Do you want to know the price of pp hollow sheet? Are you looking for pp hollow sheet manufacturer and supplier? Let’s get more by this article:

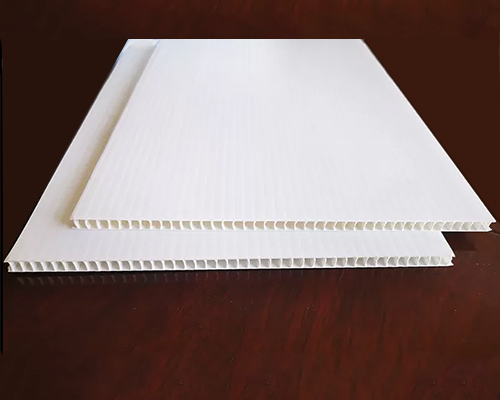

The PP hollow sheet has become a staple material in modern industrial packaging, advertising displays, construction partitions, and logistics applications due to its lightweight, strength, reusability, and recyclability. As demand increases across various sectors, one question remains central to buyers: What is the PP hollow sheet price? This article offers a deep-dive analysis of the PP hollow sheet price from various dimensions including material influence, thickness, specifications, functional requirements, and regional variations. Our goal is to provide you with a complete pricing roadmap that is both actionable and transparent in today’s market.

The PP hollow sheet price is not fixed; it varies based on several key factors. These components must be considered before quoting or ordering in bulk. Below, we break down the primary contributors that influence pricing across markets.

The core ingredient of PP hollow sheets is polypropylene, derived from petroleum-based raw materials. Global fluctuations in crude oil prices directly impact resin costs. In recent years, the polypropylene price per metric ton has ranged between $900 to $1,300, influencing the final pp hollow sheet price significantly.

The price difference between virgin and recycled PP sheets can be as much as 20-35%, making material choice a major consideration.

Thicker sheets mean more material per square meter, leading to a higher price. A 3mm sheet with a GSM of 550 will cost less than a 5mm sheet with a GSM of 1050. Below is a general price trend based on thickness:

ThicknessGSM RangeApproximate Price (USD/m²)

These are indicative prices for standard non-functional sheets in bulk orders (over 5,000m²). Smaller orders may incur a 10–20% premium.

Some applications demand PP sheets with additional functionalities, such as:

Adding such enhancements increases the pp hollow sheet price by 15%–50%. For instance:

| Feature | Extra Cost (% over base price) |

|---|---|

| UV Resistance | +15% |

| Anti-static | +25% |

| Flame-retardant | +30–50% |

| High Impact Grade | +20% |

Customized functionality comes at a cost, but it can be necessary depending on the use case.

Standard colors like white, blue, and black are often priced more competitively due to bulk availability. However, rare colors (e.g., orange, pink, corporate-matched tones) or color-matching requirements can lead to a 10%–20% price increase.

Printing logos, barcodes, or handling instructions through silk-screen or UV digital printing may add $0.10–$0.30 per sheet.

China dominates the PP hollow sheet export market, with average prices for general-purpose sheets ranging from $1.30 to $3.50/m², depending on thickness and features.

India offers competitive pricing at $1.50–$3.20/m², often used for agricultural, packaging, and signage applications. Turnaround times may be longer due to production load and domestic demand.

Due to import dependency, the pp hollow sheet price in these regions is generally higher — around $2.50–$4.50/m², including shipping, duties, and taxes.

In developed countries, PP hollow sheets are often distributed through wholesalers. Local prices range from $3.50 to $7.00/m², depending on the volume, regulatory compliance, and country-specific standards.

The distinction between wholesale and retail pricing is critical, especially for buyers on a budget or for startups testing materials in small quantities.

| Order Size | Average Price (USD/m²) | Remarks |

|---|---|---|

| < 500 m² | $3.50 – $5.00 | Includes packaging, shipping |

| 500 – 5000 m² | $2.50 – $3.20 | Mid-tier rates |

| > 5000 m² | $1.60 – $2.80 | Negotiated factory direct pricing |

Wholesalers often provide pricing tiers and discounts as order quantity increases. It’s worth noting that sheet dimensions also affect the per-unit cost. The most common sheet size globally is 1220mm x 2440mm.

4. Tips to Get the Best PP Hollow Sheet Price

While prices for PP hollow sheets are significantly influenced by market trends and dynamics, buyers can still optimize their purchasing strategy to secure the best value. Below are practical strategies to help minimize costs and improve overall purchasing decisions:

A. Buy Direct from Manufacturers

Going direct eliminates intermediary margins, such as those added by wholesalers or distributors. Purchasing from platforms like Alibaba, or even directly from factory websites, can reduce the PP hollow sheet price by up to 20%. In addition, working directly with manufacturers allows for clearer communication, the possibility of custom orders, and potentially more flexibility in terms of production timelines.

B. Use Standard Sizes and Colors

Sticking to standard sheet sizes (e.g., 1m x 2m, 1.22m x 2.44m) and colors (blue, black, white) can help avoid setup costs and reduce waste-related expenses. Custom sizes and unique colors often come with additional costs for setup, molding, and production adjustments. By choosing standard options, you can enjoy lower per-unit prices and quicker lead times.

C. Choose Functionality Wisely

Don’t over-engineer your purchase. While options like anti-static, UV protection, or flame retardant properties can be beneficial for specific applications, requesting enhancements that are not necessary for your needs can drive up the price significantly. Assess the functional requirements of your project and only request the enhancements that add value to your intended use, avoiding unnecessary expenses.

D. Order in Bulk and Plan Ahead

Consolidated orders allow manufacturers to optimize production and logistics, passing on the savings to the buyer. Bulk purchasing helps reduce costs per unit by minimizing production time, shipping, and handling expenses. Additionally, planning ahead and forecasting future demand can protect against price surges caused by seasonal fluctuations or material shortages. By anticipating needs and placing bulk orders in advance, buyers can lock in lower prices and ensure availability.

E. Negotiate Based on Usage Cycles

Long-term buyers or businesses with repeat needs can establish annual contracts or negotiate special rates based on forecasted usage. Suppliers are often more willing to offer favorable prices for customers who commit to larger volumes or long-term relationships. This strategy locks in a favorable PP hollow sheet price for the year, reducing the risk of price fluctuations and ensuring consistency in supply.

F. Consider Alternative Shipping Methods

Shipping costs can significantly impact the final price of your PP hollow sheets. If possible, consider alternative or more economical shipping methods, such as freight consolidation or regional shipping options. Opting for local suppliers or nearby manufacturing facilities can help save on shipping costs and reduce delivery time, which could result in more cost-effective purchases.

G. Evaluate Total Cost of Ownership

When assessing PP hollow sheet prices, consider the total cost of ownership rather than just the upfront price. This includes factors such as maintenance, longevity, and potential energy savings (if used in roofing or insulation applications). Sometimes a slightly more expensive sheet with better durability and functionality may save money in the long run due to lower maintenance or energy costs.

The pricing of PP hollow sheets in the coming years will be influenced by several key factors. As we look towards 2025–2026, it’s crucial for industry professionals and buyers to stay informed about market dynamics that could impact costs. Here’s a closer look at the expected trends:

A. Raw Material Price Volatility

The global resin market is expected to remain volatile in 2025–2026, meaning the price of PP hollow sheets will continue to fluctuate. Factors such as geopolitical events, oil price swings, and disruptions in the supply chain may cause uncertainty in the availability and pricing of polypropylene. Buyers should regularly monitor polymer indexes and market trends to make informed purchasing decisions and avoid unexpected price hikes.

B. Eco-Friendly Alternatives Driving Cost

Sustainability efforts have led to the increased use of recycled PP, which could drive prices slightly lower in certain segments. As environmental concerns grow, more manufacturers are adopting greener production processes. While recycled materials help reduce production costs, the process of sourcing, certifying, and controlling the quality of recycled PP might increase costs in the short term. However, as demand for eco-friendly alternatives rises, economies of scale may eventually reduce these costs.

C. Automation in Production

As production facilities in China and India continue to embrace automation, per-unit labor costs are expected to fall, making PP hollow sheet pricing more competitive over time. Automation increases efficiency, reduces human error, and lowers labor expenses, which directly impacts the overall cost of production. This trend is particularly relevant for manufacturers looking to scale production while maintaining cost-effectiveness.

D. Regional Supply Chain Shifts

With global freight routes stabilizing post-COVID, delivery times and shipping costs are decreasing, helping stabilize global PP hollow sheet prices across continents. As transportation networks improve and supply chains become more efficient, manufacturers can expect more consistent pricing. Additionally, regional supply chain shifts and the growth of local manufacturing could help mitigate shipping delays and reduce the reliance on international imports, further promoting cost stability.

E. Technological Advancements in Material Properties

Ongoing research into improving the mechanical properties and durability of PP hollow sheets may lead to the development of stronger and more cost-efficient products. Innovations such as enhanced UV resistance, better insulation properties, or higher load-bearing capabilities could become standard in the market, which could potentially raise prices in the short term but offer long-term benefits for buyers seeking higher-quality, durable solutions.

Understanding the true nature of pp hollow sheet price involves analyzing not just the cost per square meter but the entire ecosystem—materials, functionality, logistics, and market dynamics. Whether you’re a logistics coordinator sourcing packaging material, a manufacturer integrating PP sheets into your product line, or a trader comparing regional markets, making informed decisions about PP hollow sheet pricing can result in substantial savings.

Remember that cheapest isn’t always best. Balance price with performance, durability, and supplier reliability to get the most value out of every square meter.

If you’re looking to source PP hollow sheets at competitive prices, consider partnering with a trusted and experienced manufacturer like Polyflute. Established in 2005, Polyflute is a leading corrugated plastic sheet manufacturer in China with over 20 years of expertise and a monthly output capacity of up to 1,500 tons. All our products are fully customizable to meet your specific needs, and our commitment to quality is backed by certifications such as SGS, CE, and ISO 9001. Get in touch with us today to discover reliable, high-quality solutions tailored to your business.