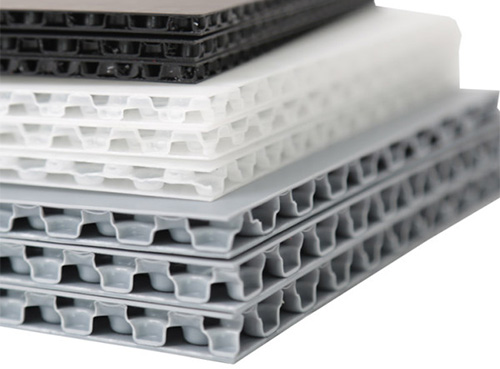

PP bubble guard sheets are made of Polypropylene consist of three polypropylene layers. The middle layer is a special honeycomb structure by thermoforming. The outer and inner layer, which holds the bubble layer that provides a very light and stable tri-laminate structure. With co-extrusion and laminating technologies, we can add different kinds of materials to polypropylene honeycomb panels, creating innovative new products for different applications.

Applications of polypropylene honeycomb

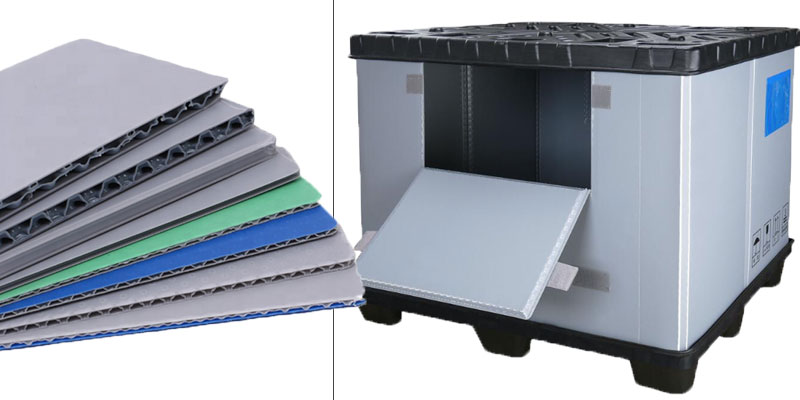

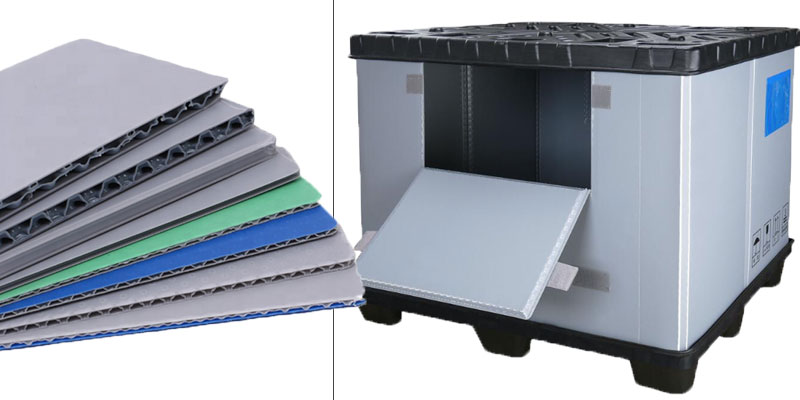

- Logistics industry– pp honeycomb panel can be used as liners, container walls and dividers

- Packaging industry – pp bubble guard sheets as pallet liners, layer pads/tier sheets or post-processing into various types of boxes

- Advertising industry – such as stand walls, billboards, signs, display boards, screen printing supplies

- Automotive industry – pp honeycomb sandwich panel as back wall panel, spare wheels housing

- Home appliance industry – such as the back wall of a refrigerator or the protection bottom of a washing machine

- Decoration industry – polypropylene honeycomb core can be also used as floor protection during construction to prevent ink, paint from dirtying floors, doors and windows

- other industry

Advantages of Polyflute® PP Bubble Guard Sheets

- Light weight, high strength, very durable

- Cost-effective, reusable, 100% recyclable

- The material is the high-quality polypropylene, non-toxic and environmentally friendly

- Excellent stability, the board is not easy to break

- Corrosion resistance, water resistance, alkali resistance

- Polypropylene honeycomb panels are also impact and friction resistant

- In addition to standard products, we also provide free design, customized special plastic honeycomb panels

General specifications of polypropylene honeycomb panels

- Size: width less than 1560mm, any length

- Thickness: 3.5mm-13mm

- Density: 1050-6500g/sm

- Color: blue, white, gray, black, or custom

About us

Our company has been adhering to the business philosophy of “pursuing excellent quality, preferential prices, and fast delivery”. All of our colleagues will make long-term unremitting efforts to continuously improve corrugated plastic products quality, safeguard customer interests, and wholeheartedly provide our customers with first-class products and first-class services.

If you want to bulk pp honeycomb board / pp bubble guard sheets, welcome to contact us now!

| Welcome to contact us now.

We will get back to you within 8 hours. We will offer latest price and free sample.