Many of our customers are very interested in the question of how to bend corrugated plastic sheet. If you also really want to know how to bend corrugated plastic sheet, I believe I will give you a very satisfactory answer after reading the whole article.

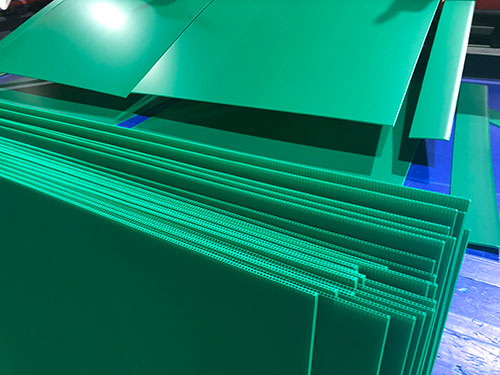

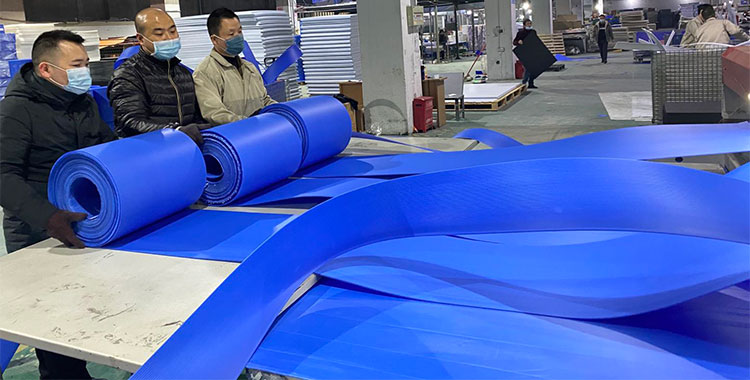

Corrugated plastic board is a plastic product that can meet the needs of various industries, and is often used in applications such as outdoor signs, sapling protection, floor protection, layer pads and various packaging boxes. The raw material of PP corrugated sheet is environmentally friendly and non-toxic polypropylene, which is an affordable and lightweight material. Since the structure of polypropylene corrugated plastic sheet is a hollow grid, it is very easy to bend or fold along the lines! In short, the thinner the sheet, the easier it is to bend, which is why many customers wholesale 2mm correx sheets from Polyflute are packaged and shipped in coils.

Corrugated plastic sheets are also known as coroplast sheets, correx boards, corflute sheets, danpla boards, PP hollow boards, etc. It is famous for its remarkable advantages such as moisture-proof, flame-retardant, friction-resistant, UV-resistant, and corrosion-resistant!

Polyflute coroplast supplier has a complete quality management system, all products have passed the ISO9001 quality system certification, and the market share is increasing year by year. We regard reputation first, quality first, mutual benefit and common development as the basis of our cooperation with customers. We have been trying our best to provide every customer with high-quality corrugated plastic products at reasonable prices and professional services.

If you want to bulk customize bent corrugated plastic sheets or want to know more details about how to bend corrugated plastic sheet, please feel free to contact us. You can fill out the form below, or email us, we will get back to you as soon as possible!

Q: So maybe I’ll try bending it around a pipe? Then it won’t be a crease, but it’ll be nice and rounded.(Retrieved from https://ecomodder.com/forum/showthread.php/coroplast-kammback-joining-bending-9225.html)

A: Thanks I spent a lot of time getting ready, now I really want to get as much done as possible before our long trip to Romania in mid-August.

I have *no* idea if this would work, but I was thinking of using a metal pipe and a heat gun. The heat gun would be aimed *into* the pipe to heat it up. If you were lucky, you could get it to have uniform heat. Hmmm, probably have to take turns heating the pipe from each end to maintain pseudo-uniformity.

But the other methods stated are proven

Q: I’m trying to bend the sheet around a curve but it’s not the direction that you usually would bend it. Can I heat it up or is there some other method that people use?

A: The answer to your question is ‘Very carefully’ of course. (Retrieved from https://www.rcgroups.com/forums/showthread.php?103187-How-do-I-bend-coroplast)

My experience is that some form of support is needed to keep one surface away from another. This is easy enough to do and need not involve any hi-tech methods.

For example, on my Zugini wing, the span versus chord is quite high (high aspect ratio) which means the wing would be very flexible and would not hold the section towards the tip. A simple beam of Correx with the flutes vertical, but bent into a ‘U’ shape will keep the top and bottom apart and stiffen the wing. It needs accuracy to bend each side in one go – in the same way as the l/e bends need doing. Use contact adhesive to glue it up.

The bending ability across the flutes is like leaning out of a window – you can only go so far. A stress reducing support – like that on my wing, helps without putting all the stress on one point. I’ve not been able to successfully heat and bend the stuff, and haven’t seen anyone else manage it. The whole point of it was to be stiff and light – other materials may be better at bending but not being stiff.

The real problem, which I suspect is what you’re getting at, is the ’round fuselage, tapering gradually at each end’. Some use of strategically placed formers help here too. However you need some careful mitreing of butt joints to get it to look tidy. and the taping also needs careful thought to avoid creasing.