RFID bins are commonly used in high-value inventory storage such as pharmaceutical and electronics warehouses.

Not all inventory fits neatly into standard containers. That’s why custom warehouse picking boxes are gaining traction among industries with special handling requirements. Customization options include:

For example, a warehouse storing surgical instruments may require bins that are both sterilizable and color-coded for different types of tools, while a frozen food distributor might use insulated bins rated for -30°C.

Picking bins come in a wide range of sizes to accommodate everything from small screws to large mechanical parts. Here are some of the most frequently used dimensions (in both inches and millimeters):

| Bin Type | Length x Width x Height (inches) | Dimensions (mm) | Common Use |

|---|---|---|---|

| Small Parts Bin | 10″ x 4″ x 4″ | 254 x 102 x 102 mm | Bolts, screws, electrical parts |

| Medium Picking Bin | 14″ x 8″ x 6″ | 356 x 203 x 152 mm | Tools, cables, spare parts |

| Large Open Front Bin | 18″ x 11″ x 10″ | 457 x 280 x 254 mm | Clothing, boxed items, large parts |

| Stackable Bin | 24″ x 16″ x 12″ | 610 x 406 x 305 mm | Bulk inventory, heavier items |

| Nestable Bin | 20″ x 14″ x 12″ | 508 x 356 x 305 mm | Returnable packaging, seasonal stock |

The cost of picking bins for warehouse use varies widely depending on size, material, design, and customization. Basic small plastic bins may start as low as $1.50 to $5 per unit, making them a budget-friendly choice for high-volume part storage. Stackable and heavy-duty bins typically range from $10 to $30 each, while mobile bin carts with wheels or modular setups can cost $100 or more. Custom warehouse picking boxes with RFID tags, anti-static materials, or insulated linings may range from $20 to $100+ depending on complexity and production volume, price details, welcome to contact Polyflute.

Buying in bulk often yields significant discounts, and some suppliers offer wholesale or tiered pricing. It’s also wise to consider lifecycle value—higher upfront costs for durable, reusable bins can result in lower long-term replacement expenses. Always evaluate cost in relation to picking speed, space optimization, and operational efficiency to get the best ROI from your bin investment.

Every warehouse has its own set of needs. Choosing the correct bin involves more than just selecting something that fits on a shelf. Here are several factors to consider:

Choosing bin sizes that align with your product dimensions and order volumes is essential. Overly large bins waste space, while bins that are too small may damage items or require multiple units for a single SKU.

Warehouses storing heavy tools, liquids, or sharp items should opt for bins made of HDPE or reinforced polypropylene. Meanwhile, warehouses handling food or pharmaceuticals need FDA-compliant plastic that can handle sterilization or refrigeration.

Bins at uncomfortable heights or poor angles can lead to repetitive strain injuries. Selecting picking bins with slanted fronts, hand grips, and adjustable positioning can dramatically improve picker comfort and reduce errors.

Clear plastic bins or colored bins with large label areas allow workers to identify SKUs quickly, improving speed and accuracy. Bins used in warehouse picking boxes systems should also support barcode or RFID tagging.

Your bin should be compatible with shelves, trolleys, or robots already in use. It’s important to check dimensions and weight tolerances before purchasing, especially for automated or multi-tier systems.

A mid-sized e-commerce fulfillment center in California optimized their operations by investing in stackable open front picking bins for warehouse use. By color-coding bins based on product type and adding mobile picking carts, their picking speed increased by 32%, and picking errors dropped by 17%.

A pharmaceutical distributor needed ultra-hygienic picking boxes for warehouse use. By switching to antibacterial, label-ready bins with RFID tracking, they reduced mispicks to near zero and ensured compliance with health regulations.

An industrial parts warehouse handling vehicle components used reinforced warehouse picking boxes to prevent bin breakage. The bins were customized with foam interiors to cushion sensitive electronic components, resulting in a 40% drop in product damage during order processing.

Choosing the right picking bin is just step one. Maintaining them ensures consistent performance and avoids operational delays.

Dust, debris, and wear can reduce bin performance. Regular cleaning, especially for food or medical storage, helps prevent contamination. Check bins for cracks, warping, or label fading every month.

Bins often get re-used for different products. It’s essential to use removable labels or digital tagging to prevent misidentification.

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) systems require strategic bin usage. Label bins accordingly and rotate older bins into easier-to-reach positions to manage expiration-sensitive products.

Modern picking bins for warehouse use are often integrated with warehouse management systems (WMS). Use bins with barcode or RFID features that can sync directly with your system to automate inventory updates.

Choosing where to source your bins is as critical as the bins themselves.

Platforms like Uline, Global Industrial, and Amazon offer a wide range of picking bins for warehouse use. They allow you to compare prices, read reviews, and check compatibility specs.

Local vendors can offer faster shipping and easier returns. However, if you’re looking to buy in bulk, overseas manufacturers — especially from China or India — may provide competitive pricing on warehouse picking bins.

For specialized industries, custom bin manufacturers can create picking boxes for warehouse use tailored to your SKU dimensions, handling needs, and environmental conditions.

In the fast-paced world of logistics and fulfillment, efficiency isn’t a luxury — it’s a necessity. Whether you’re running a regional distribution center or a global shipping hub, choosing the right picking bins for warehouse operations directly impacts your bottom line.

By understanding your picking system, evaluating your inventory, and selecting bins based on functionality and ergonomics, you can dramatically improve your warehouse’s productivity and accuracy. Invest in the right bins today, and set your warehouse up for success tomorrow. Contact Polyflute for quotations about different types of picking bins for warehouse right now!