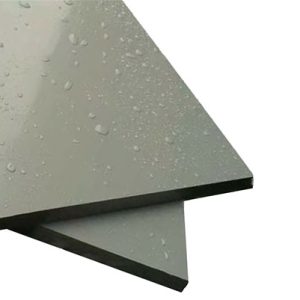

Polypropylene plastic sheets have a polar structure with very high molecular weight. This makes the polypropylene PP sheet highly resistant to chemicals and aqueous solutions of salts, acids and bases. Polypropylene homopolymers have high levels of stiffness and toughness at room temperature. This, along with the water repellence of polypropylene sheets, makes them ideal for mechanical and structural applications. PP sheets with different thicknesses have different applications. So let’s take a look at its thickness range.

PP board is a semi-crystalline material. It is harder and has a higher melting point than PE. Because homopolymer PP is very brittle at temperatures above 0 degrees Celsius, many commercial PP materials are random copolymers with 1-4% ethylene addition or pincer copolymers with higher ratio ethylene content.

Polyflute PP sheet is divided into thin polypropylene sheet and thick polypropylene sheet. The thickness of thin PP sheet is generally 0.5mm – 20mm arbitrarily selected. The thickness of thick PP sheet is 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, and 100mm, because the thickness on the machine cannot be adjusted arbitrarily like thin sheets, so the thicknesses are standard thicknesses, and thick sheets are required. Customers can choose the closest thickness PP board.

Generally, the width of PP solid board on the market is 2000mm, but Polyflute can achieve 3000mm, and the maximum width is mainly determined by the maximum adjustment range of the machine. The recommended sizes are generally: 1500 x 3000mm, 1220 x 2440mm, 1000 x 2000mm.

Before choosing the PP plastic sheet, you should clearly understand the purpose of the sheet. Now PP board has many uses, most of which are to make some display boards, containers, protection devices and some construction and decoration materials. Most of the plates generally used to make display panels and containers require relatively smooth surfaces and relatively high permeability. PP panels used in protective devices have relatively higher requirements, and the ignition point and melting point must meet certain requirements. In addition, when purchasing polypropylene plastic sheets, you should also pay attention to the qualifications of the manufacturers who produce PP panels and whether the after-sales service that can be provided is in place. After-sales service is a very important consideration.

We are a leading PP plastic board manufacturer with rich experience, professional team, and first-class customer service. We always try our best to provide customers with more convenient and professional one-stop overall solutions.

If you need polypropylene plastic sheets or other plastic products, please feel free to contact us at any time! We will get back to you ASAP, and also can arrange a free sample for you!