When considering the differences between Plexiglass Sheets and Acrylic panels, the reality is that they are very similar. But there are some notable differences. Let’s break down the differences between plexiglass, acrylic, and the mysterious third contender Plexiglas.

Plexiglass Sheets are a clear acrylic sheet used exclusively as a generic term to refer to several products manufactured under different names, including the original brand name Plexiglass. When acrylic resin was created in the early 1900s, one of the products produced using it was registered as Plexiglas. Today, many manufacturers produce plexiglass acrylic products sold under the brands Acrylite, Crylux, Lucite, and Perspex.

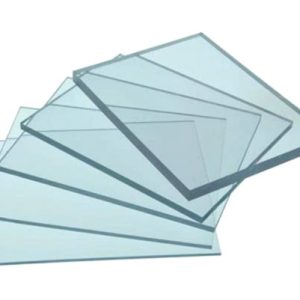

Acrylic is a transparent thermoplastic homopolymer. In other words, it’s a plastic – specifically polymethyl methacrylate (PMMA). Although it is often used in flake form as a replacement for glass, it is also used in a variety of other applications, including casting resins, inks and coatings, medical devices, and more.

While glass is cheaper and easier to recycle than acrylic board, acrylic sheet is stronger, more shatter-resistant, more resistant to elements and corrosion than glass. Depending on its manufacturing process, it may be more scratch-resistant or very impact-resistant than glass.

Therefore, people choose acrylic to replace glass in many applications. For example, spectacle lens manufacturers will use acrylic as the material of choice. Because acrylic, in addition to being less reflective than glass, is also more scratch and shatter resistant, this reduces the amount of glare.

If you are considering, there are differences between plexiglass sheets, perspex panels and acrylic boards. The truth is, there are more similarities than differences. Often, plexiglass and acrylic products known as plexiglass will have very similar qualities. Often, the only difference is in the manufacturing process.

Extrusion process – Extruded acrylic is manufactured using an extrusion process. Acrylic is continuously extruded to form acrylic panels.

Cell casting – The cell casting process involves pouring unreacted acrylic resin between two pieces of glass to form a cell. After the reaction is complete and the acrylic has cured, the operator will remove the glass and acrylic and inspect the acrylic sheet. Because the process requires more time and labor, battery cast acrylic sheets to be more expensive, but are generally higher quality and more durable.

There is only one manufacturing process for plexiglass products – battery casting process manufacturing. So if you pay more for having plexiglass panels, you are paying more than just the brand name. You’re paying for a more substantial manufacturing process, and often a product customized to your needs.

We are a leading acrylic sheet manufacturer with rich experience, professional team, and first-class customer service. We always try our best to provide customers with more convenient and professional one-stop overall solutions.

Now that you know the difference between plexiglass and acrylic, this should help you plan your future use of both products. If you are interested in learning more about commercial plexiglass sheets services, please contact Polyflute®.