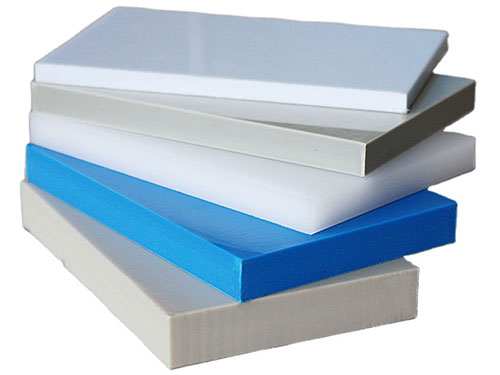

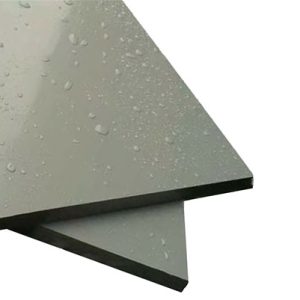

The polypropylene panels are produced by flat slot extrusion of granules obtained by the polymerization of propylene. It is a widely used plastic sheet. Today, it is the most in-demand modern plastic today due to its excellent consumer properties and wide range of uses. Sheets made from polypropylene homopolymers (where the macromolecules contain the same monomer units) have high flexural strength and operating temperatures from -5 to +105 degrees.

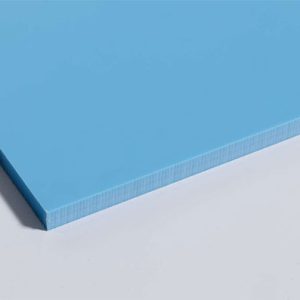

Block copolymers (copolymers) of propylene and ethylene are used to produce sheet plastics with high impact resistance (at low temperatures), improved long-term thermal stability and resistance to thermo-oxidative damage during operation. The operating temperature of these sheet products is -40 to +80 degrees.

Polypropylene (block copolymer) sheets are characterized by high rigidity, high strength, especially at low temperatures, good abrasion resistance and resistance to stress corrosion cracking. PP is characterized by good electrical insulation properties, high chemical resistance and low vapor and gas permeability over a wide temperature range. The operating temperature for sheet products is -40 to +80 °C. Polyflute can produce PP sheets in various colors according to customer requirements. UV stabilization possible.

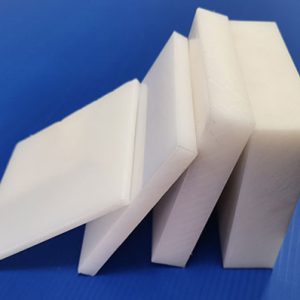

Polypropylene panels (homopolymer) are characterized by high impact and flexural strength, good abrasion resistance and stress corrosion cracking resistance. PP is characterized by good electrical insulation properties, high chemical resistance and low vapor and gas permeability over a wide temperature range. The operating temperature for sheet products is -5 to + 105 °C. Polyflute can produce PP plastic sheets in various colors according to customer requirements. UV stabilization is possible.

Polyflute® company manufactures and sells polypropylene panels of its own production. With 17+ years of successful export, we have produced more than 29,000 tons of products, improved the production process (extrusion method), and won the trust of 150+ old customers.