In the world of transparent plastic materials, two contenders dominate the market: polycarbonate sheets and acrylic sheets. These thermoplastic materials are widely used across various industries, including construction, automotive, signage, electronics, and DIY projects. When it comes to choosing between the two, many professionals and consumers find themselves asking, “Which is better—polycarbonate or acrylic?”

This question isn’t just about personal preference. The decision between polycarbonate and acrylic sheets can have significant implications for durability, safety, clarity, cost, and environmental impact. Each material has its own strengths and weaknesses, and selecting the right one depends on understanding these differences in depth.

In this comprehensive guide, Polufulte will delve into the intricate comparison of polycarbonate sheet vs acrylic sheet, analyzing everything from physical properties and manufacturing processes to cost-effectiveness and ideal applications. By the end, you’ll have a clear understanding of which material best suits your needs.

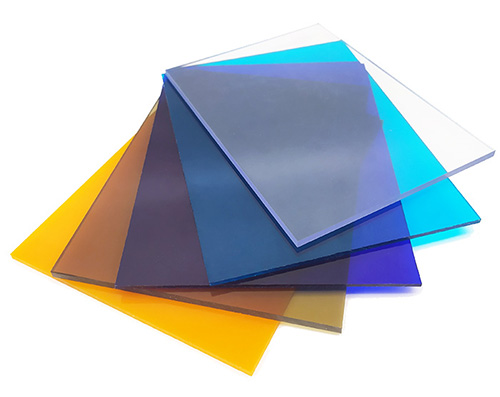

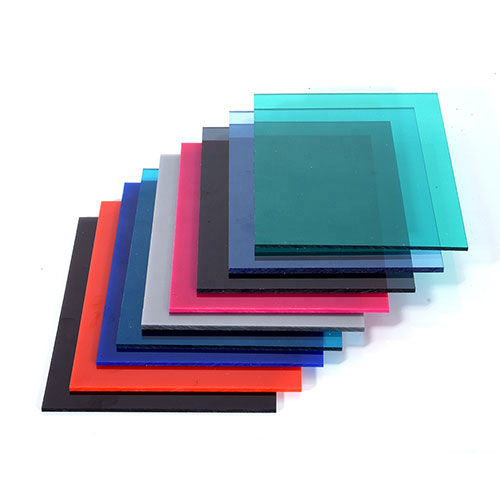

Polycarbonate is a thermoplastic polymer containing carbonate groups in its chemical structure. It is known for its exceptional impact resistance, optical clarity, and high-performance characteristics under various environmental conditions. Polycarbonate sheets are manufactured through an extrusion process where molten polycarbonate resin is forced through a die to form sheets of desired thickness.

Key Features of Polycarbonate Sheets:

Acrylic, also known as PMMA (Polymethyl Methacrylate), is another transparent thermoplastic that rivals glass in terms of clarity and aesthetics. It is typically produced using cast or extruded methods. Acrylic is less impact-resistant than polycarbonate but offers superior surface hardness and better optical clarity.

Key Features of Acrylic Sheets:

Both polycarbonate & acrylic sheets are excellent alternatives to glass, but their unique properties make them more suitable for specific use cases. Understanding their core differences is essential before making a purchase decision.

When comparing acrylic sheet vs polycarbonate, it’s important to assess how each performs under real-world conditions.

Polycarbonate clearly outperforms acrylic in terms of impact resistance. It is virtually unbreakable and is often used in bulletproof windows, riot shields, and protective gear. Acrylic, while 10–20 times more impact-resistant than glass, can still crack or shatter under high stress.

While both materials offer high light transmission, acrylic has the upper hand in terms of optical clarity. It provides a crystal-clear view without distortion, making it ideal for display cases and picture frames. Polycarbonate may have a slight tint and is more prone to yellowing over time without UV treatment.

Acrylic is naturally UV-resistant, which makes it suitable for outdoor applications without the need for additional coatings. Polycarbonate requires UV coatings to prevent degradation and yellowing.

Both materials are lighter than glass, but polycarbonate is more flexible, allowing it to be bent or cold-formed without cracking. Acrylic is more rigid and can snap under pressure if not properly handled.

Acrylic is more scratch-resistant than polycarbonate, making it better suited for applications where aesthetics and surface appearance are important.

By evaluating these attributes, one can determine whether acrylic sheets vs polycarbonate are more appropriate for specific environments and functional demands.

Another key factor in the acrylic sheet or polycarbonate debate is the ease with which each material can be processed and fabricated.

Both materials can be cut using standard tools such as table saws, routers, and laser cutters. However, acrylic sheets can crack if not properly supported during cutting, while polycarbonate is more forgiving due to its flexibility.

Polycarbonate is easier to bend, even at room temperature, and is preferred for curved surfaces. Acrylic requires heat to bend and is more prone to stress fractures.

Acrylic can be bonded with solvents for a seamless, clear finish. Polycarbonate requires specialized adhesives and may exhibit stress cracking if improperly bonded.

Acrylic can be polished to a high gloss finish, while polycarbonate is more difficult to polish and is often treated with abrasion-resistant coatings to improve durability.

Overall, polycarbonate is easier to manipulate in dynamic shapes, whereas acrylic offers better finishes and detailing. Choosing between them in terms of fabrication depends on the desired end-product and processing capabilities.

When evaluating materials for safety, especially in high-impact or high-risk applications, polycarbonate sheet vs acrylic sheet is a critical consideration.

Polycarbonate does not shatter and is ideal for security windows, machine guards, and protective panels. Acrylic, although stronger than glass, can shatter under high stress, potentially creating sharp fragments.

Polycarbonate has a higher heat resistance threshold (up to 115°C) compared to acrylic (around 80°C), making it more suitable for environments with fluctuating or high temperatures.

Acrylic offers better resistance to chemicals and solvents, which is important in industrial settings. Polycarbonate can be affected by certain chemicals and may require protective coatings.

Polycarbonate generally has a better fire rating and is often classified as flame retardant. Acrylic tends to melt and drip when exposed to flames and has a higher flammability index.

For safety-critical environments, polycarbonate offers a higher margin of durability and resistance to external stressors.

In any project, budget constraints are crucial. So how do acrylic sheets vs polycarbonate compare in terms of cost?

Acrylic sheets are generally 30–40% less expensive than polycarbonate, making them an economical option for applications where impact resistance is not a primary concern.

Polycarbonate may require specialized handling and tools, which can raise installation costs. However, its longer lifespan and resistance to breakage often result in lower maintenance and replacement expenses over time.

When properly maintained and UV-protected, polycarbonate sheets can last up to 20 years. Acrylic typically has a lifespan of 10–15 years, depending on environmental exposure.

For long-term ROI, polycarbonate may offer better value despite a higher upfront cost.

With increasing emphasis on sustainability, understanding the ecological impact of materials is crucial.

Both acrylic and polycarbonate are recyclable, but they require different processes. Acrylic can be depolymerized and reused effectively, whereas polycarbonate recycling involves more complex chemical procedures.

Acrylic has a relatively lower carbon footprint during production compared to polycarbonate. However, polycarbonate’s longevity may offset its higher production emissions over its lifespan.

Manufacturers are increasingly offering environmentally certified versions of both materials, including bio-based acrylics and low-emission polycarbonates.

For eco-conscious buyers, weighing recyclability, longevity, and carbon output is essential when deciding what is the difference between acrylic and polycarbonate sheets in sustainability terms.

Choosing the right material often boils down to its suitability for specific applications.

This side-by-side look at use cases solidifies the importance of understanding polycarbonate sheet vs acrylic sheet from an application-based perspective.

If you’re struggling with choosing acrylic sheet or polycarbonate, consider the following checklist:

RequirementBest Choice

High impact resistance Polycarbonate

Optical clarity Acrylic

Outdoor longevity Acrylic (UV stable)

Scratch resistance Acrylic

Bendability Polycarbonate

Cost efficiency Acrylic

Fire resistance Polycarbonate

Use this table as a quick reference when planning your next project.

The debate of polycarbonate sheet vs acrylic sheet doesn’t yield a one-size-fits-all answer. Each material brings its own unique strengths to the table, and your specific application needs should guide your choice.

Choose polycarbonate when durability, safety, and impact resistance are your top priorities. Opt for acrylic if you need a crystal-clear finish, scratch resistance, and a budget-friendly alternative.

Both materials represent high-performance, flexible options in today’s world of transparent plastics. With this guide in hand, you can make an informed, confident decision tailored to your project’s requirements.

Q: What is the difference between acrylic and polycarbonate sheets?

A: Acrylic is more transparent and scratch-resistant, while polycarbonate is more impact-resistant and flexible. Your choice should depend on your need for clarity vs. durability.

Q: Is acrylic cheaper than polycarbonate?

A: Yes, acrylic is generally 30–40% less expensive than polycarbonate.

Q: Can both materials be used outdoors?

A: Yes, but polycarbonate requires UV protection to prevent yellowing, while acrylic is naturally UV-resistant.

Q: Which one is safer?

A: Polycarbonate is safer in high-impact scenarios due to its shatterproof nature.