In the world of modern packaging, businesses are increasingly turning to smart, reusable, and sustainable solutions. One such innovation that is rapidly gaining traction is corrugated plastic boxes with dividers. These boxes are a game-changer for industries that require safe, clean, and efficient methods of transporting and storing items. Designed for maximum durability and protection, they cater to a wide array of applications from automotive to pharmaceuticals, electronics to agriculture.

In this comprehensive guide, we’ll explore the advantages of corrugated plastic boxes with dividers, delve into their types and applications, provide pricing insights, and offer practical tips on how to choose the right configuration for your business needs. We will also briefly mention our company, Polyflute, a manufacturer committed to high-quality corrugated plastic solutions.

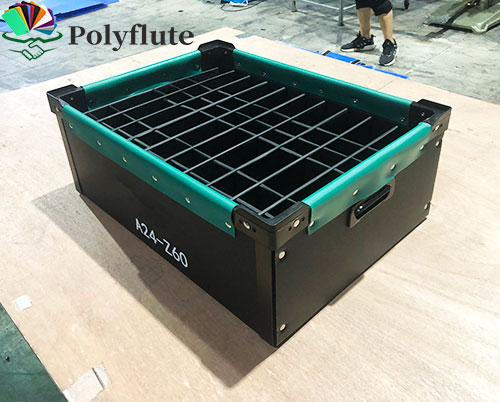

Corrugated plastic boxes with dividers are storage or shipping containers made from corrugated polypropylene or polyethylene plastic materials. These boxes incorporate inner divider sheets that section the box into smaller compartments. The dividers can be customized to suit various item shapes and sizes, ensuring items remain separate, organized, and undamaged during handling and transportation.

Unlike cardboard or wooden alternatives, corrugated plastic offers advantages such as water resistance, chemical resistance, and reusability. The addition of dividers enhances their utility, especially for fragile or sensitive components.

Corrugated plastic boxes with dividers come in various structural and functional designs, each tailored to specific storage, transport, or operational requirements. The choice of box type often depends on the type of items being stored or shipped, the handling environment, and space-saving considerations. Below are some of the most widely used types, along with their typical applications across different industries.

Standard tote-style corrugated plastic boxes with fixed dividers are among the most commonly used in industrial settings. These boxes feature built-in, non-removable divider sheets that segment the interior into uniform compartments. The fixed dividers provide a rigid structure that prevents parts from moving during handling or transportation.

Key Features:

Common Applications:

These boxes offer both flexibility and space efficiency. When not in use, they can be collapsed flat, which is particularly useful in operations where return logistics or seasonal storage is involved. The dividers in these boxes are removable, allowing users to adjust the number and size of compartments based on the stored items.

Key Features:

Common Applications:

Stackable corrugated plastic boxes with dividers are engineered for high-density storage environments. They typically include interlocking lids or bases that ensure stable stacking. The interior dividers remain secure during stacking, maintaining compartmental integrity and preventing damage due to compression.

Key Features:

Common Applications:

For industries dealing with electronic components, electrostatic discharge (ESD) can cause irreversible damage. Conductive or anti-static corrugated plastic boxes are made from materials that dissipate or shield against static electricity. These boxes often feature divider sheets made from the same protective material.

Key Features:

Common Applications:

When standard solutions fall short, custom-engineered corrugated plastic boxes with dividers offer a tailored approach. These can include dividers of varying heights, widths, or materials. Some even incorporate foam inserts, Velcro straps, or layered compartments to ensure the utmost security of high-value or fragile items.

Key Features:

Common Applications:

The two most common materials are:

These materials can be extruded into corrugated sheets that are then die-cut and formed into box structures.

In addition to complete boxes, many users also purchase corrugated plastic divider sheets separately. These sheets serve as internal partitions or protective layers between product levels inside a single box. They can be scored, slotted, or welded to create compartments and are compatible with various box types.

The cost of corrugated plastic boxes with dividers can vary significantly depending on several key factors, including the size of the box, the type and complexity of the divider system, material thickness (usually measured in millimeters), customization requirements, order volume, and whether additional features such as anti-static properties or branding are included.

Standard Tote Boxes with Fixed Dividers:

These are typically the most economical option. For bulk orders, prices may start from $2 to $6 per unit, depending on the size and compartment count.

Collapsible or Stackable Boxes with Dividers:

Due to the added functionality and structural reinforcement, these boxes usually range between $6 to $15 per unit in large quantities.

Conductive or Anti-Static Boxes with Dividers:

Specialized ESD-safe materials increase the price, often ranging from $10 to $25 per unit, especially for electronic-grade applications.

Custom Engineered Solutions:

Fully tailored boxes with foam inserts or non-standard dimensions can cost $20 to $50 or more per unit, particularly for low-volume or high-complexity orders.

It’s also important to note that large-scale buyers or long-term supply agreements often benefit from significant discounts. As a manufacturer, Polyflute offers competitive pricing structures based on order size, customization level, and logistical requirements. Bulk orders and repeat business typically enjoy preferential rates and faster lead times.

Selecting the right corrugated plastic boxes with dividers for your business isn’t simply a matter of picking a size or color — it’s about matching the box’s structure, material, and compartment design to your specific operational needs. Making the right choice can significantly improve handling efficiency, protect delicate items, and reduce overall packaging costs.

The size, shape, weight, and fragility of your items should directly influence the choice of box and divider configuration. For example:

Measure the largest and smallest item dimensions in your product mix, then design or choose a box that offers both efficient compartmentalization and enough room for easy loading and unloading.

Dividers can be fixed (integrated into the box structure) or removable (inserted as needed).

In some cases, foam inserts or layered trays can be added to provide shock absorption or stackable storage for multi-level organization.

Think about where and how the boxes will be used. Key environmental factors include:

Understanding your operational environment ensures you choose boxes that will last longer and perform reliably.

For operations that rely on vertical stacking or pallet-based movement, it’s crucial to select boxes with stackable designs and secure lids. Some stackable boxes come with interlocking grooves to prevent shifting during transport.

If boxes will be used in closed-loop logistics or returnable packaging systems, collapsible or nestable designs should be prioritized to reduce return freight costs.

Polyflute, for instance, offers both standardized and fully customized corrugated plastic boxes with dividers, and can assist with design consultation based on your specifications.

Don’t focus solely on the unit price. Consider:

Often, investing slightly more upfront in the right configuration results in long-term cost savings and smoother operations.

Polyflute is a leading manufacturer of high-quality corrugated plastic packaging, including corrugated plastic boxes with dividers. We offer a wide variety of customizable solutions for different industry needs. Our production capabilities allow us to deliver consistent, durable, and cost-effective packaging with minimal lead times.

Whether you’re managing an industrial supply chain or organizing small parts in a workshop, corrugated plastic boxes with dividers offer an unmatched combination of strength, flexibility, and efficiency. With numerous types to choose from and the option for full customization, these boxes are an investment in both product safety and operational efficiency.

Choosing the right box involves evaluating your specific needs, considering the types of dividers required, and understanding your environment’s demands. With the right information and a trusted manufacturer like Polyflute, you can enhance your packaging strategy and improve overall productivity.

If you’re in the market for durable, customizable, and reusable packaging, corrugated plastic boxes with dividers should be at the top of your list. Feel free to contact Polyflute for price list of these boxes right now!