In the world of plastic-based materials, few comparisons are as relevant and widely debated as PVC foam board vs PVC board. These two materials, though sharing the same base polymer (polyvinyl chloride), serve very different roles across industries ranging from advertising to construction. Understanding their characteristics, performance differences, cost implications, and environmental impacts is critical for making an informed choice.

As a leading manufacturer of PVC foam board, Poyflute is proud to contribute its industry knowledge to this in-depth comparison. Here we will comprehensively compare PVC foam board and PVC board in terms of composition, properties, availability, durability, cost-effectiveness and sustainability, so that you can have a better understanding of these two products. Poyflute’s years of experience in developing, manufacturing, and supplying high-quality PVC foam boards make us a trusted source for those seeking reliable plastic solutions.

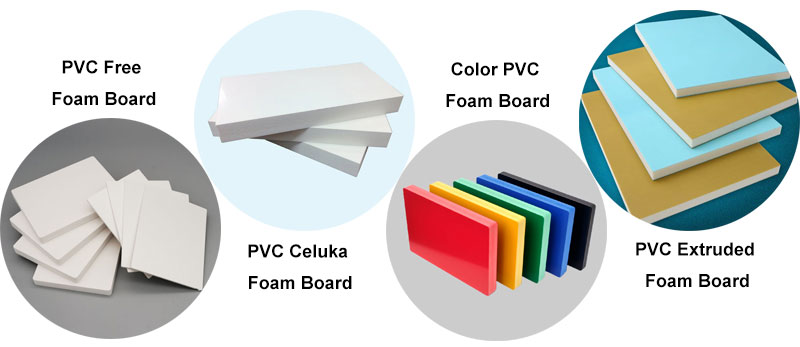

PVC foam board is a lightweight, expanded form of polyvinyl chloride. It’s created by mixing the PVC compound with a blowing agent, which results in a foamed core sandwiched between solid outer surfaces. This unique structure provides both strength and reduced weight.

The foam core gives it a less dense, more compressible feel, while still maintaining rigidity. Poyflute’s PVC foam boards are manufactured with precision to maintain a fine cell structure and smooth surfaces, ensuring excellent printability and mechanical performance. Our proprietary manufacturing process ensures the boards are dimensionally stable, durable, and easy to fabricate.

PVC board, sometimes referred to as solid PVC or rigid PVC, is made from unfoamed PVC material. It is dense, heavy, and highly durable. Unlike its foamed counterpart, solid PVC board does not contain any air pockets and thus has higher tensile strength, better impact resistance, and greater structural stability.

Solid PVC is ideal for demanding applications such as chemical processing plants, outdoor construction projects, and areas exposed to moisture or mechanical stress.

| Property | PVC Foam Board | PVC Board |

|---|---|---|

| Density | Low | High |

| Weight | Lightweight | Heavy |

| Flexibility | Moderate | Low (Rigid) |

| Tensile Strength | Moderate | High |

| Surface Finish | Smooth or Textured | Smooth |

| Moisture Resistance | High | Very High |

PVC foam board’s lower density makes it much easier to handle, transport, and install. It also supports a wider range of decorative applications, such as laminating, painting, and digital printing. On the other hand, PVC board is more robust and is preferred for heavy-duty environments that require high impact strength and rigidity.

Poyflute ensures all physical specifications of our PVC foam boards meet industrial and creative standards. Whether for signage or interior decor, the structural consistency of our products stands out.

PVC foam board is widely used across many sectors due to its versatility:

At Poyflute, our PVC foam boards are engineered to support all these applications, offering superior bonding surfaces and consistency across panels. We work closely with signage companies, architects, and furniture makers to deliver solutions that fit their exact specifications.

PVC board, due to its structural integrity, is favored in heavy-duty environments:

Though Poyflute specializes in PVC foam board, we understand the complementary role of solid PVC boards in these sectors and can help customers distinguish the most suitable material for their needs.

PVC foam board can be cut, drilled, routed, and shaped using conventional woodworking tools. It does not splinter and is less likely to crack during machining. This makes it ideal for CNC cutting and laser engraving.

Poyflute’s foam boards are manufactured to tight tolerances, allowing for precision fabrication that is essential in signage and customized decor.

PVC board, due to its hardness, requires more robust tools and generates more wear on blades. While it can be fabricated, it’s less suited to fine detailing or artistic designs.

PVC foam board bonds well with various adhesives and can also be nailed or screwed without splitting. Poyflute’s proprietary surface treatment ensures stronger adhesive bonding for print and lamination.

PVC board provides excellent screw retention and is often welded or chemically bonded for permanent installation.

At Poyflute, we prioritize sustainability by using eco-conscious raw materials and implementing energy-efficient production processes. Our PVC foam boards are fully recyclable and generate minimal waste during production, making them a preferred choice for businesses aiming to reduce their environmental footprint. Additionally, the lightweight nature of PVC foam board helps reduce transportation emissions, contributing further to its environmental benefits.

PVC board, while also recyclable, generally requires more energy to produce due to its higher density and solid structure. For projects with strict sustainability goals, PVC foam board may therefore be the better choice.

As part of our commitment to the environment, Poyflute continuously invests in greener technologies and participates in recycling programs to promote circular use of plastic resources.

PVC foam board is typically less expensive to manufacture due to its lower material density and simpler processing. The foaming process allows manufacturers to use less raw PVC per unit of volume, significantly reducing costs.

Poyflute’s foam board solutions are cost-optimized without compromising quality, making them ideal for price-sensitive projects in advertising and interiors.

In contrast, PVC board requires more raw material and energy-intensive manufacturing equipment. This makes the cost per unit higher, especially for thicker panels and specialized grades used in industrial applications.

Due to its lighter weight and ease of cutting, PVC foam board significantly reduces labor and installation costs. It requires less manpower and minimal specialized tools, making it especially economical for large-scale projects such as advertising campaigns or interior renovation.

PVC board’s heavier nature means it can incur higher shipping costs and require more robust mounting systems. Additionally, installation often involves more time and effort, further increasing overall expenses.

PVC board outperforms foam board in terms of structural durability and longevity, particularly in heavy-duty or load-bearing applications. It can withstand higher mechanical stress, extreme weather conditions, and prolonged exposure to chemicals, making it suitable for long-term industrial or structural uses.

However, PVC foam board still offers substantial durability in indoor or controlled environments. When used appropriately, it can last for years with minimal maintenance. Poyflute’s engineered foam boards are UV-resistant, mold-resistant, and tested for performance longevity under standard commercial usage.

Both types of board are low-maintenance materials. PVC foam board resists moisture, mold, and mildew, requiring only occasional cleaning with mild detergent and water.

PVC board offers similar maintenance benefits but also has greater resistance to physical wear and tear, making it ideal for high-traffic areas or environments with demanding hygiene requirements.

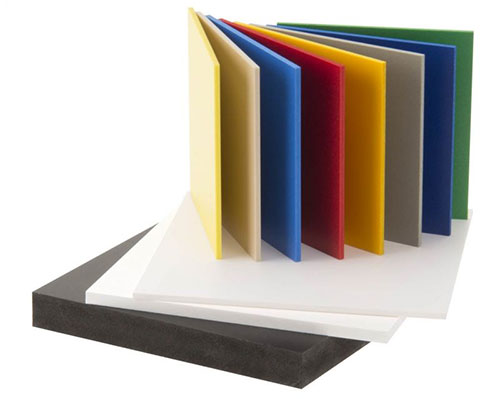

PVC foam board stands out for its versatility in aesthetic applications. It is available in various finishes (matte, gloss, textured), thicknesses, and colors, and can be easily painted, laminated, or printed on. This makes it a favorite for signage, exhibition panels, and custom decorative elements.

At Poyflute, we offer PVC foam boards that are specifically engineered to meet the visual and functional demands of creative professionals. Our boards support high-resolution digital printing and are ideal for vibrant displays, making them a preferred choice in retail branding and visual merchandising.

PVC board, though more rigid and harder to manipulate for artistic purposes, is appreciated for its solid and clean appearance. It is often used where a strong, uniform visual is required, such as protective panels or lab equipment casings.

The growing popularity of PVC foam board is driven by industries such as advertising, interior design, and furniture manufacturing that increasingly value lightweight, cost-effective, and sustainable materials. As digital printing and CNC routing technologies evolve, PVC foam board has become even more accessible and practical for designers and fabricators.

PVC board remains crucial in construction, electrical, and chemical industries where mechanical integrity and resistance to harsh conditions are paramount. As infrastructure demands grow globally, the need for high-performance solid PVC panels continues to increase.

Furthermore, with increasing awareness around sustainability, manufacturers like Poyflute are investing in eco-friendly production technologies and circular economy practices. The shift towards green building materials is expected to further boost the market for lightweight, recyclable boards like PVC foam.

Choosing between PVC foam board and PVC board depends heavily on the application requirements. Here’s a quick recap:

| Feature | PVC Foam Board | PVC Board |

| Weight | Lightweight | Heavy |

| Rigidity | Moderate | High |

| Cost | Lower | Higher |

| Ease of Processing | High | Moderate to Low |

| Best for | Signage, Interiors, Models | Construction, Industrial Panels |

| Environmental Advantage | Higher (less material, lower transport impact) | Moderate |

Poyflute strongly recommends PVC foam board for businesses focused on creative applications, lightweight requirements, and sustainability. Our PVC foam board offers a well-balanced solution in terms of performance, aesthetics, and environmental impact.

In the detailed comparison of PVC foam board vs PVC board, it becomes evident that both materials have their distinct advantages and appropriate use cases. PVC foam boards outperform PVC boards in lightweight, aesthetic, and budget-sensitive projects, while PVC boards outperform PVC boards in terms of structural integrity and industrial resilience.

If you are looking for high-quality, reliable and environmentally friendly PVC foam board, Poyflute is definitely a trustworthy choice. We offer a variety of product types to meet a variety of different application needs. As a professional PVC foam board manufacturer, we always focus on combining quality and innovation, striving to provide customers with solutions that are more in line with practical needs, making it easier for you to find the right product for you.

Whether you are an architect, advertiser, fabricator, or industrial designer, understanding the nuances of PVC foam board vs PVC board will empower you to make optimal choices for your projects.

If you are looking for bulk PVC foam board, welcome to contact us to get factory price and more details right now!